Long-persistence luminescent material and its preparing method

A technology of long afterglow luminescence and luminescent materials, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of weak recognition ability of the human eye, slow light absorption speed, less luminous color, etc., to improve the application performance of products and reduce wear brightness. Loss, powder loose and brittle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Raw materials

[0070] The raw materials of the above composition are fully mixed by ball milling, put into the crucible, put into the electric furnace, and sintered in an oxidizing atmosphere at 900°C for 10 hours. After cooling, take out the crucible. After the sintered body in the crucible is naturally cooled to room temperature, It is sintered in a furnace filled with 95% hydrogen, 3% nitrogen and 2% hydrogen sulfide mixed gas. The furnace temperature is raised from 400°C to 1400°C within 10 hours, and the temperature is kept at 1400°C for 5 hours. . After that, the furnace temperature was reduced to 200°C within 6 hours, and the crucible was taken out. After the sintered body in the crucible was naturally cooled to room temperature, it was crushed, ground with a ball mill, and then sieved with a 325-mesh sieve for luminescent particles. Invented luminescent material SrO·0.002 SrS·Al 2 O 3 ·0.02B 2 O 3 ·0.01P 2 O 5 :0.004Eu. This material is labeled as Example...

Embodiment 1-7

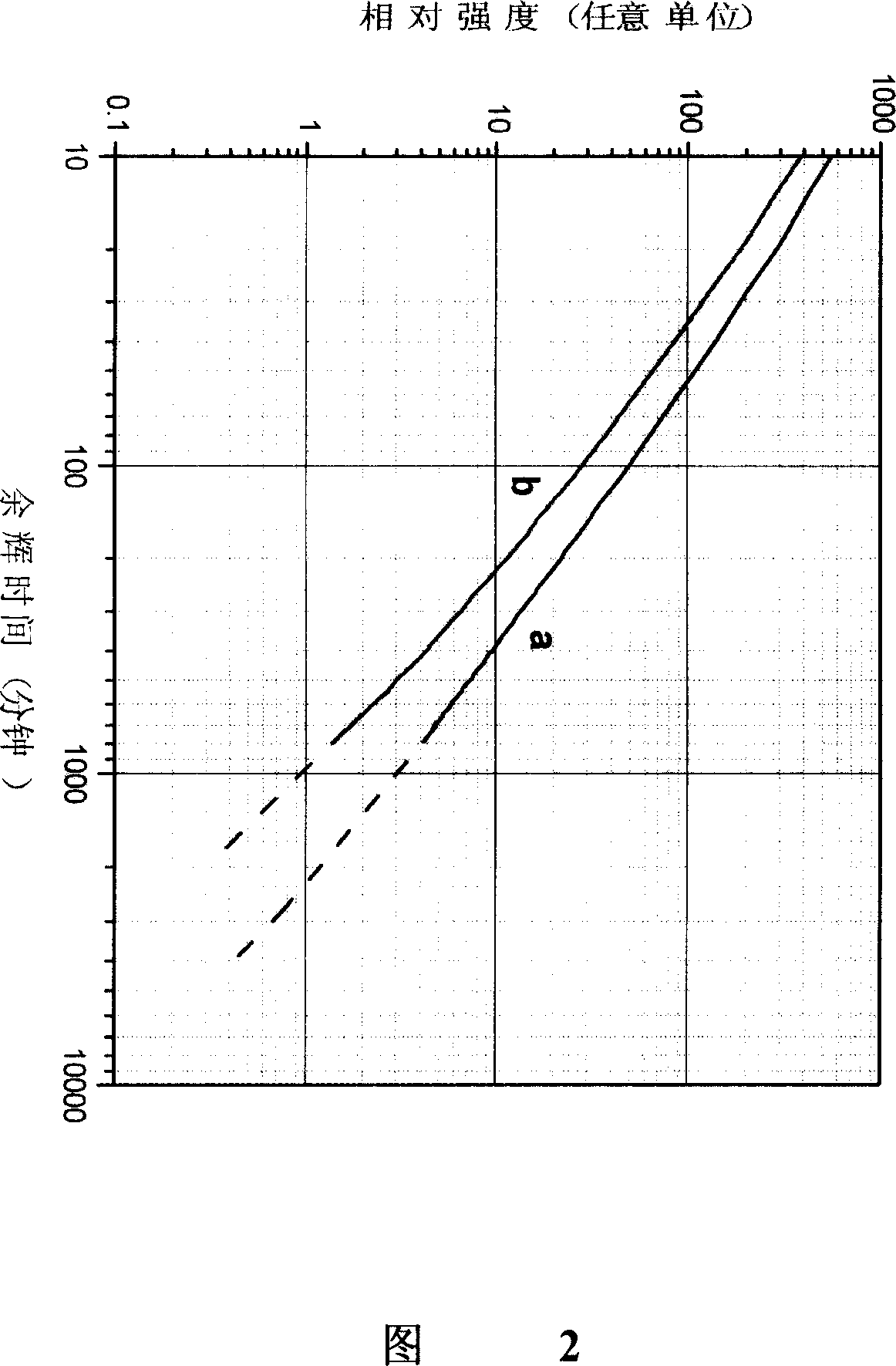

[0072] The long-lasting luminescent material of Examples 2-7 with yellow-green luminescent color was prepared by using the same method as that of the luminescent material of Example 1 and compared with the comparative sample A(SrO·Al) prepared in the prior art. 2 O 3 ·0.02B 2 O 3 :0.004Eu) Comparison of long afterglow luminescent materials. The material compositions of Examples 1-7 are listed in Table 1. In Table 1 and the table of examples at the back of this specification, "comparative examples" are corresponding long-lasting luminescent materials prepared according to the prior art, and are abbreviated as "comparative samples". Table 1 shows the composition of each luminescent material and the relative brightness of the corresponding luminescent powder and luminescent film 10 minutes after stopping excitation, relative to the powder and luminescent film of Comparative Sample A indicated as 100.

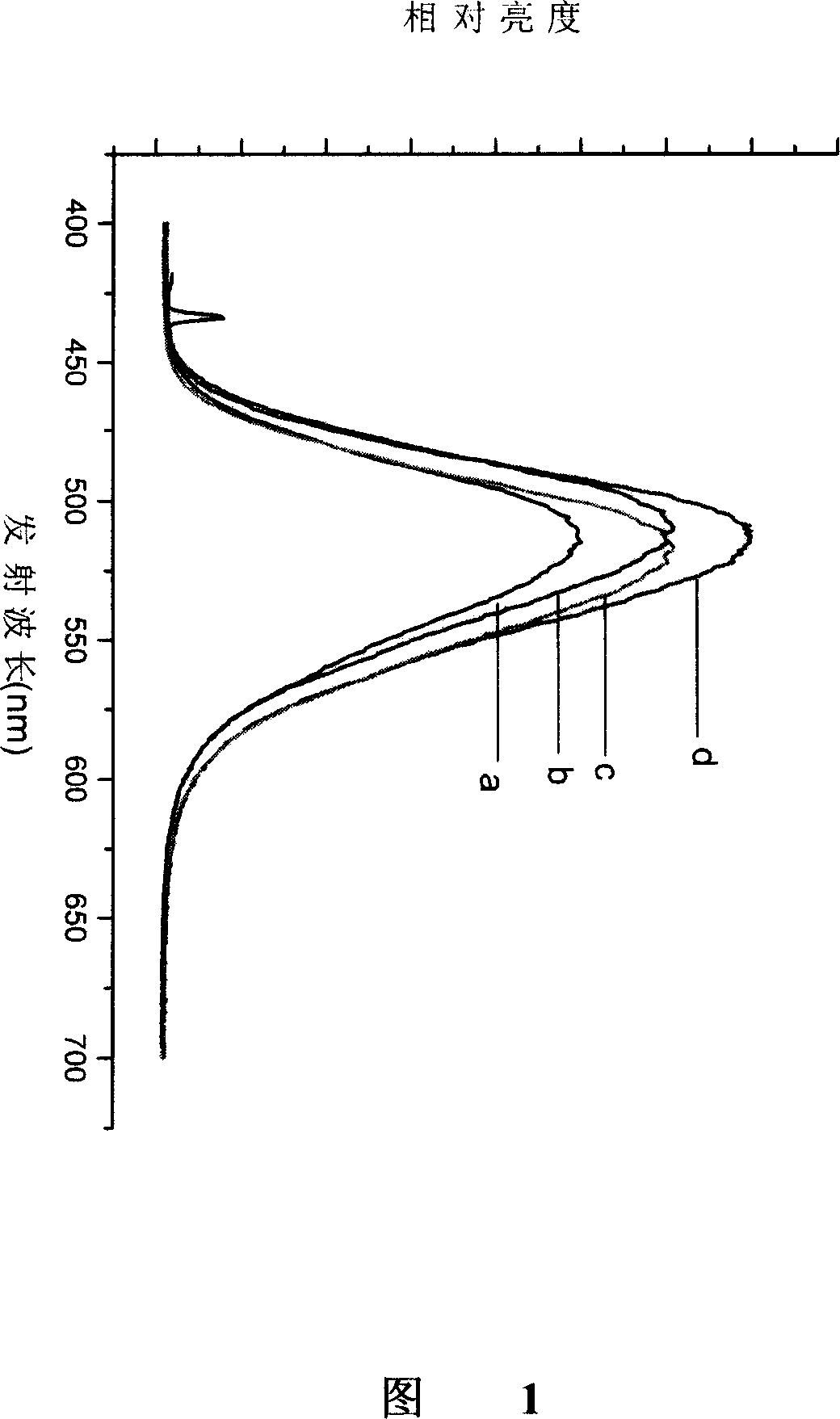

[0073] Figure 1 illustrates the emission spectra of the luminescent powders of Exa...

Embodiment 8-12

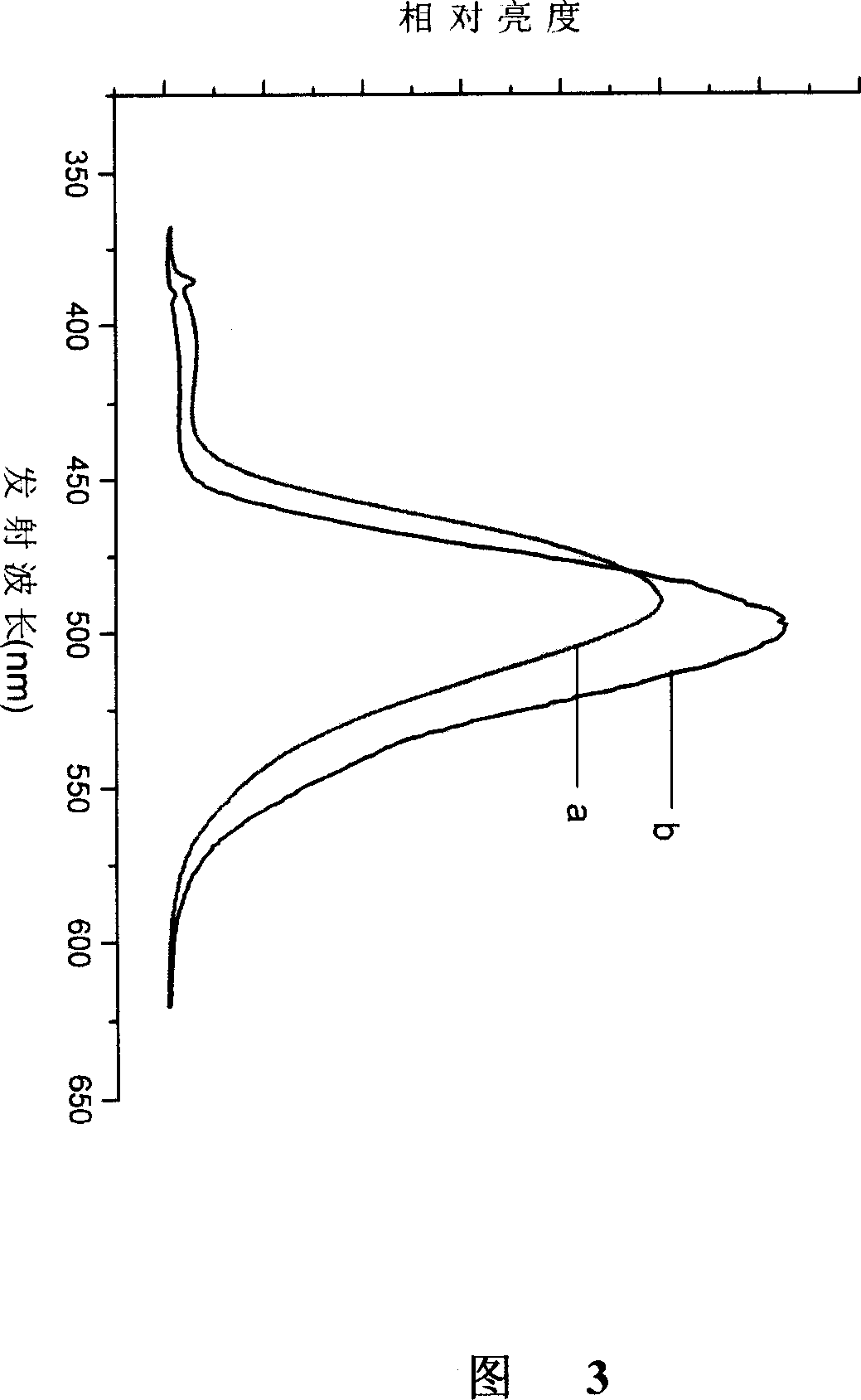

[0078] The long-lasting luminescent materials of Examples 8-12 with different molar contents of europium and different molar contents of dysprosium were prepared by using the same method as the preparation of the luminescent material of Example 1, and the corresponding comparative samples were prepared according to the prior art and used the same The powder routine test and film routine test method measure the luminous brightness of these luminescent powder and luminescent film 10 minutes after stopping excitation. Table 2 lists the results of the examples and comparative samples and their relative brightness. The addition of europium with different molar content and dysprosium with different molar content has been a consensus in the industry on the influence of the long-lasting luminescent material, which can make the powder body and the luminescent film of the long-lasting luminescent material have different brightness. In the present invention, due to the addition of sulfur and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com