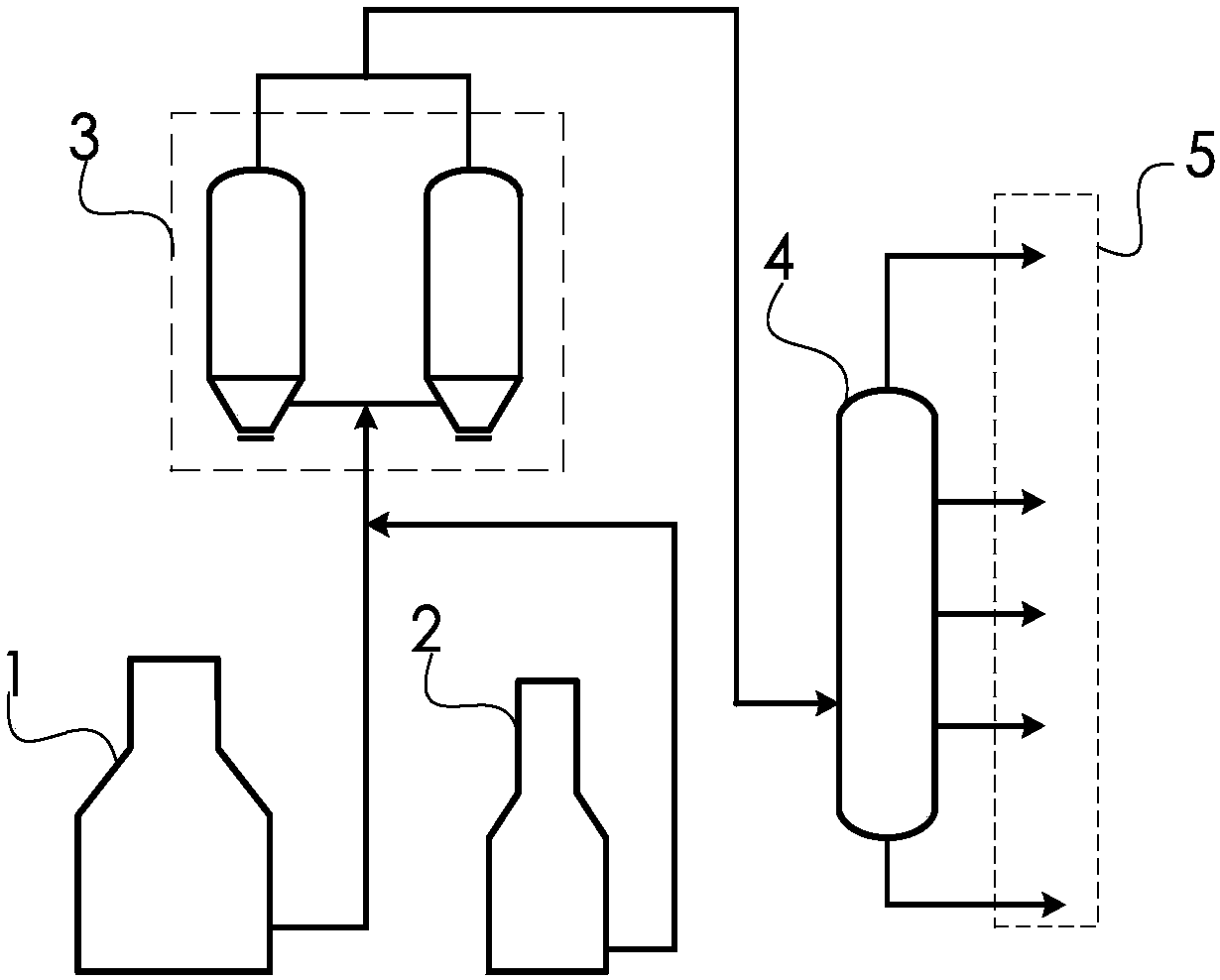

Delayed coking apparatus and method for processing catalytic oil slurry

A technology of delayed coking and catalytic oil slurry, applied in the field of delayed coking process, can solve the problems of increasing economic benefits, easy abrasion of machines and pumps, incapability of long-term operation, etc., and achieves the effect of high operational flexibility and extended operation cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

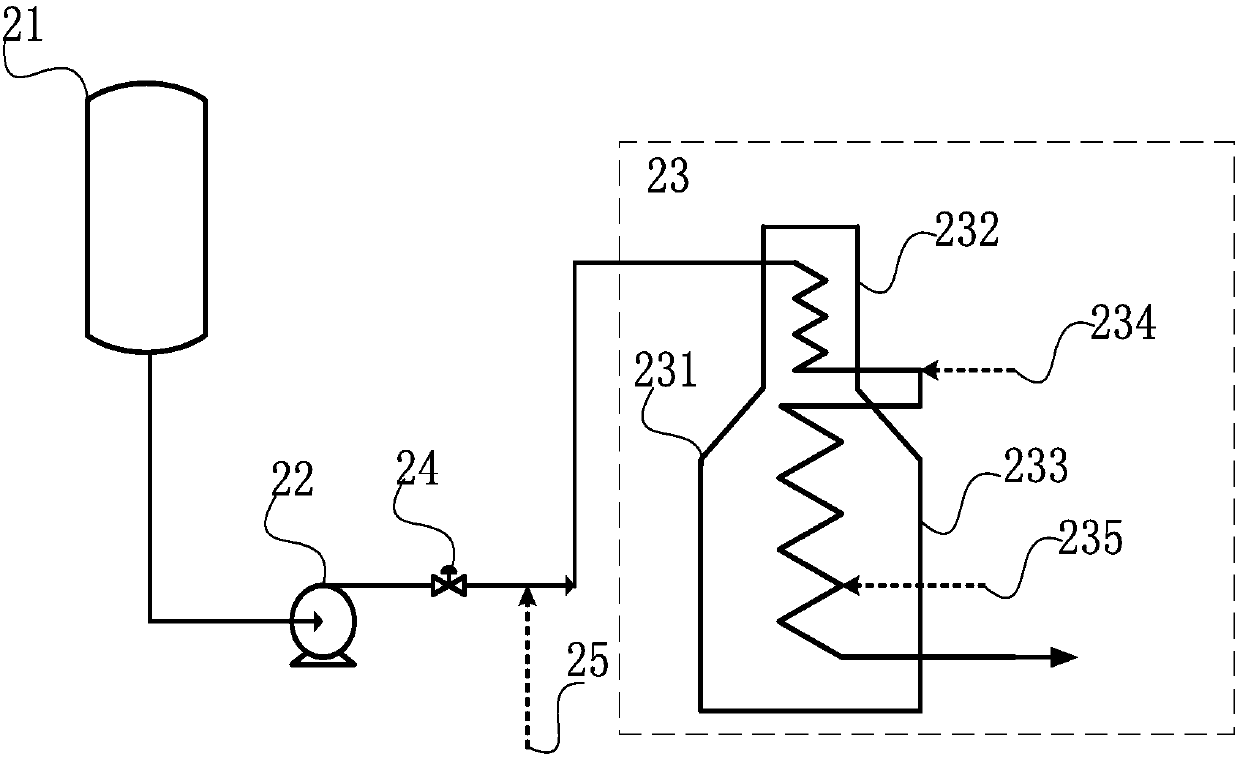

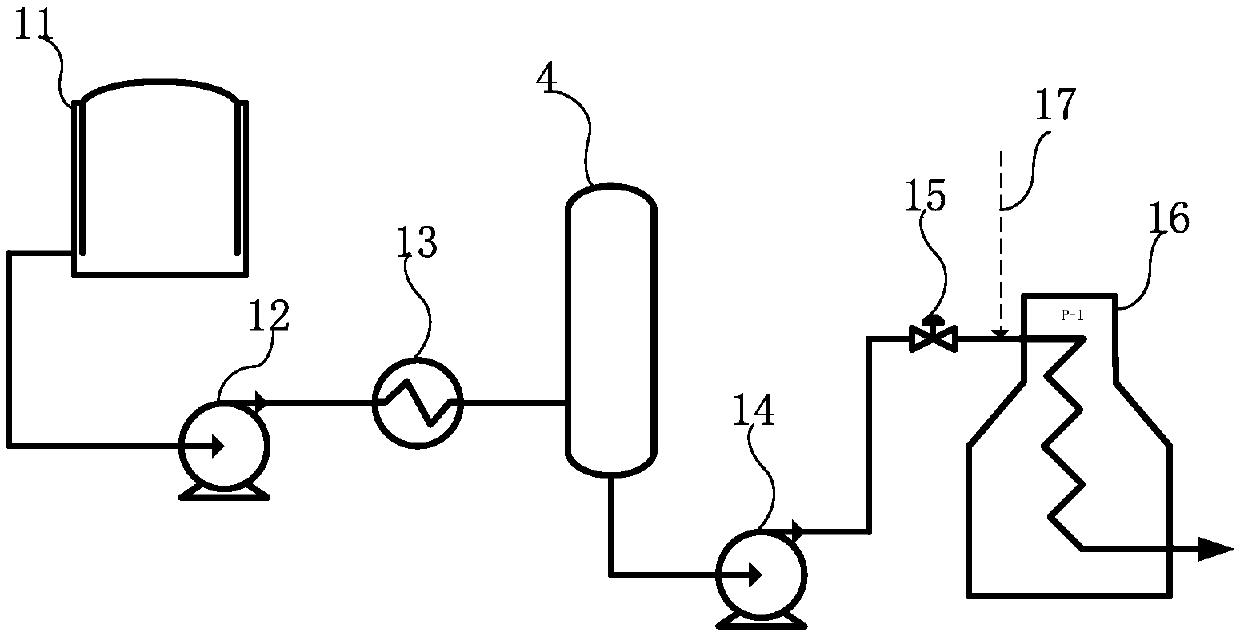

[0067] (A) The external catalytic oil slurry raw material is first sent to the catalytic oil slurry buffer tank 21, and the catalytic oil slurry raw material in the catalytic oil slurry buffer tank 21 is transported to the oil slurry heating furnace 23 through the oil slurry pump 22, and is passed through the oil slurry flow control The valve 24 controls the flow rate to be 30-32t / h, and the catalytic oil slurry with a stable flow rate enters the convection chamber 232 of the oil slurry heating furnace 23 to be heated, and injects a steam (390°C, 3.5MPa, steam Flow control is 500kg / h), thereby improves the flow velocity of the oil slurry that convection chamber 232 comes out; Coking speed, inject a stream of water vapor (390°C, 3.5MPa, steam flow rate is 400kg / h at the penultimate sixth row of radiant tubes in the radiation chamber 233 through the second steam injection hole 235, after calculation: the penultimate row The temperature of the oil slurry at the radiant tube is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com