Vulcanization method of addition type silicone rubber

A technology of addition type and silicone rubber, which is applied in the field of vulcanization of addition type silicone rubber. It can solve the problems of affecting the physical properties of the rubber material, easy to break and brittle, and hardening of the rubber material, so as to reduce the vulcanization temperature, increase the vulcanization rate, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

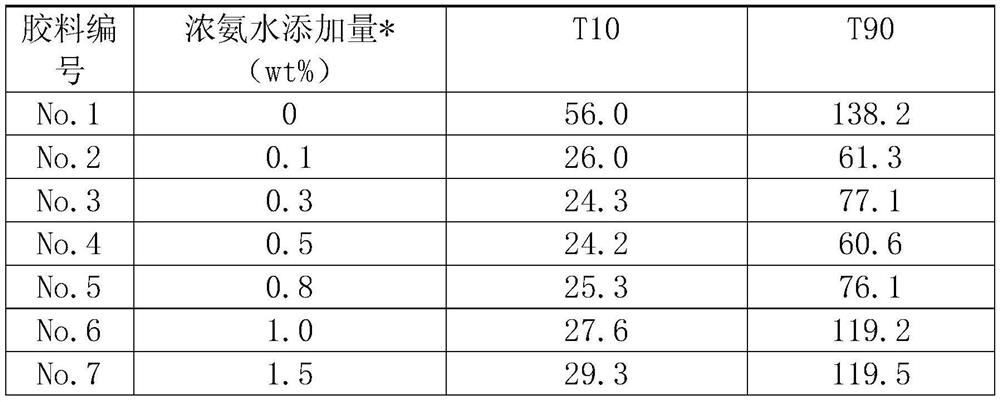

Embodiment 1

[0025] In this example, addition type liquid silicone rubber CNH-LIMS-40A (component A) and CNH-LIMS-40B (component B) produced by Shin-Etsu Co., Ltd. are used. The liquid silicone rubber is divided into two components, A and B. Among them, in addition to the rubber base, component A also contains platinum-based catalysts and other substances, and component B contains not only the rubber base, but also cross-linking agents such as hydrogen-containing silicone oil. Take two components A and B of equal weight, and take 0.5% of the total weight of the two components A and B ammonia water with a concentration of 25% to 28%, and mix A component, B component and ammonia water evenly. First use a rotorless vulcanizer to measure its vulcanization curve at 110°C, and measure its positive vulcanization time T90 to be 80s, then use a flat vulcanizing agent to vulcanize under pressure at 110°C, and the vulcanization time is 80s to obtain a standard hardness block with a thickness of 6mm. ...

Embodiment 2

[0029] The making of sizing material is the same as implementation 1. However, the vulcanization condition for preparing standard hardness blocks was 100°C×140s. It was found that the Shore A hardness of the vulcanized rubber added with ammonia water was 40, and the surface was dry. However, the Shore A hardness of the vulcanizate of the comparison compound without adding ammonia water is only 31, and the surface is not dry, which is characterized by sulfur deficiency.

[0030] Example 2 shows that adding ammonia water can properly reduce the vulcanization temperature.

Embodiment 3

[0032] Take 100g each of CNH-LIMS-40A and CNH-LIMS-40B, put them in glass crystallization dishes with a diameter of 150mm respectively, and put the glass crystallization dishes in a glass vacuum desiccator (no need to vacuum, use this kind of glassware, just for It is convenient for the drying chamber in the glass vacuum desiccator to communicate with and close with the outside world).

[0033] Treatment of liquid silicone rubber with ammonia gas: Keep the glass vacuum desiccator open to the outside world. Put 2g to 5g of liquid ammonia in the desiccator, cover the lid of the desiccator, and close the desiccator when the liquid ammonia in the desiccator evaporates completely. After standing for 48 hours, mix the two components evenly, and then test the vulcanization curve and the hardness of the vulcanized rubber.

[0034] The obtained results are similar to those of Example 1. Compared with the liquid silicone rubber not treated with ammonia gas, the liquid silicone rubber t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com