Silane-Modified Silcic Acid, Method For The Production And Use Thereof

A silica and silane modification technology, used in silica, silica, chemical instruments and methods, etc., can solve the problems of poor dispersion, poor wear resistance, high Mooney viscosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

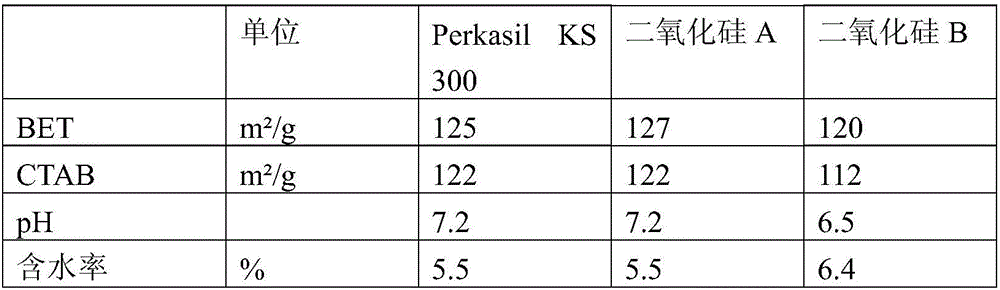

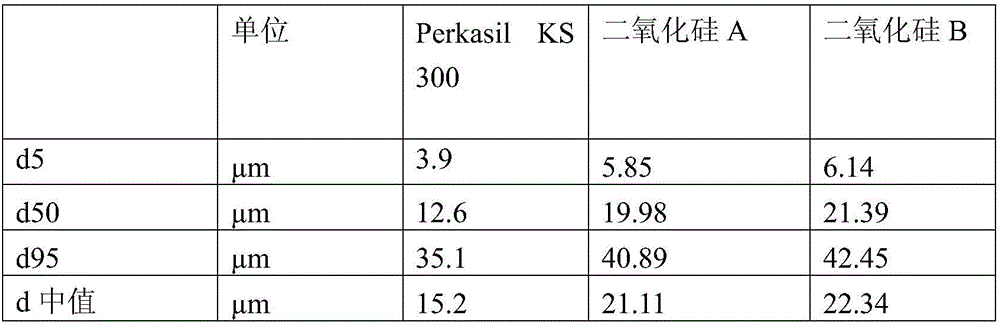

[0146] Embodiment 1: the preparation of silica A

[0147] In the stainless steel reactor that has propeller stirring system and jacket heating, at first load the water glass (density 1.348kg / L, 27.0%SiO2 of 1510L water and 46kg 2 , 8.05% Na 2 O). Then, after vigorous stirring at 92° C. for 90 minutes, 6.655 kg / min of the above-mentioned water glass and about 0.832 kg / min of sulfuric acid (density 1.83 kg / L, 96% H 2 SO 4 ). The metered addition of the sulfuric acid was adjusted such that a base number of 7 prevailed in the reaction medium. Subsequently, the addition of water glass was stopped and further sulfuric acid was fed in until a pH of 8.5 was reached (measured at room temperature). After standing for about 30 minutes, further sulfuric acid was metered in until a pH of 4.5 was reached. The resulting suspension was filtered with a membrane filter press, washed with water and dried.

Embodiment 2

[0148] Embodiment 2: the preparation of silica B

[0149] In the stainless steel reactor that has propeller stirring system and jacket heating, at first load the water glass of 1550L water and 141.4kg (density 1.348kg / L, 27.0%SiO 2 , 8.05% Na 2 O). Then, after vigorous stirring at 92°C for 100 minutes, 5.505 kg / min of the above-mentioned water glass and about 0.65 kg / min of sulfuric acid (density 1.83 kg / L, 96% H 2 SO 4 ). The metered addition of the sulfuric acid was adjusted such that a base number of 20 prevailed in the reaction medium. Subsequently, the addition of water glass was stopped and further sulfuric acid was fed in until a pH of 9.0 was reached (measured at room temperature). The addition of sulfuric acid was stopped and the resulting suspension was stirred at 90° C. for a further 60 minutes. Subsequently, the addition of sulfuric acid was started again and a pH of 3.5 (measured at room temperature) was achieved. The resulting suspension was filtered with ...

Embodiment 3

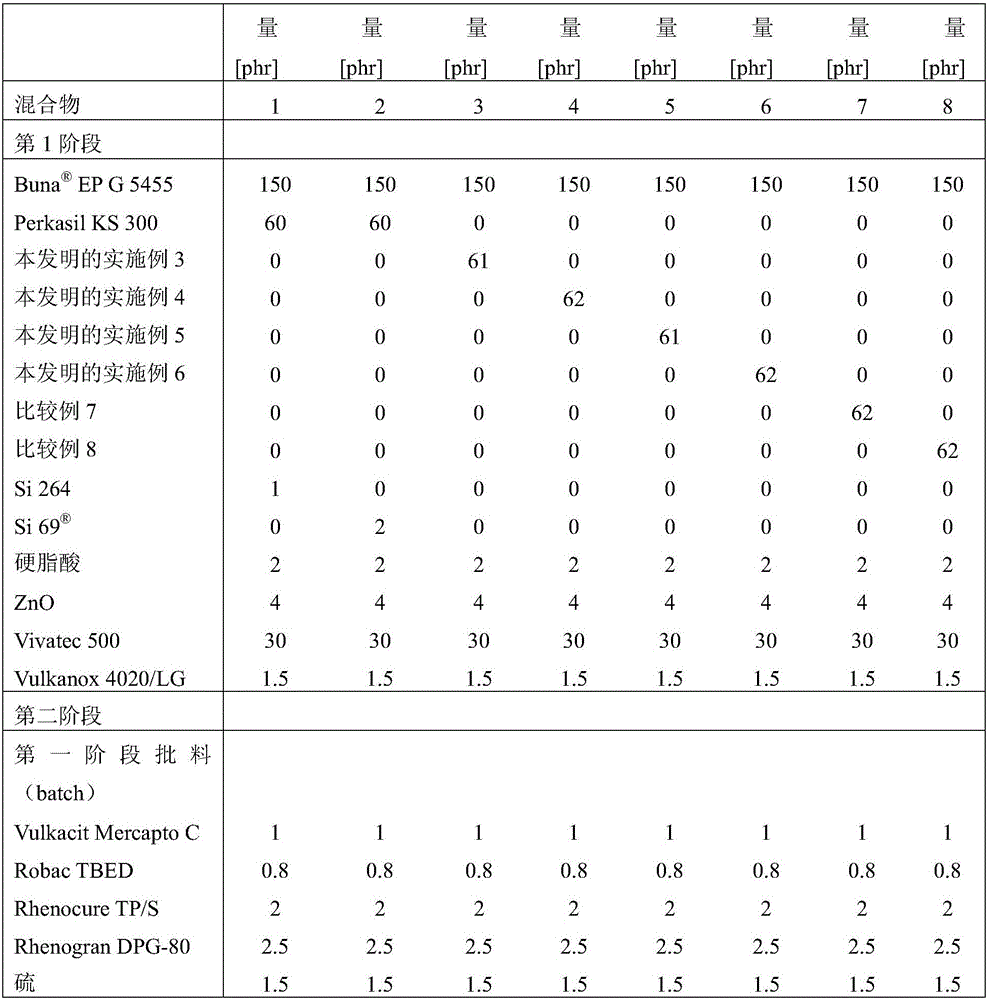

[0157] Example 3: Preparation of silane-modified silica of the present invention (silica A+Si264)

[0158] The Henschel mixer is first charged with the appropriate amount of filler and the mixer is started. Set the Blend Tool Speed to a suitable value. The silane is sprayed into the mixer by means of an ultrasonic nozzle. Then, the mixer outlet valve was opened and the product was discharged from the mixer.

[0159] The mixing conditions are listed in Table 3. The silica used was silica A (Example 1) and the silane was Si264.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com