Preparation formula of insulation sheath for cable

A technology of insulating skin and formula, which is applied to rubber insulators, organic insulators, etc., and can solve problems such as aging of insulating skins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

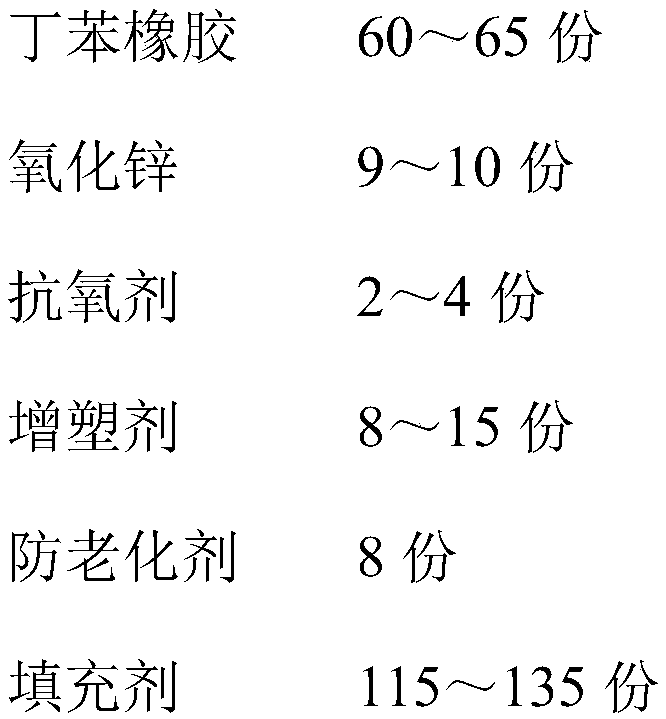

[0018] A kind of insulation skin preparation formula for electric cables, by weight, its raw material composition is as follows:

[0019] 64 parts of styrene-butadiene rubber, 10 parts of zinc oxide, 2 parts of antioxidant, 13 parts of plasticizer, 8 parts of anti-aging agent, and 135 parts of filler.

[0020] The antioxidant is tetrakis[methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester;

[0021] The plasticizer is a mixture of 52-degree chlorinated paraffin and dioctyl phthalate;

[0022] Antiaging agent is N-isopropyl-base p-phenylenediamine;

[0023] The filler is a mixture of talc and calcium carbonate.

Embodiment 2

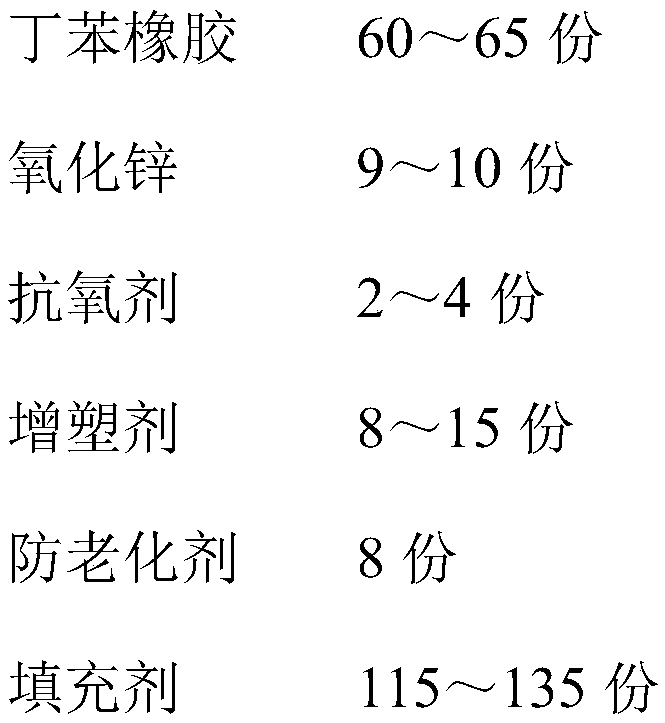

[0025] A kind of insulation skin preparation formula for electric cables, by weight, its raw material composition is as follows:

[0026] 63 parts of styrene-butadiene rubber, 9 parts of zinc oxide, 2 parts of antioxidant, 12 parts of plasticizer, 8 parts of anti-aging agent, and 125 parts of filler.

[0027] The antioxidant is tetrakis[methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester;

[0028] The plasticizer is a mixture of 52-degree chlorinated paraffin and dioctyl phthalate;

[0029] Antiaging agent is N-isopropyl-base p-phenylenediamine;

[0030] The filler is a mixture of talc and calcium carbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com