Production method of modified yttrium oxide

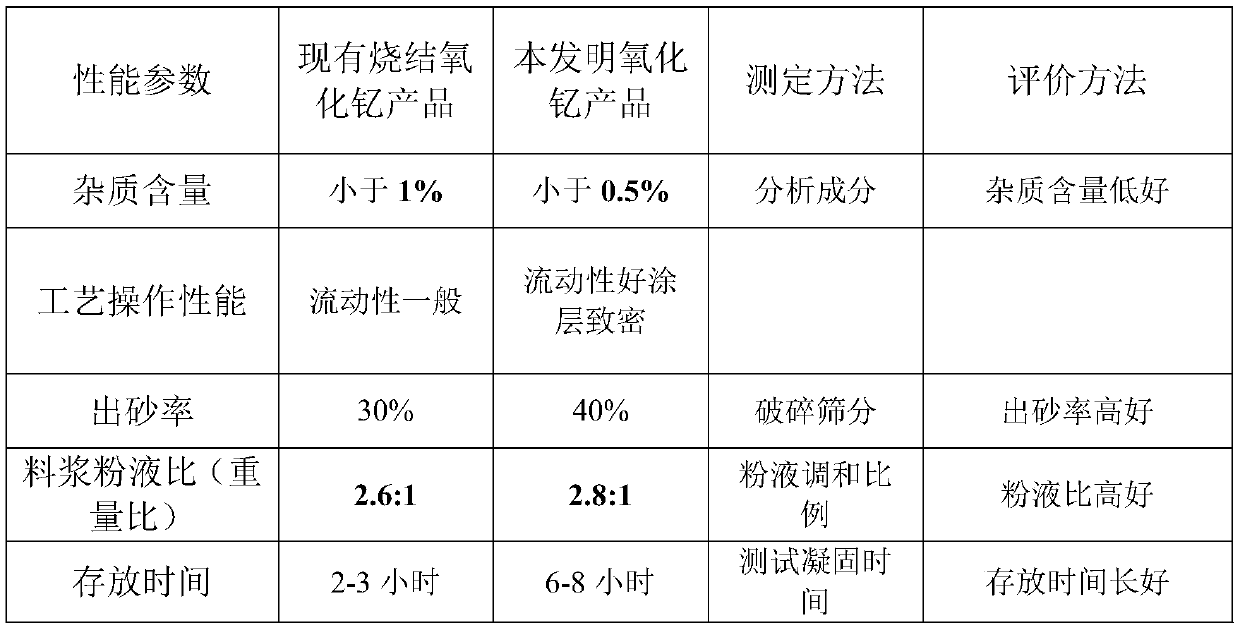

A manufacturing method and technology of yttrium oxide, applied in the field of inorganic materials and its manufacturing, can solve problems such as poor process performance, low sanding rate of fused yttrium oxide, and low storage time of coating slurry powder liquid, etc., to improve the process Operability, high powder-to-liquid ratio, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of manufacture method of modified yttrium oxide, manufacture method comprises the steps:

[0031] Step 1: batching, taking 2-17 parts by weight of zirconia and 83-98 parts by weight of yttrium oxide, pulverizing them to a size smaller than or equal to 100 mesh, and mixing the pulverized zirconia and yttrium oxide evenly to obtain a mixed charge;

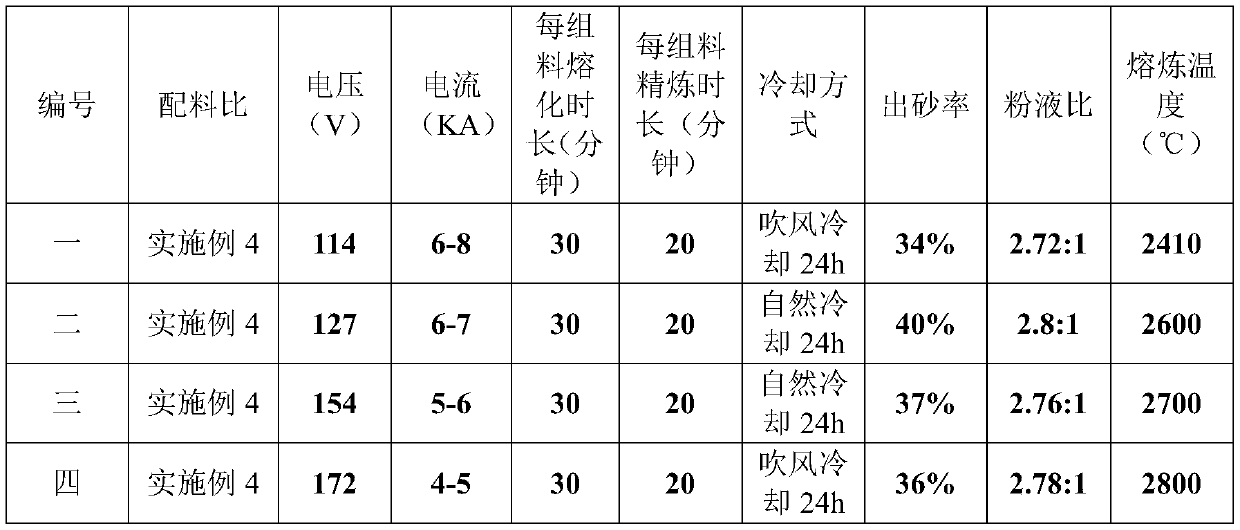

[0032] Step 2: Smelting, put the mixed charge into the electric arc furnace for smelting, the melting temperature is greater than or equal to 2410°C, after T 1 min time until the mixed charge is completely melted to obtain the modified yttrium oxide in molten state;

[0033] Further also include the following steps:

[0034] Step 3: cooling down, cooling the modified yttrium oxide melted in step 2 to room temperature;

[0035] Step 4: Crushing, smashing and sorting the modified yttrium oxide after cooling in step 3, the purpose of picking is to pick out the lumps that have not melted well on the surface and have raw m...

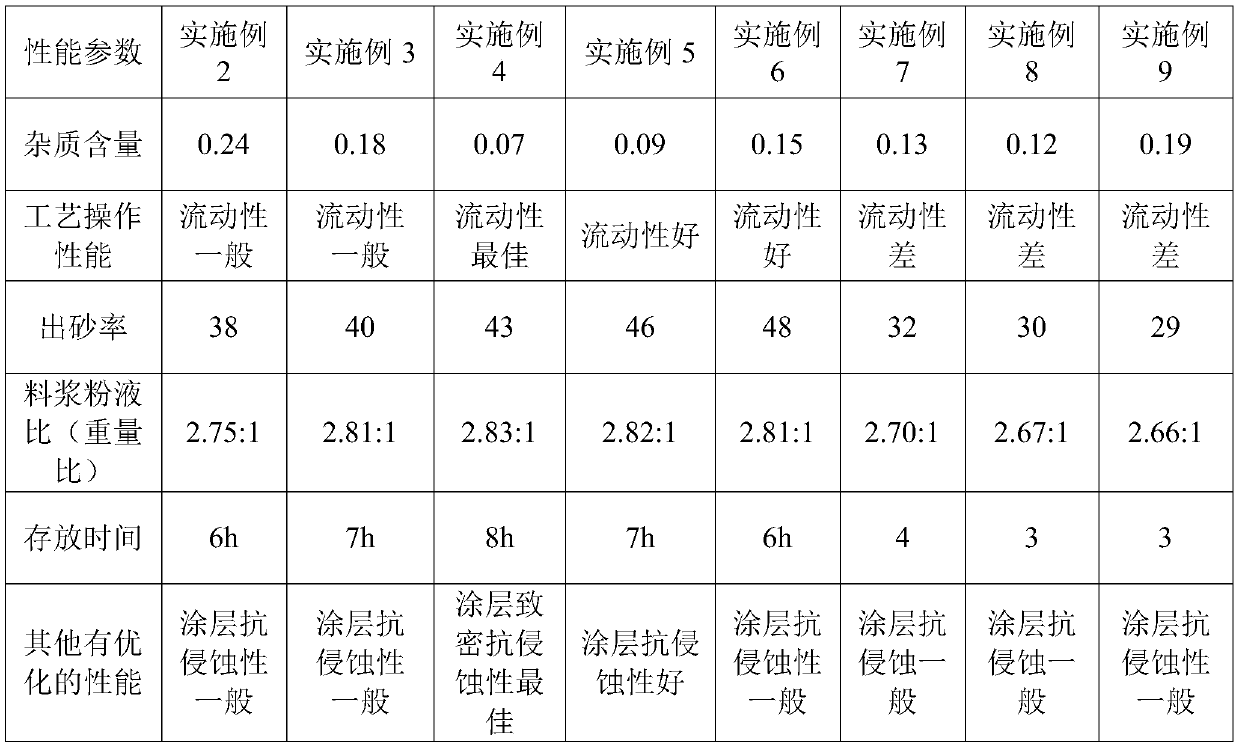

Embodiment 2

[0045] Step one, the ingredients will contain ZrO 2 3 parts by weight of fused desiliconized zirconium with a weight content greater than 99% and 97 parts by weight of yttrium oxide with a weight content of 3N are put into a mixer and mixed evenly to make a mixed charge.

[0046] Step 2, smelting, put the mixed charge into the electric arc furnace in batches, for example: smelting in a three-phase AC electric arc furnace until the charge is completely melted, and continue refining after melting. The time ratio of melting and refining is 3:2, each charge Carry out melting for 30 minutes, refining for 20 minutes, and the melting temperature is 2600°C.

[0047] Step 3, lowering the temperature, cooling down the melted melt to room temperature.

[0048]Step 4, smashing, smashing and picking the melt. The frit after picking is processed into sand and fine powder with the particle size required by the user by crushing equipment. The size above 100 mesh is less than 100 mesh. The c...

Embodiment 3

[0050] will contain ZrO 2 5 parts by weight of natural baddeleyite with a weight content greater than 99% and 95 parts by weight of yttrium oxide with a weight content of 4N are put into a mixer and mixed evenly to make a mixed charge. Other steps are the same as in Embodiment 1 and will not be repeated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com