Sand washing system and washed sand preparing process

A preparation process and water-washing sand technology, applied in the field of water-washing sand, can solve the problem of high mud content and achieve the effects of high sand production rate, reduced mud content and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

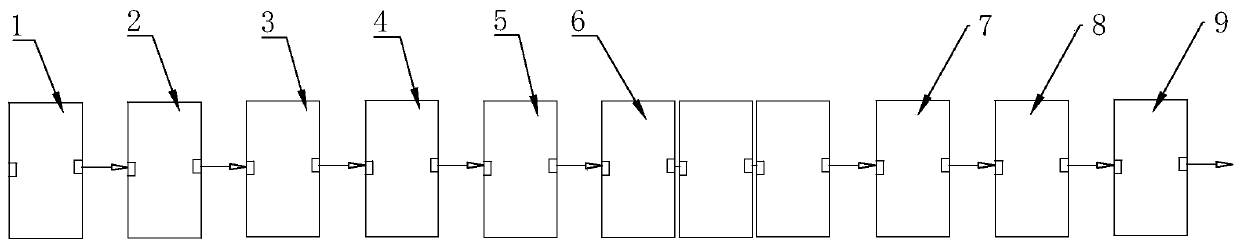

[0046] Such as figure 1 As shown, a water washing sand system includes a screening machine 1, a sand fishing machine 2, a conveyor belt 4, a first dewatering screen 3, a second dewatering screen 7, a drum machine 5, a wheel sand washing machine 6, a static tank 8 and The third dehydration screen 9. The screening machine 1 is used to separate sand and gravel, and the sand dredger 2 is used to wash the separated sand for the first time. A water delivery pipe is installed at the feeding port of the sand dredge machine 2, and the water delivery pipe transports water to the sand dredge. 2. When the sand enters the sand dredger 2, it is immediately mixed with water for the first sand washing. The first dewatering screen 3 is used for the first dehydration of the sand after the first elutriation, and the conveyor belt 4 is used for transporting the first dewatered sand to the circular tumbler 5 . Circular drum machine 5 is used for second time elutriating sand. The tumbling machin...

Embodiment 2

[0049] Such as figure 1 Shown, a kind of washing method of washing sand:

[0050] S1: Screening, put 100kg of raw materials into the screening machine 1 for screening, and screen out sand with a particle size of less than 5mm;

[0051] S2: For the first elutriation, the sand screened out by the screening machine 1 is transported to the sand dredge machine 2, and water is injected to perform the first elutriation on the sand;

[0052] S3: Dehydration, the sand after the first elutriation is transported to the first dewatering screen 3 for dehydration, and the sand is sent to the conveyor belt 4 after dehydration;

[0053] S4: For the second elutriation, the conveyor belt 4 sends the sand into the tumbler 5, and adds 100kg of water (which contains 10% of domestic sewage, and the nitrogen source content in the domestic sewage) at the feed inlet of the tumbler 5 5-10%, carbon source content is 10-15%), pH regulator (made by mixing 30g Alcaligenes (A.faecalis) with 2.4kg molar co...

Embodiment 3

[0057] Such as figure 1 Shown, a kind of washing method of washing sand:

[0058] S1: Screening, put 100kg of raw materials into the screening machine 1 for screening, and screen out sand with a particle size of less than 5mm;

[0059] S2: For the first elutriation, the sand screened out by the screening machine 1 is transported to the sand dredge machine 2, and water is injected to perform the first elutriation on the sand;

[0060] S3: Dehydration, transport the sand after the first elutriation to the first dewatering screen for 3 dehydration, and send the sand to the conveyor belt 4 after dehydration;

[0061] S4: For the second elutriation, the conveyor belt 4 sends the sand into the tumbler 5, and adds 100kg of water (which contains 10% of domestic sewage, and the nitrogen source content in the domestic sewage) at the feed inlet of the tumbler 5 5-10%, carbon source content is 10-15%), pH regulator (made by mixing 20g of Alcaligenes (A.faecalis) with 1.6kg of glucose so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com