A method for combining cyclones for tailings dry discharge

A cyclone and secondary cyclone technology, applied in chemical instruments and methods, wet separation, recycling technology, etc., can solve the problem that the yield of sedimentation can only reach about 75%.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

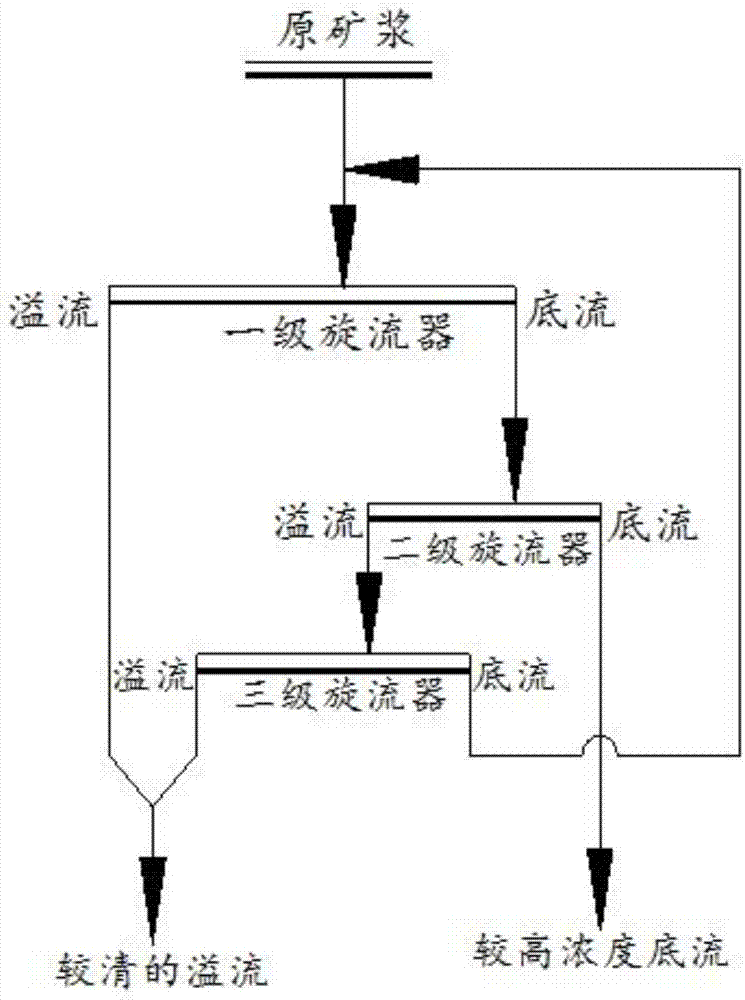

[0021] Such as figure 1 As shown, for the copper tailings of a mining company, the dry tailings volume is 5 tons / hour, the slurry concentration is 15%, the slurry concentration is the mass fraction of solids in the entire slurry, and the copper tailings particle size is greater than 325 mesh The content accounts for 95% of the whole tailings slurry. The copper tailings are dry-discharged by using a cyclone combination method, and the specific steps are as follows:

[0022] 1) Transport the copper tailings slurry to the primary cyclone. The model of the primary cyclone is XCⅡ200×3 (1 group). The copper tailings slurry is divided into underflow and overflow in the primary cyclone. The underflow is a coarse particle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com