A core-shell structure nano-copper cerium composite oxide catalyst, preparation method and application

A composite oxide, shell structure technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of Cubic Cu by Liquid Phase Reduction 2 O particles:

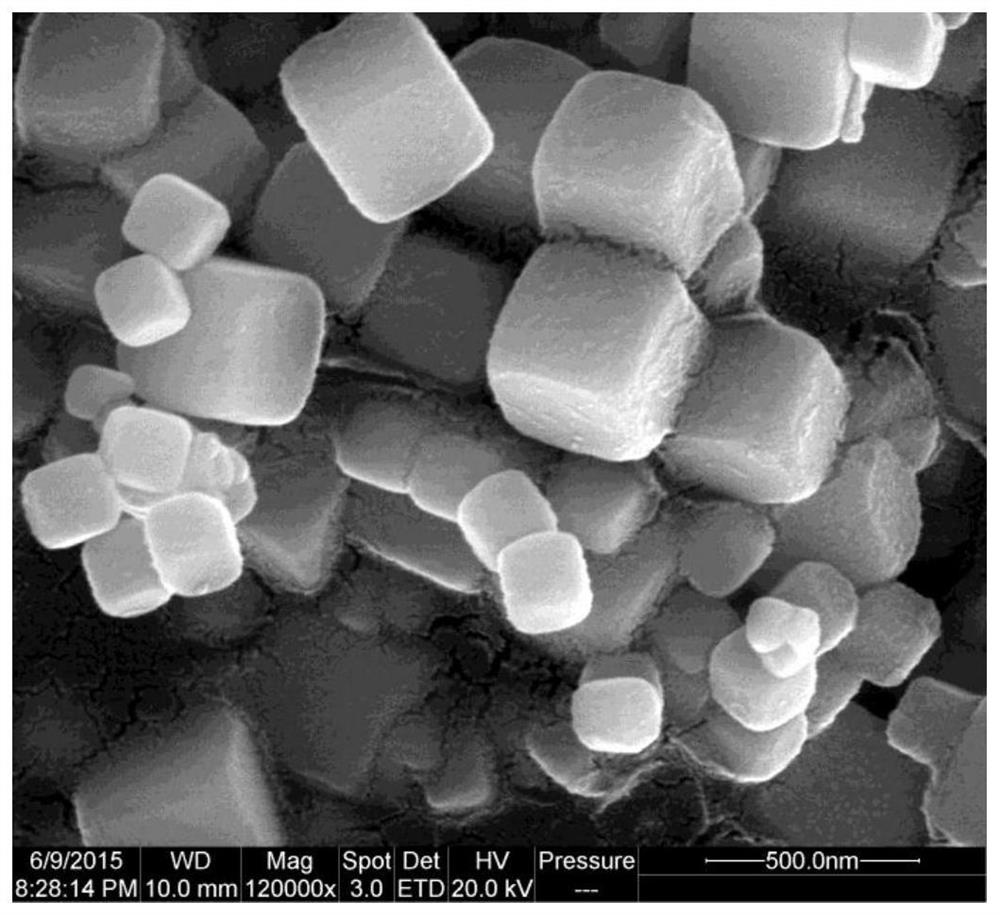

[0029] (1) Firstly, copper nitrate was dissolved in 900ml of deionized water to prepare a solution with a concentration of 0.01mol / L. At the same time, 0.09g of citric acid particles were added to the solution, and stirred at room temperature for 0.5h. Then 2.0 mol / L sodium hydroxide solution was gradually dropped into the mixed solution until pH=11. After stirring at room temperature for another 0.5 h, 0.6 mol / L ascorbic acid solution was added to the solution, at this time, the mixture was heated to 40° C. and kept constant, and stirring was continued for 3 h. Cu obtained by centrifugation 2 O samples were cleaned with deionized water and alcohol. Finally, the catalyst was dried in a vacuum environment for 12 h. Scanning electron microscopy of the prepared samples as figure 1 , the results show that the catalyst presents a typical Cu 2 O cubic crystal structure and smooth surface, particle edge s...

Embodiment 2

[0033] Change the calcination temperature to 300°C and 500°C, and other steps are the same as in Example 1 to obtain the catalyst CuO@CeO 2 -300 and CuO@CeO 2 -500, the morphology of the catalyst is still a nano-core-shell structure.

Embodiment 3

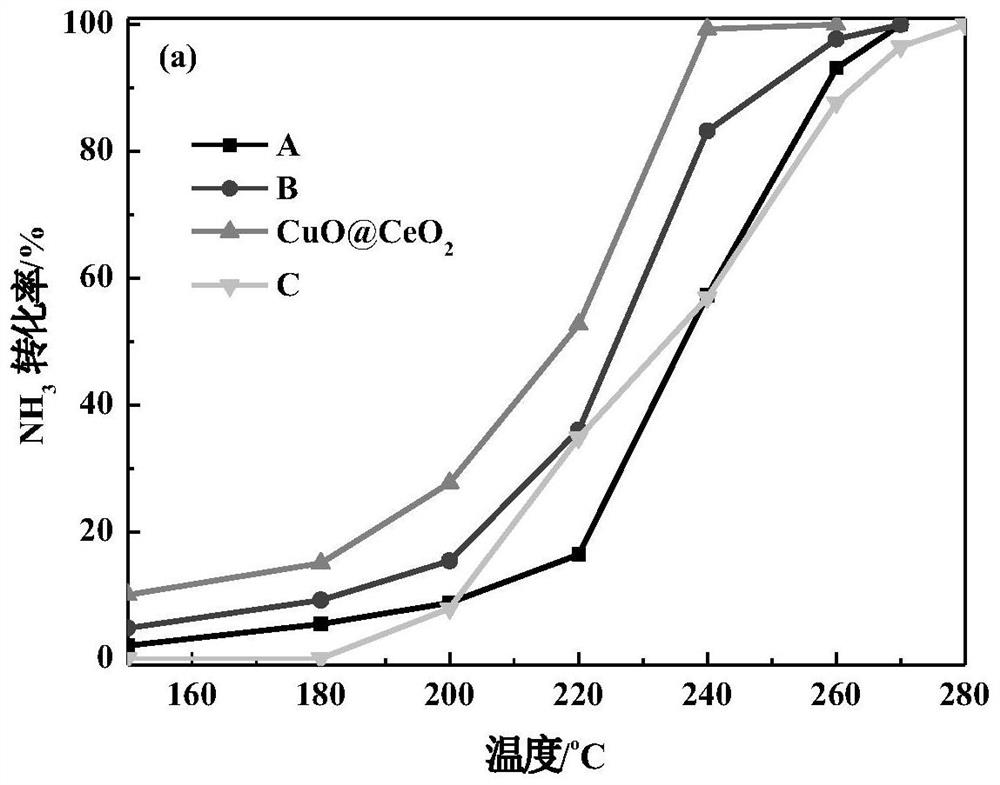

[0041] The catalyst NH prepared by embodiment 1 and comparative examples 1-3 3 Catalytic oxidation performance test is carried out in continuous operation on a fixed-bed reactor, He is used as balance gas, and NH 3 Analyzer and gas chromatograph on-line analysis of gaseous substance NH after reaction 3 Molecule and Product N 2 molecular. The specific reaction conditions are: 1000ppm NH 3 , 10vol%O 2 , He is used as the balance gas, and the reaction space velocity is 45000h -1 , the mass of the catalyst is 0.15g. Ammonia conversion rate as Figure 2a As shown, CuO@CeO 2 The catalytic activity is the best, reaching 100% NH at 240°C 3 conversion rate, while Figure 2b , N 2 The selectivity reaches more than 90% in the reaction temperature range.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com