Mn < 2 + >-doped cesium lead halogen group perovskite quantum dot film and preparation method thereof

A perovskite and quantum dot technology, applied in chemical instruments and methods, nanotechnology, coatings, etc., can solve the problems of poor product luminescence performance, material structure defects, strong annealing effect, etc., to increase the diffusion driving force, The effect of high crystal quality and high emission intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] a kind of Mn 2+ Doped cesium lead halide perovskite quantum dot thin film, its preparation method comprises the following steps:

[0047] 1) Mix OA, OAm, and an organic solvent uniformly at a volume ratio of (0.5-1.5):(0.05-0.2):10; wherein, the organic solvent can be N,N-dimethylformamide (DMF);

[0048] 2) Add CsX and PbY according to the molar ratio 1:1:(1-9) 2 、MnZ 2 (wherein the concentration of Mn is 0.04-0.31mol / L), after being fully reacted by magnetic stirring, it is left to stand for 30-60min to obtain a precursor solution; wherein, X, Y, and Z are at least one of Cl or Br respectively;

[0049] 3) mixing the precursor solution and toluene with a volume ratio of 1:(20-80) to obtain a perovskite quantum dot solution;

[0050] 4) Place the cleaned and dried flexible film substrate in the precursor solution, centrifuge at 2000-4000rpm for 5-10min, remove the supernatant and dry to obtain Mn 2+ Doped cesium lead halide perovskite quantum dot film; among them, ...

Embodiment 1

[0054] a kind of Mn 2+ Doped CsPbX 3 (X=Cl, Br) perovskite quantum dot film, its preparation method comprises the following steps:

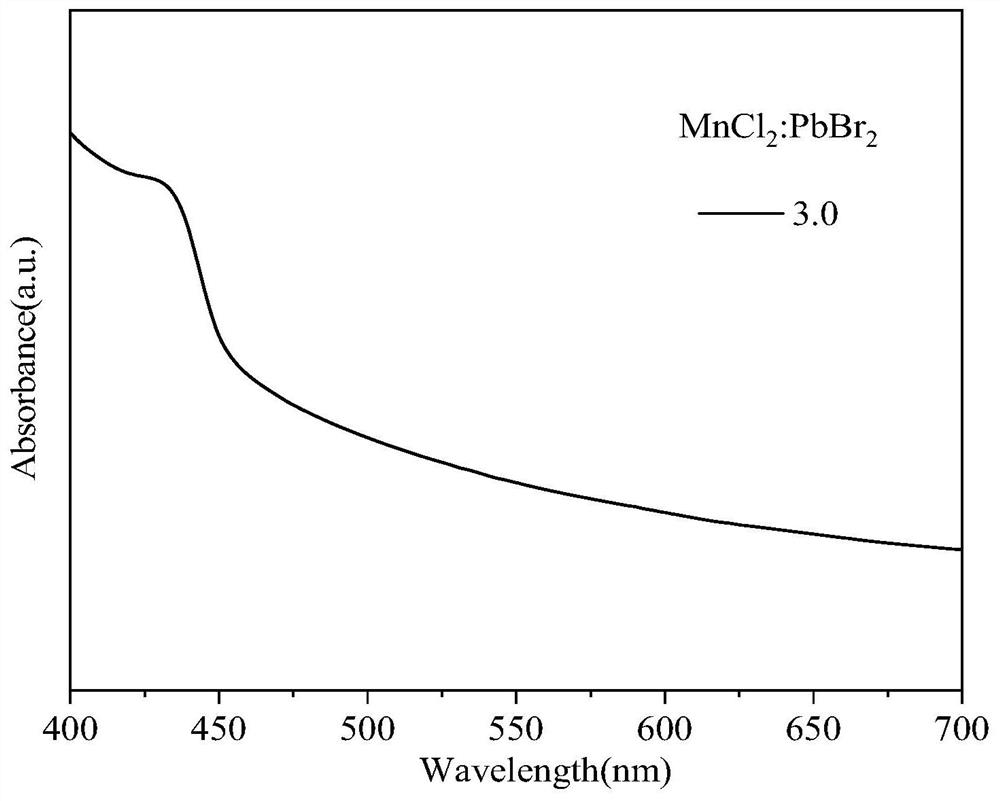

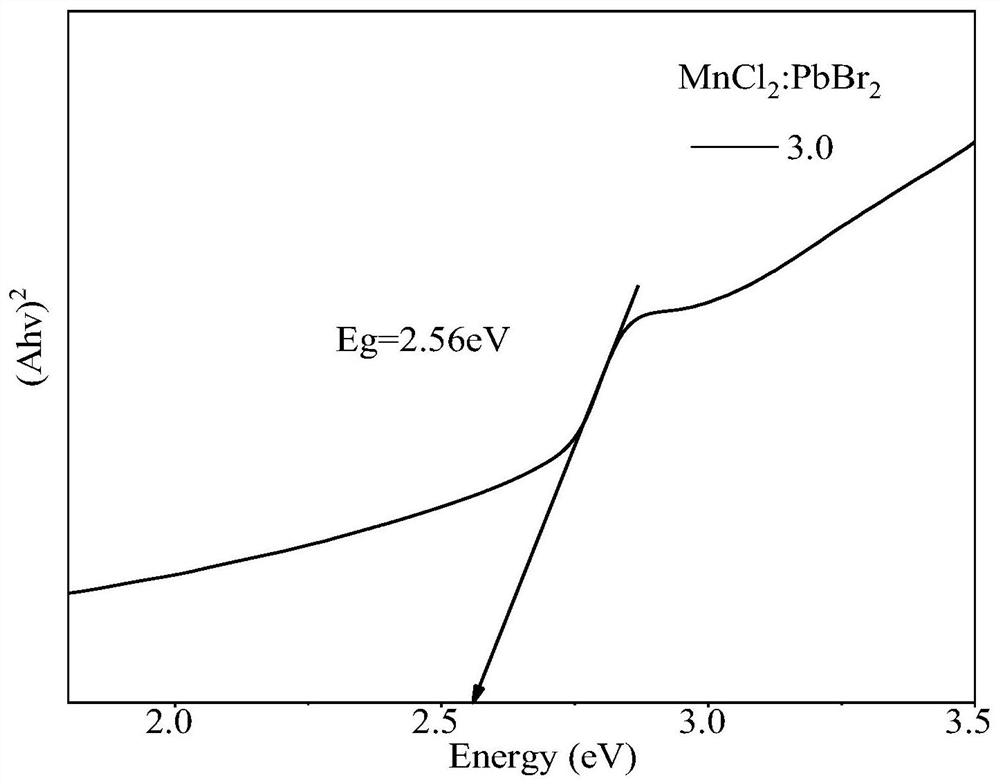

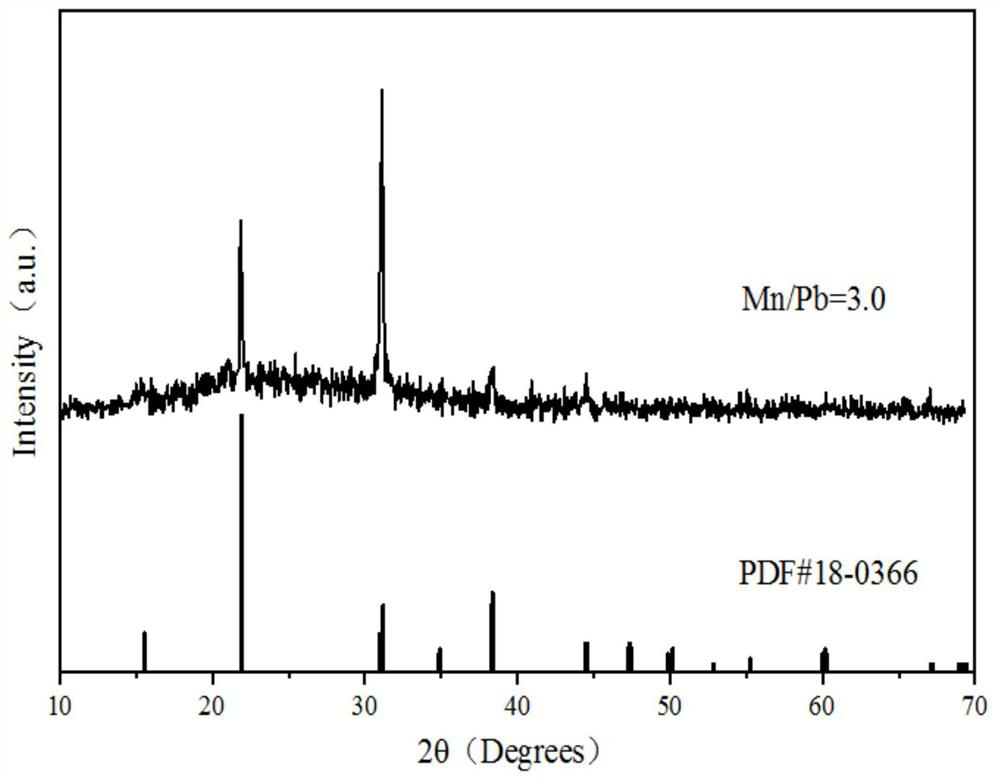

[0055] 1) Pipette 10mL DMF, 1mL OA, 0.2mL OAm into the beaker in sequence, then add 0.4mmol CsBr, 0.4mmol PbBr 2 , 1.2mmol MnCl 2 After mixing, it was fully reacted by magnetic stirring, and a mixed solution was obtained after standing for 30 minutes;

[0056] 2) Mix 1mL of the mixed solution with 0.04mmol of the silane coupling agent APTES to obtain a precursor solution;

[0057] 3) Take 100 μL of the precursor solution and add it dropwise to 5 mL of toluene to obtain Mn 2+ Doped CsPbX 3 (X=Cl, Br) perovskite quantum dot solution;

[0058] 4) After cleaning and drying the flexible film substrate, add to Mn 2+ Doped CsPbX 3 (X=Cl, Br) in the quantum dot solution, and then perform centrifugal coating at a centrifugal speed of 3000rpm for 5min, remove the supernatant, take out the product, and obtain Mn after drying. 2+ Doped CsPbX 3 (X=C...

Embodiment 2

[0065] a kind of Mn 2+ Doped CsPbX 3 (X=Cl, Br) perovskite quantum dot film, its preparation method comprises the following steps:

[0066]1) Use a pipette gun to pipette 10mL DMF, 1mL OA, 0.1mL OAm, and add them to the beaker in sequence, then add 0.5mmol CsCl, 0.5mmol PbBr 2 , 3.5mmol MnCl 2 After mixing, it was fully reacted by magnetic stirring, and a mixed solution was obtained after standing for 30 minutes;

[0067] 2) Mix 1 mL of the mixed solution with 0.06 mmol of silane coupling agent APTMS to obtain a precursor solution;

[0068] 3) Take 150 μL of precursor solution and add it dropwise into 5 mL of toluene to obtain Mn 2+ Doped CsPbX 3 (X=Cl, Br) perovskite quantum dot solution;

[0069] 4) After washing and drying the PET film substrate, add to Mn 2+ Doped CsPbX 3 (X=Cl, Br) in the quantum dot solution, and then perform centrifugal coating at a centrifugal speed of 3000rpm for 8min, remove the supernatant, take out the product, and obtain Mn after drying. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com