Method for preparing TiO2 molded catalyst carrier from titanium-based adhesive

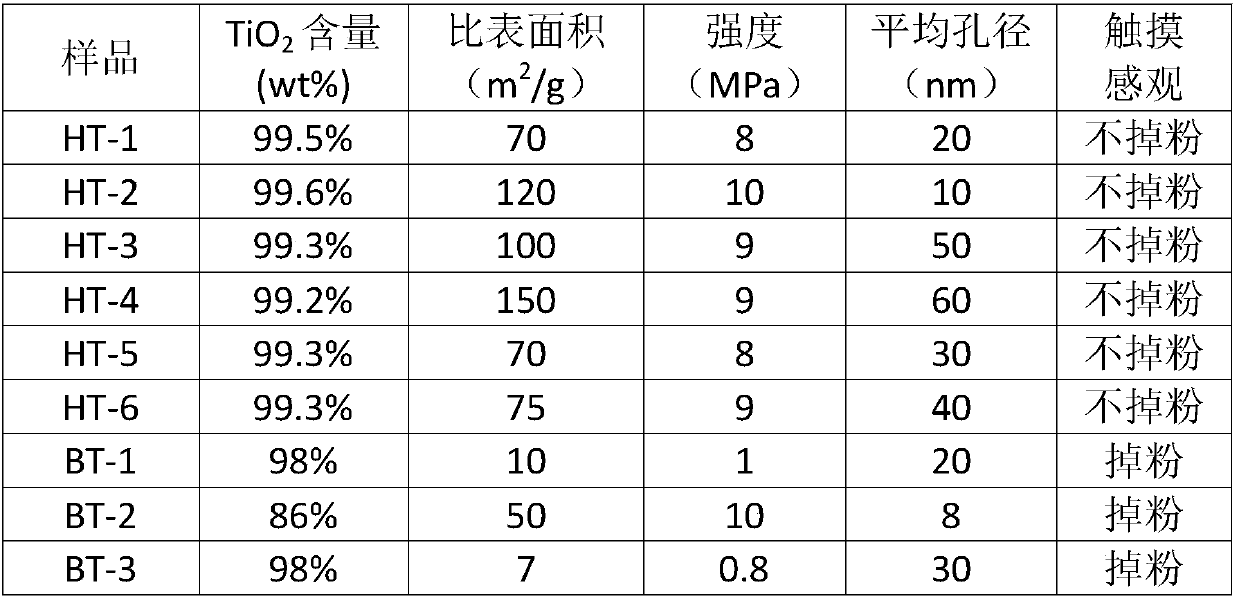

The technology of catalyst carrier and binder is applied in the field of preparation of catalyst shaped carrier, which can solve the problems of easy powder dropping, large specific surface area, low purity, etc., and achieve the effects of solving the pollution problem, improving the powder dropping problem and improving the strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Add 60g of titanyl sulfate into 600ml of water, and dissolve it at 80°C to obtain a clear and transparent solution. Add 340g of metatitanic acid to the solution, stir vigorously for 40 minutes, then transfer the mixture to a tetrafluoroethylene-lined hydrothermal reactor, and react at 120°C for 4 hours under autogenous pressure. Quench with water, cool down to room temperature with NH 3 ·H 2 Adjust the PH value of the mixed solution to about 7 and form a gel. The colloid is subjected to solid-liquid separation by suction filtration to obtain a colloidal filter cake, and the colloidal filter cake is washed repeatedly with deionized water until no sulfate ion is detected in the washing liquid. Place the washed colloidal filter cake in a microwave oven for heating and dehydration, adjust the microwave power to 800W, and heat for a total of 40 minutes, divided into 8 times, 5 minutes each time, with an interval of 3 minutes between adjacent two times, to obtain solid cont...

Embodiment 2

[0037] Add 70g of titanium tetrachloride to 400ml of water at room temperature, then add 360g of nano-TiO 2 , after vigorous stirring, the mixture was transferred to a tetrafluoroethylene-lined hydrothermal reactor and reacted at 150°C for 4 hours under autogenous pressure. Quench with water, cool down to room temperature with NH 3 ·H 2 Adjust the PH value of the mixed solution to about 5 and form a gel. The solid-liquid separation of the colloid is carried out by suction filtration to obtain a colloidal filter cake, and the colloidal filter cake is repeatedly washed with deionized water until chloride ions are detected in the washing liquid. Place the washed colloidal filter cake in a microwave oven for heating and dehydration, adjust the microwave power to 800W, and heat for a total of 40 minutes, divided into 8 times, 5 minutes each time, with an interval of 3 minutes between adjacent two times, to obtain solid content A cement-like dough with a rate of 70%. The clay-li...

Embodiment 3

[0039] Add 30g of titanyl sulfate into 300ml of water, and dissolve it at 80°C to obtain a clear and transparent solution. Add 370g nano TiO to the solution 2 After stirring vigorously for 40 minutes, the mixture was transferred to a tetrafluoroethylene-lined hydrothermal reactor and reacted at 180°C for 4 hours under autogenous pressure. Quench with water, cool down to room temperature with NH 3 ·H 2 Adjust the PH value of the mixed solution to about 3 and form a gel. The colloid is subjected to solid-liquid separation by suction filtration to obtain a colloidal filter cake, and the colloidal filter cake is washed repeatedly with deionized water until no sulfate ion is detected in the washing liquid. Place the washed colloidal filter cake in a microwave oven for heating and dehydration, adjust the microwave power to 800W, and heat for a total of 40 minutes, divided into 8 times, 5 minutes each time, with an interval of 3 minutes between adjacent two times, to obtain solid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com