Hole array steel surface composite coating and preparation method thereof

A technology of surface compounding and hole array, which is applied in the coating, metal material coating process, etc., can solve the problems of low coating structure hardness, high wear, and large friction coefficient, so as to optimize the coating structure and prolong the service life , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a method for preparing a composite coating on a steel surface with a hole array, which comprises the following steps:

[0030] Process the steel surface to obtain surface steel holes arranged in parallel in a lattice;

[0031] Combine Ti powder, Cr powder, Al powder and Cr 3 C 2 After the powder is mixed, sintered to obtain (Ti x ,Cr 1-x ) 3 AlC 2 Solid solution composite powder;

[0032] Put the (Ti x ,Cr 1-x ) 3 AlC 2 The solid solution composite powder is etched with an etching solution to obtain (Ti x ,Cr 1-x ) 3 C 2 Powder

[0033] After mixing Ti powder and Si powder, sintering to obtain Ti-Si pre-alloy powder;

[0034] Will Ni 9 Cr 5 Al 5 Mo powder, (Ti x ,Cr 1-x ) 3 C 2 Powder, Ni powder coated MoS 2 Mixing the powder with the Ti-Si pre-alloy powder and B powder to obtain a mixed powder;

[0035] The mixed powder is pre-placed on the surface steel hole with an adhesive, and laser cladding and heat treatment are sequentially performed to obtain a comp...

Embodiment 1

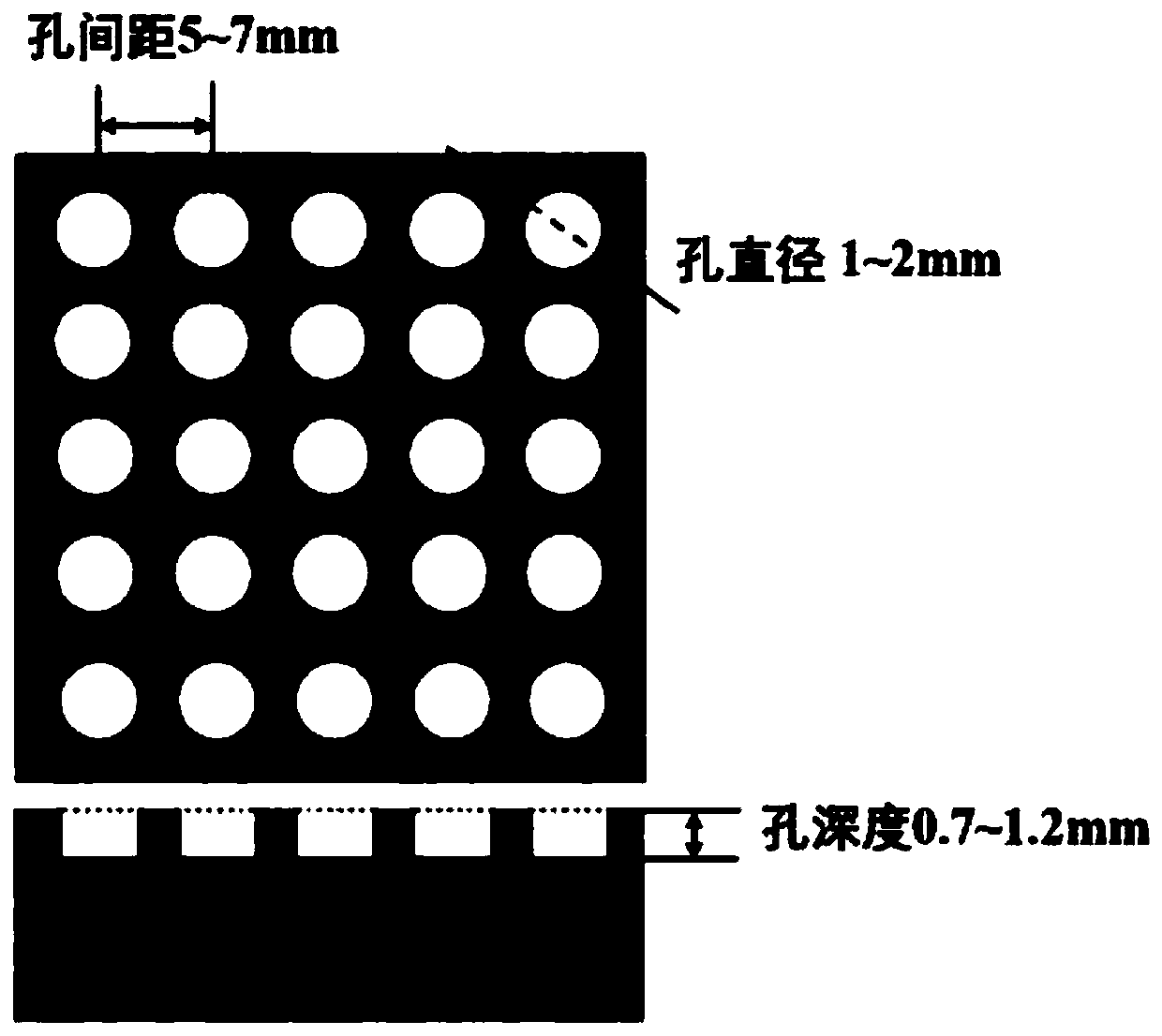

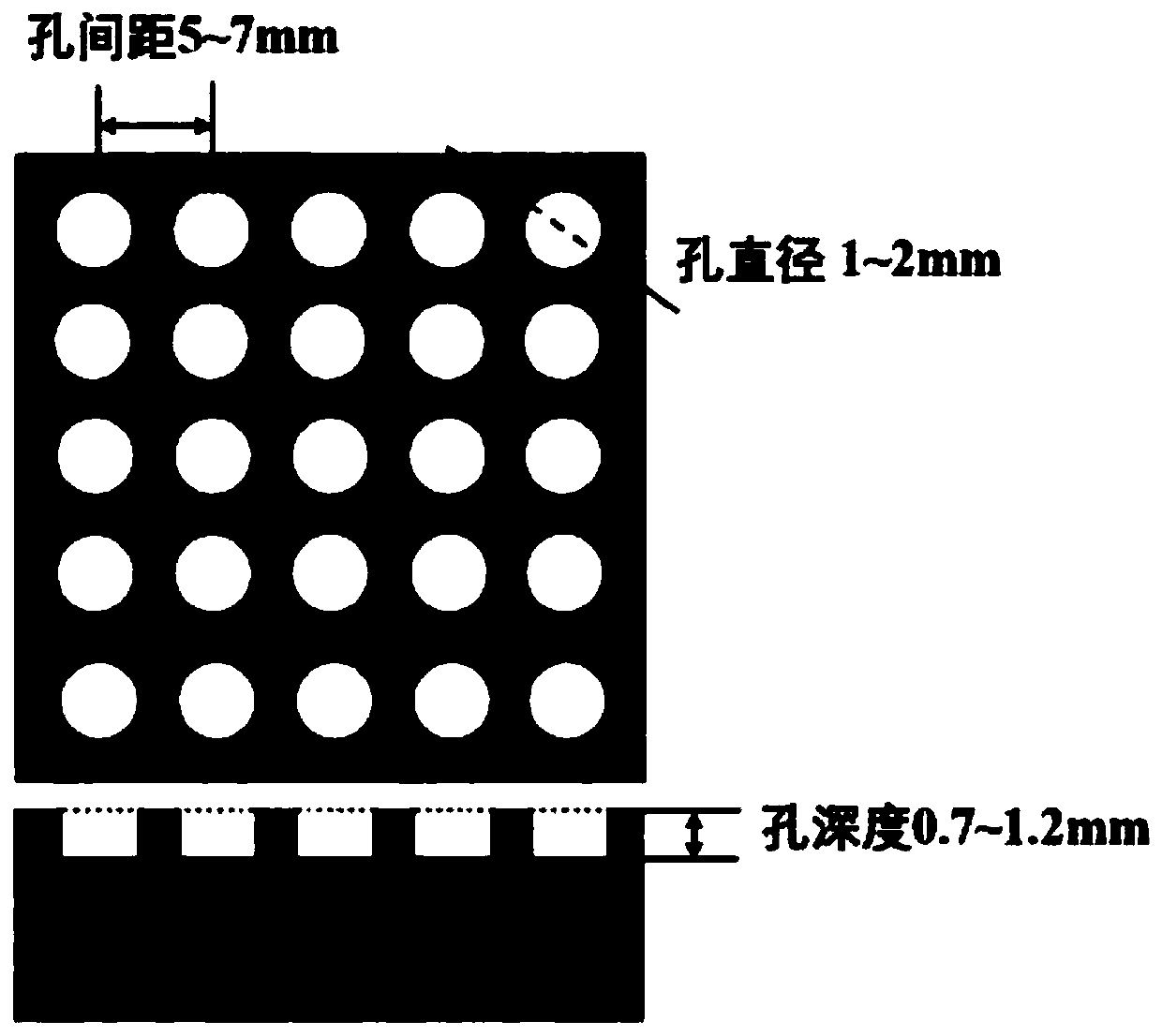

[0074] press figure 1 As shown, the Q235 low-carbon steel surface line is cut into a sample with a size of 80mm×80mm×10mm, and then the surface steel holes with circular holes arranged in parallel in a lattice are processed. The diameter of the circular holes is 1.5mm, the depth is 0.9mm, and two The distance between the center of the hole is 6mm, the surface is polished to remove the surface oxide film, and cleaned with ethanol;

[0075] By atomic ratio (Ti 0.65 ,Cr 0.35 ) 3 AlC 2 Calculate and weigh Ti powder, Cr powder, Al powder, Cr 3 C 2 Powder, dry ball milling and mixing for 2 hours, the ball mill equipment is a planetary ball mill, the ball mill spindle speed is 350r / min, the filling factor is 0.4, the ball abrasive is agate balls, the ball mill tank is a nylon ball mill tank, protected by argon gas, and then the ball is ground. The powder is put into a graphite crucible covered with graphite paper and sintered in a vacuum furnace at 1380℃ for 2 hours to obtain (Ti 0.65 ,C...

Embodiment 2

[0083] press figure 1 As shown, the Q235 low-carbon steel surface line is cut into a sample with a size of 80mm×80mm×10mm, and then the surface steel holes with circular holes arranged in parallel in a lattice are processed. The diameter of the circular holes is 1.0mm, and the depth is 0.7mm. The distance between the center of the hole is 5mm, the surface is polished to remove the surface oxide film, and cleaned with ethanol;

[0084] By atomic ratio (Ti 0.5 ,Cr 0.5 ) 3 AlC 2 Calculate and weigh Ti powder, Cr powder, Al powder, Cr 3 C 2 Powder, dry ball milling and mixing for 0.5h, the ball mill equipment is a planetary ball mill, the ball mill spindle speed is 4500r / min, the filling factor is 0.4, the ball abrasive is agate balls, the ball mill tank is a nylon ball mill tank, protected by argon gas, and then the ball is ground. The powder is put into a graphite crucible covered with graphite paper and sintered in a vacuum furnace at 1350℃ for 3 hours to obtain (Ti 0.5 ,Cr 0.5 ) 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com