A kind of weaving fiber composite plate based on nano-ceramic material and its preparation method

A technology of fiber composite and nano-ceramics, which is applied in clay products, other household utensils, household utensils, etc., can solve the problems of difficult composite, destruction of fiber-reinforced phase structure, high melting point of ceramics, etc., and achieve good high-temperature performance, high specific strength, The effect of low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

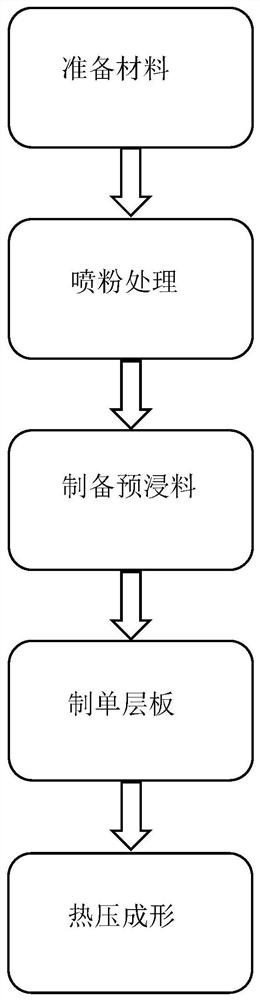

[0026] Such as figure 1 Shown, the present invention proposes a kind of preparation method based on the weaving fiber composite plate of nano-ceramic material, and this method comprises the steps:

[0027] (a) Evenly spray nano-ceramic powder with a particle size of preferably 1 nm to 1000 nm on both sides of the weaving fiber cloth with a neat weaving direction. Heating at a temperature of ℃~200℃ and keeping it warm for 5min~10min, so that the nano-ceramic powder is pre-impregnated into the woven fiber cloth to obtain a prepreg;

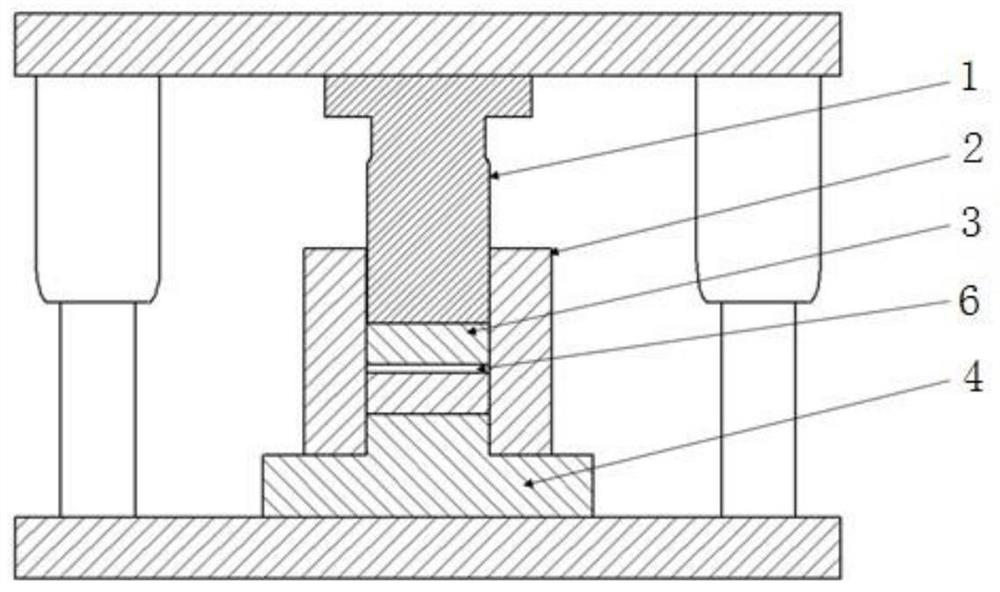

[0028] (b) Cut the cooled prepreg according to the specified specifications to obtain a single-layer composite board, and then put 5 to 10 single-layer composite boards into the mold, at 0°C to 100°C higher than the melting point of the nano-ceramic powder Or heat at a temperature lower than the melting point of the nano-ceramic powder at 0°C to 100°C, and apply a pressure of 1MPa to 500MPa, and keep for 5min to 200min to completely bond the compos...

Embodiment 1

[0035] (a) Evenly spray the nano-ceramic powder whose particle size is preferably 1nm on both sides of the weaving fiber cloth with neat weaving direction, then heat and keep warm for 10 minutes at a temperature lower than the melting point of the nano-ceramic powder at 200°C to make the nano-ceramic The powder is pre-impregnated into the woven fiber cloth to obtain the prepreg;

[0036] (b) Cut the cooled prepreg according to the specified specifications to obtain a single-layer composite plate, then put 10 single-layer composite plates into the mold, heat at a temperature 100°C higher than the melting point of the nano-ceramic powder, and Pressurize at 1MPa and keep for 200min to make the composite board fully bonded;

[0037] (c) Finally stop heating and slowly release the pressure, and open the mold after cooling to room temperature to obtain the woven fiber composite board.

Embodiment 2

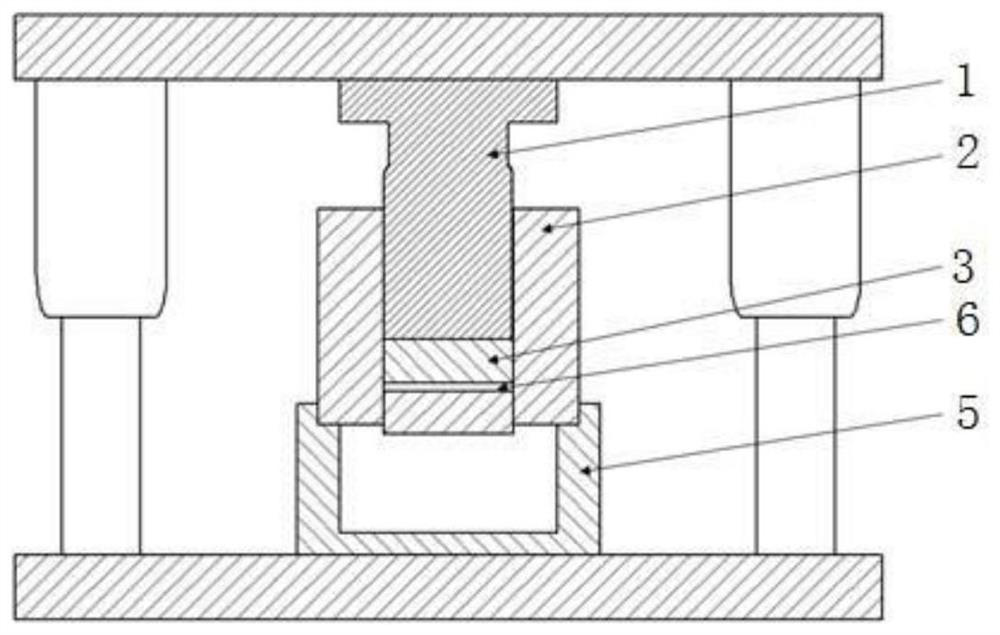

[0039] (a) Evenly spray the nano-ceramic powder whose particle size is preferably 1000nm on both sides of the weaving fiber cloth with neat weaving direction, then heat and keep warm at the melting point temperature of the nano-ceramic powder for 5 minutes, so that the nano-ceramic powder is pre-impregnated into the weaving Obtain prepreg from fiber cloth;

[0040] (b) Cut the cooled prepreg according to the specified specifications to obtain a single-layer composite plate, then put 8 single-layer composite plates into the mold, heat at a temperature higher than the melting point of the nano-ceramic powder at 55°C, and Pressurize at 60MPa and keep for 5min to fully combine the composite panels;

[0041] (c) Finally stop heating and slowly release the pressure, and open the mold after cooling to room temperature to obtain the woven fiber composite board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com