Dynamic ion cross-linked polyacrylic acid-polyethylene glycol hydrogel binding agent and preparation method and application thereof

A hydrogel adhesive, polyethylene glycol technology, applied in the direction of secondary batteries, structural parts, electrochemical generators, etc., can solve the problems of conductive network rupture, active material loss, weak van der Waals force, etc., to maintain Stability, strong mechanical strength and tensile strength, stress relief effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention discloses a dynamically ionically cross-linked polyacrylic acid-polyethylene glycol hydrogel adhesive and its preparation method and application; the preparation of the material specifically includes the following steps:

[0029] Step 1, prepare PEG aqueous solution, add polyethylene glycol (PEG) with a weight average molecular weight of 400-20000 into deionized water, stir to dissolve completely, and obtain a PEG aqueous solution with a mass concentration of 5-10%, marked as A solution.

[0030] Step 2, synthesizing the acrylic acid prepolymer, adding the acrylic acid monomer into deionized water to obtain an acrylic acid aqueous solution with a mass concentration of 10-25%, adding a redox initiator, which is a type of initiator that is easily decomposed into free The base compound is one or both of sodium metabisulfite or ammonium persulfate, and when the initiator is a mixture of the two, it is an initiator mixed in equimolar amounts; the amount of the ...

Embodiment 1

[0043] Dissolve PEG and acrylic acid monomers with Mw=400 in deionized water, respectively configure aqueous solutions with a mass fraction of 5% and 15%, add an initiator of 0.1 wt% of acrylic acid monomer mass in the aqueous acrylic acid solution, and the initiator is sodium metabisulfite ;Raise the temperature of the acrylic acid aqueous solution containing the initiator to 90°C, add the PEG aqueous solution dropwise to the acrylic acid aqueous solution containing the initiator according to the mass ratio of 1:9, stir and mix evenly, and the reaction occurs. When the reaction system is viscous, the reaction ends Finally, a hydrogel polymer with a stable three-dimensional network structure is formed, and 10% NaOH aqueous solution is added to the polymer to obtain the adhesive A1.

[0044] The binder A1 that prepares is used in ion secondary battery, and the preparation process of this battery comprises the following steps:

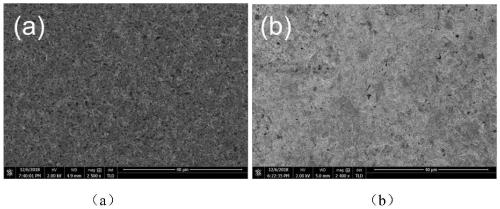

[0045] Step 1, prepare micron silicon, carbon blac...

Embodiment 2

[0052] PEG and acrylic acid monomers with Mw=800 were dissolved in deionized water, and aqueous solutions with mass fractions of 10% and 15% were prepared respectively, and an initiator of 1 wt% of acrylic acid monomer mass was added to the aqueous acrylic acid solution, and the initiator was sodium metabisulfite; Raise the temperature of the acrylic acid aqueous solution containing the initiator to 80°C, add the PEG aqueous solution dropwise to the acrylic acid aqueous solution containing the initiator according to the mass ratio of 3:7, stir and mix evenly, and the reaction occurs. After the reaction, water with a stable three-dimensional network structure is generated. Gel polymer, adding 20% NaOH aqueous solution to the polymer, namely to prepare adhesive A2.

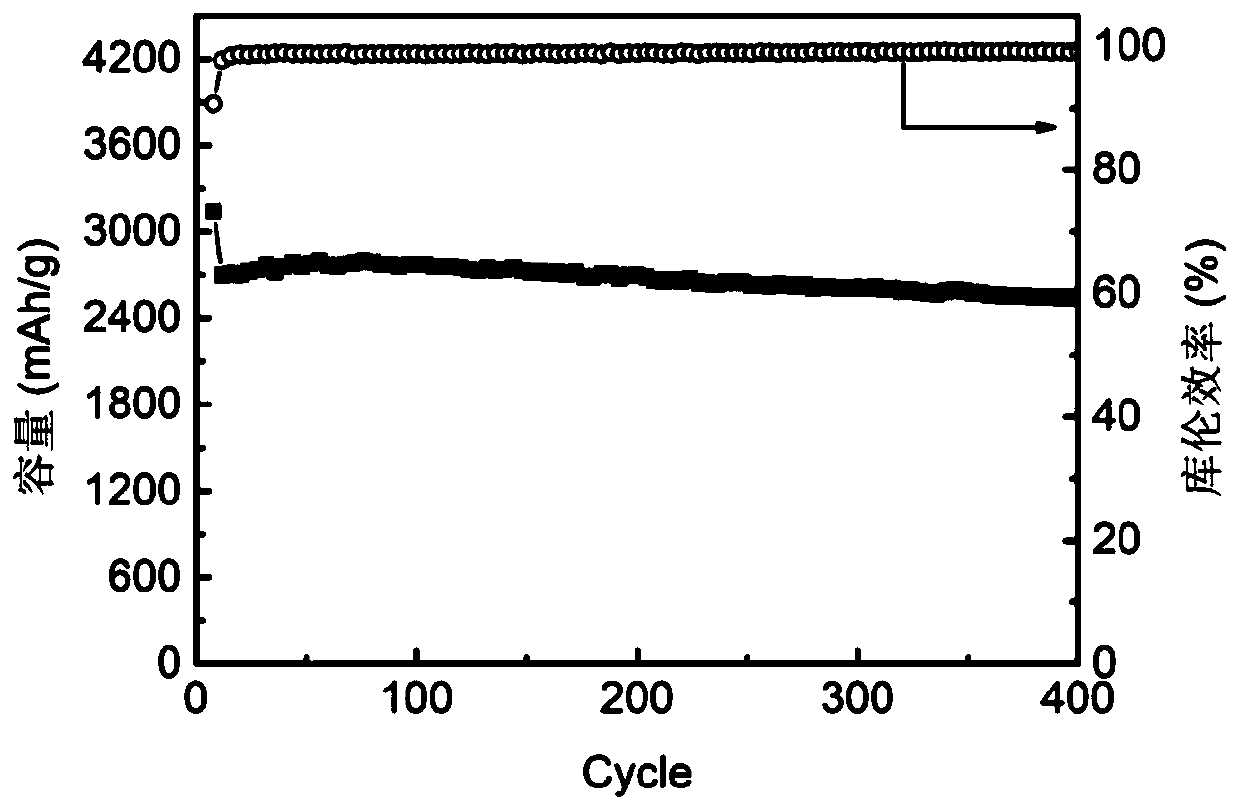

[0053] A lithium-ion battery was assembled according to the above method using binder A2 and its electrochemical performance was tested.

[0054] The prepared binder A2 was used in the preparation of an ion second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com