A method for preparing yttrium zirconate nanofibers from a zirconium-yttrium polymer precursor

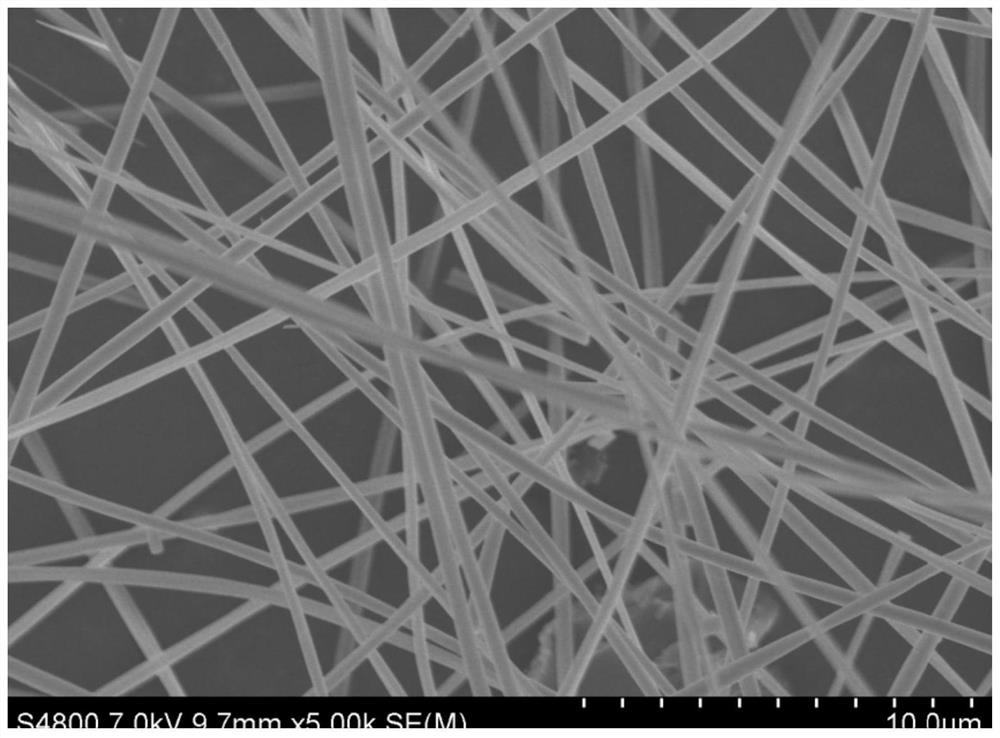

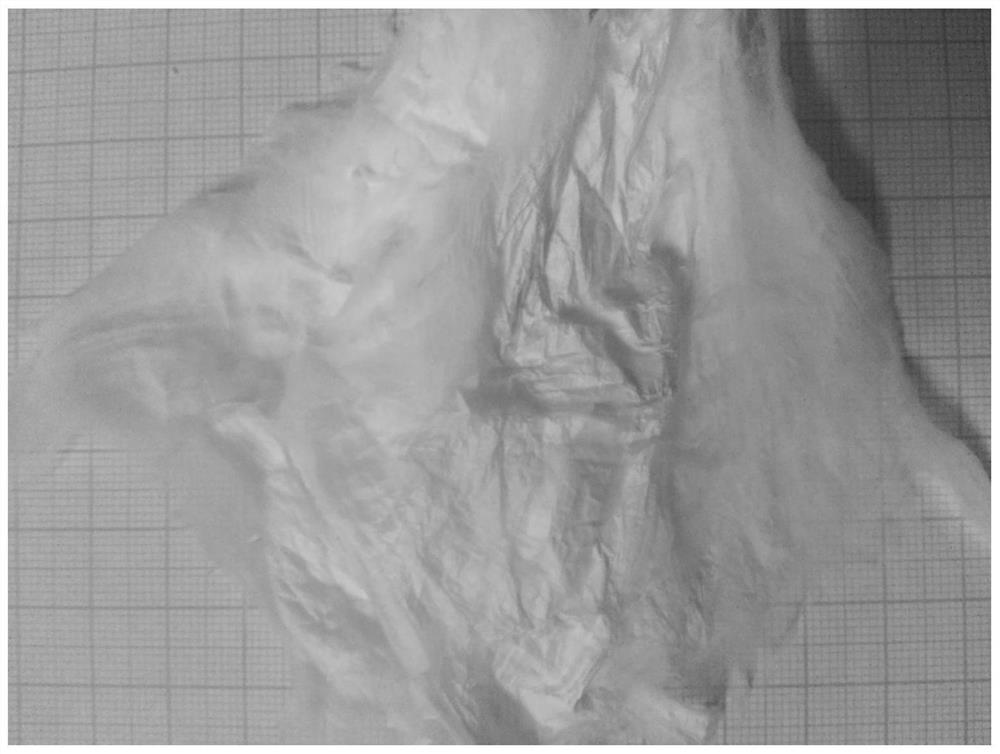

A nanofiber and polymer technology, applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of difficult to achieve nanofiber preparation, high solid-phase reaction temperature, and inability to obtain precursors, and achieve easy mass production, The effect of uniform fiber diameter and dense structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of zirconium-yttrium polymer is the method that precursor prepares yttrium zirconate fiber, comprises the following preparation steps:

[0032] (1) Dissolve 1mol zirconium oxychloride octahydrate and 1mol yttrium chloride hexahydrate in 2000g of anhydrous methanol, add 210g acetylacetone and 500g triethylamine successively after dissolving completely (zirconium oxychloride octahydrate: acetylacetone : the mol ratio of triethylamine is 1:2.1:4.9), obtains yellow solution after stirring 5h;

[0033] (2) Transfer the yellow solution obtained in step (1) to a round-bottomed flask and concentrate and dry under reduced pressure at 40° C. to obtain a zirconium-yttrium polymer precursor containing triethylamine hydrochloride;

[0034] (3) Soak the zirconium-yttrium polymer precursor containing triethylamine hydrochloride obtained in step (2) with 4000mL acetone, and let it stand at room temperature for 72h, then filter out triethylamine hydrochloride to obtain zirconium-...

Embodiment 2

[0040] As described in Example 1, the difference is:

[0041] In step (1), 1mol zirconium oxychloride octahydrate and 1mol yttrium chloride hexahydrate are dissolved in 2000g anhydrous methanol, add 150g acetylacetone and 435g triethylamine (zirconium oxychloride octahydrate: Acetylacetone: the molar ratio of triethylamine is 1:1.5:4.3), after stirring for 5h, a yellow solution was obtained.

Embodiment 3

[0043] As described in Example 1, the difference is:

[0044] In step (1), 1mol zirconium oxychloride octahydrate and 1mol yttrium chloride hexahydrate are dissolved in 2000g anhydrous methanol, after dissolving completely, add 300g acetylacetone and 607g triethylamine successively respectively (zirconium oxychloride octahydrate: Acetylacetone: the molar ratio of triethylamine is 1:3:6), after stirring for 5h, a yellow solution was obtained.

[0045] Example 3

[0046] As described in Example 1, the difference is:

[0047] As described in step (3), soak the zirconium-yttrium polymer precursor containing triethylamine hydrochloride obtained in step (2) with 4000mL acetone, and leave it at room temperature for 48h, then filter out triethylamine hydrochloride to obtain zirconium - A solution of yttrium polymer precursor in acetone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com