High-performance lithium nickel cobalt aluminum oxide positive material and preparation method thereof

A technology of nickel cobalt lithium aluminate and cathode material, applied in chemical instruments and methods, battery electrodes, nickel compounds, etc., can solve problems such as failure to improve cycle, failure to completely solve the basic problem of grain boundaries between primary particles, etc. Improve cycle performance, good surface reactivity, good sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the high-performance nickel-cobalt lithium aluminate cathode material of the present invention comprises the following steps:

[0034] 1) According to the chemical formula Ni 1-x-y co x al y o 2 The stoichiometric ratio of (0<x≤0.2, 0<y≤0.05) configures the soluble salt solution of nickel-cobalt-aluminum to obtain solution I;

[0035] 2) Prepare precipitant solution II;

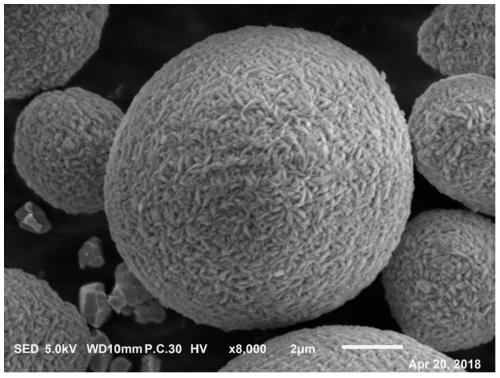

[0036]3) Add deionized water and ammonia water to the reaction kettle to make the pH value in the reaction kettle between 10.5 and 11.0, then disperse polystyrene microspheres PSt into the reaction vessel, add trimethylhexadecyl bromide Ammonium is used as a surfactant; then use a metering pump to pump in solutions I, II and complexing agent solutions, and under stirring, control the reaction temperature at 50°C to 80°C and the pH value at 10.5 to 12.5. After the pH of the reaction system is stable, continue React for 6-12 hours, use polystyrene microspheres PSt as seeds,...

Embodiment 1

[0053] 1) Weigh 100g of nickel chloride, 18.76g of cobalt chloride, and 3.51g of aluminum chloride according to the molar ratio Ni / Co / Al=80:15:5, and dissolve the nickel chloride, cobalt chloride, and aluminum chloride Prepare a 2mol / L mixed solution in deionized water;

[0054] 2) Take a crystallized beaker and add 1.75m styrene, 0.2g divinylbenzene and 40mg azobisisobutyronitrile, mix well, then add the pre-configured dispersion medium (3% polyvinyl alcohol solution by volume ), ultrasound for 20min. Then transfer the uniformly mixed emulsion to a three-necked flask, place it on a constant temperature water bath, and stir continuously at a speed of 200r / min at 2°C for 1h, then raise the temperature to 80°C, and react for 2h; Separation with a centrifuge, repeated washing with deionized water and 95% ethanol, and finally drying the washed PSt microspheres in a vacuum oven at 60°C for 12 hours, D 50 = 100 nm polystyrene microspheres.

[0055] 3) The prepared D 50 =100nm 0....

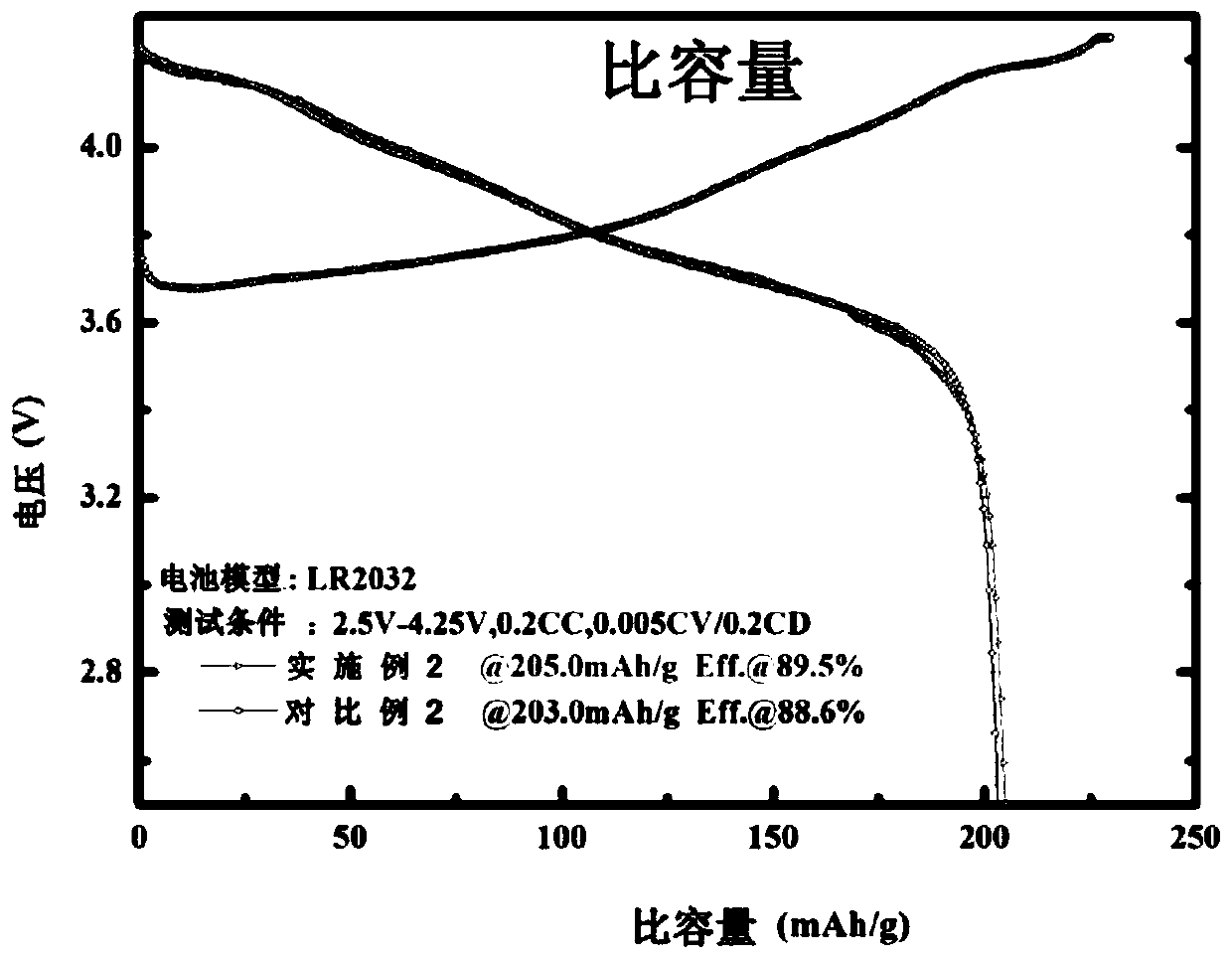

Embodiment 2

[0058] 1) Weigh 150g of nickel sulfate, 28.76g of cobalt sulfate, and 3.51g of aluminum sulfate according to the molar ratio Ni / Co / Al=88:9:3, and dissolve nickel sulfate, cobalt sulfate, and aluminum sulfate in deionized water to prepare 2.3mol / L mixed solution;

[0059] 2) Take a crystallized beaker and add 1.75m styrene, 0.2g divinylbenzene and 40mg azobisisobutyronitrile, mix well, then add the pre-configured dispersion medium (3% polyvinyl alcohol solution by volume ), ultrasound for 20min. Then transfer the uniformly mixed emulsion to a three-necked flask, place it on a constant temperature water bath, and stir continuously at a speed of 200r / min at 2°C for 1h, then raise the temperature to 80°C, and react for 2h; Separation with a centrifuge, repeated washing with deionized water and 95% ethanol, and finally drying the washed PSt microspheres in a vacuum oven at 60°C for 12 hours, D 50 =150nm polystyrene microspheres.

[0060] 3) The prepared D 50 =150nm 0.5g of poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com