Building structural foundation with three-dimensional shock insulation and vibration attenuation

A technology for seismic isolation and vibration reduction and building structure, which is applied to building components, buildings, building types, etc., can solve the problems of violent fluctuation of friction coefficient, no vibration reduction effect, and lack of vibration reduction protection effect of upper structure, and achieves reliability in use. The effect of improved, superior damping and vibration reduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

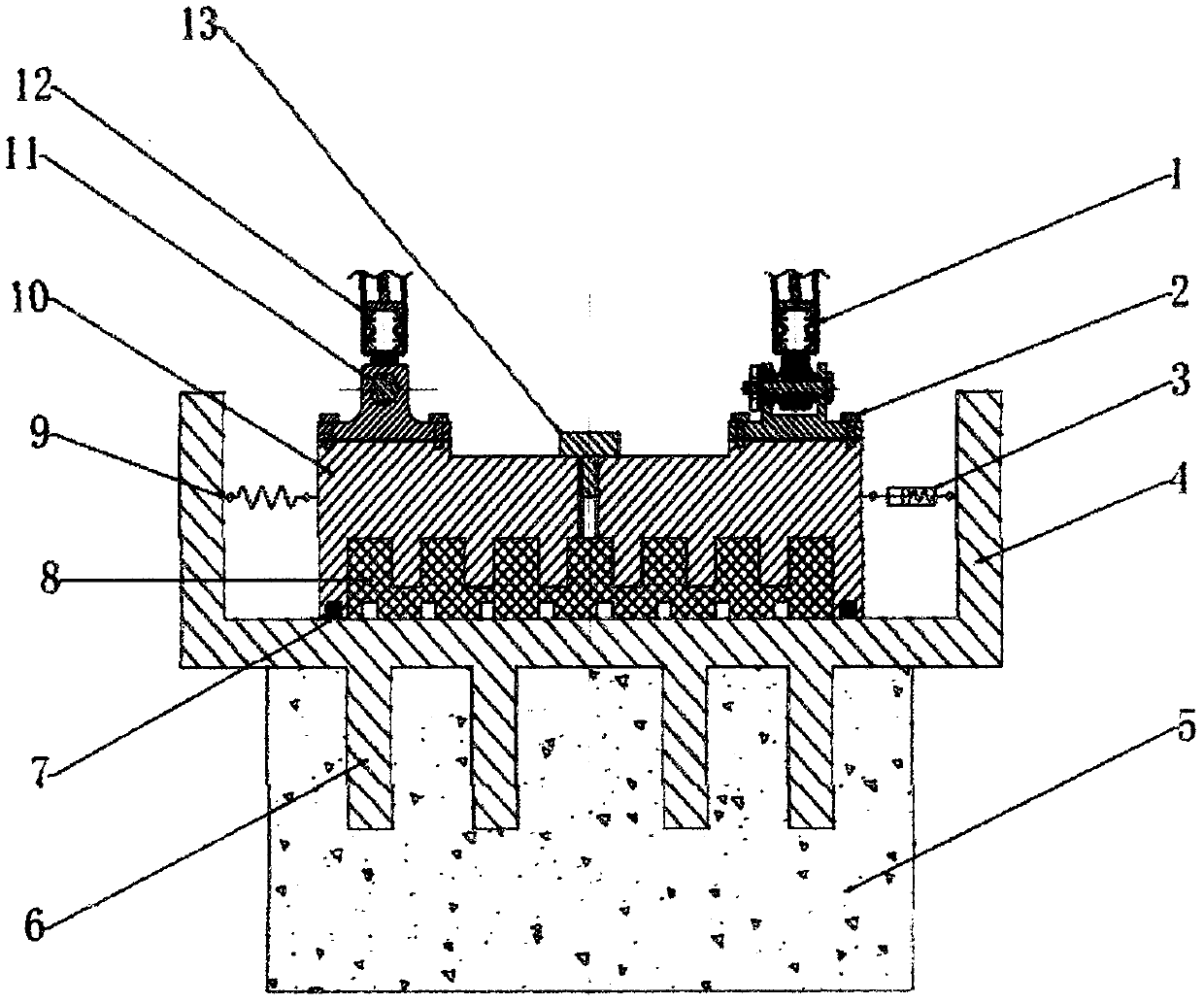

[0024]Embodiment, a building structure foundation with three-dimensional shock isolation and vibration reduction, including: a steel structure small platform (1) firmly connected with a reinforced concrete pile foundation and rooted in the foundation, and the flat sliding support surface on the small platform is prepared after sand blasting There is a polytetrafluoroethylene-based coating (Teflon coating) with a thickness of 0.30-0.35 mm as the material of the sliding friction pair with a low friction coefficient; the sliding table (2) for the shock absorber is installed with high-density polyethylene / paraffin oil as the main body Oil-containing self-lubricating composite materials, wherein: the weight average molecular weight of high-density polyethylene (HDPE) is between 600,000 and 800,000, and the weight percentage of high-density polyethylene (HDPE) in the composite material is 29%, and ethylene-vinyl acetate copolymer (EVA) accounts for 13% by weight of the composite mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com