Continuous treatment device for high-salinity high-COD chemical hazardous waste

A chemical and hazardous waste technology, applied in the field of devices for continuous treatment of high-salt and high-COD chemical hazardous wastes, can solve the problems of equipment corrosion, large land occupation, reduced thermal efficiency, etc., and achieve the effect of complete reaction and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

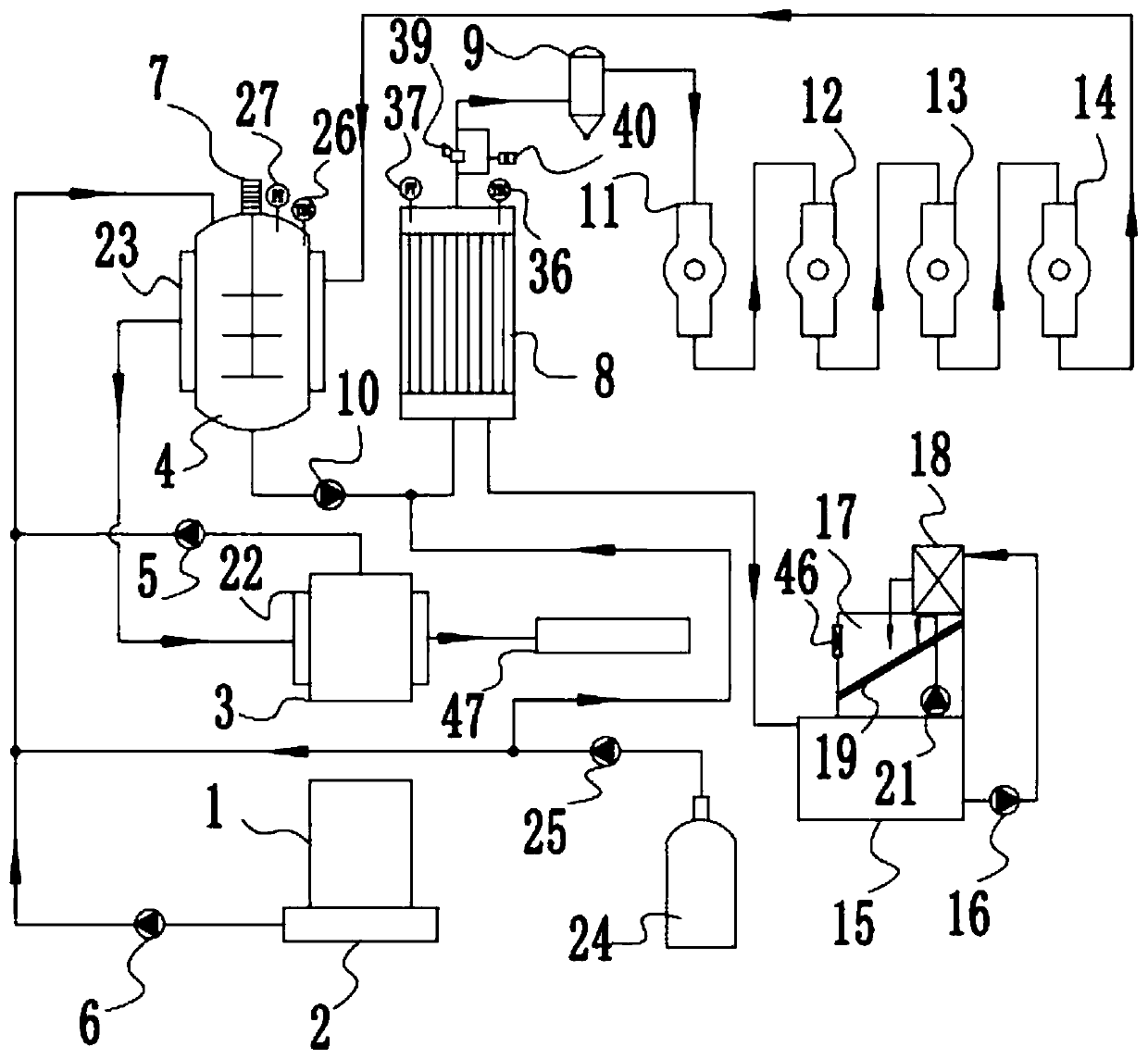

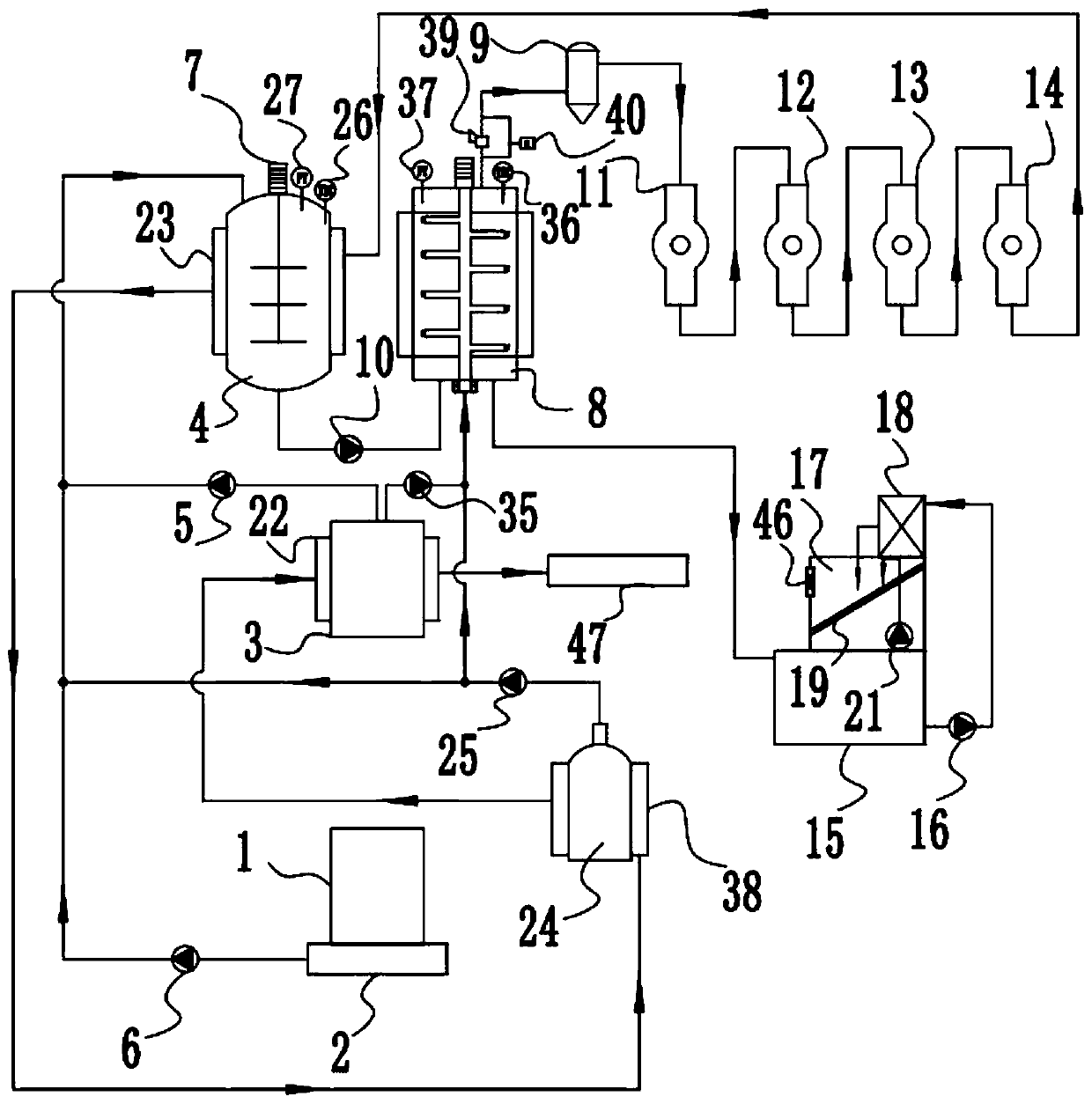

[0038] Such as figure 1 As shown, a device for continuous treatment of high-salt and high-COD chemical hazardous waste, including a pretreatment system, a hydrothermolysis system, a catalytic reforming system, a high-concentration brine evaporation and salt separation system, a heating system, an auxiliary system, and comprehensive utilization of methane systems and power supplies,

[0039] The pretreatment system includes a material storage tank 1, a metering device 2, a water tank 3, a pretreatment mixing device 4, a high-pressure water pump 5, and a material feed pump 6. The material storage tank 1 is connected to the metering device 2, and the metering device 2 is connected to the material pump 6. To the pretreatment mixing device 4, the water tank 3 is connected to the pretreatment mixing device 4 through the high pressure water pump 5, and the pretreatment mixing device 4 is provided with an agitator 7;

[0040] The hydrothermolysis system comprises a hydrothermolysis r...

Embodiment 2

[0054] This embodiment is basically the same as Embodiment 1, the difference is:

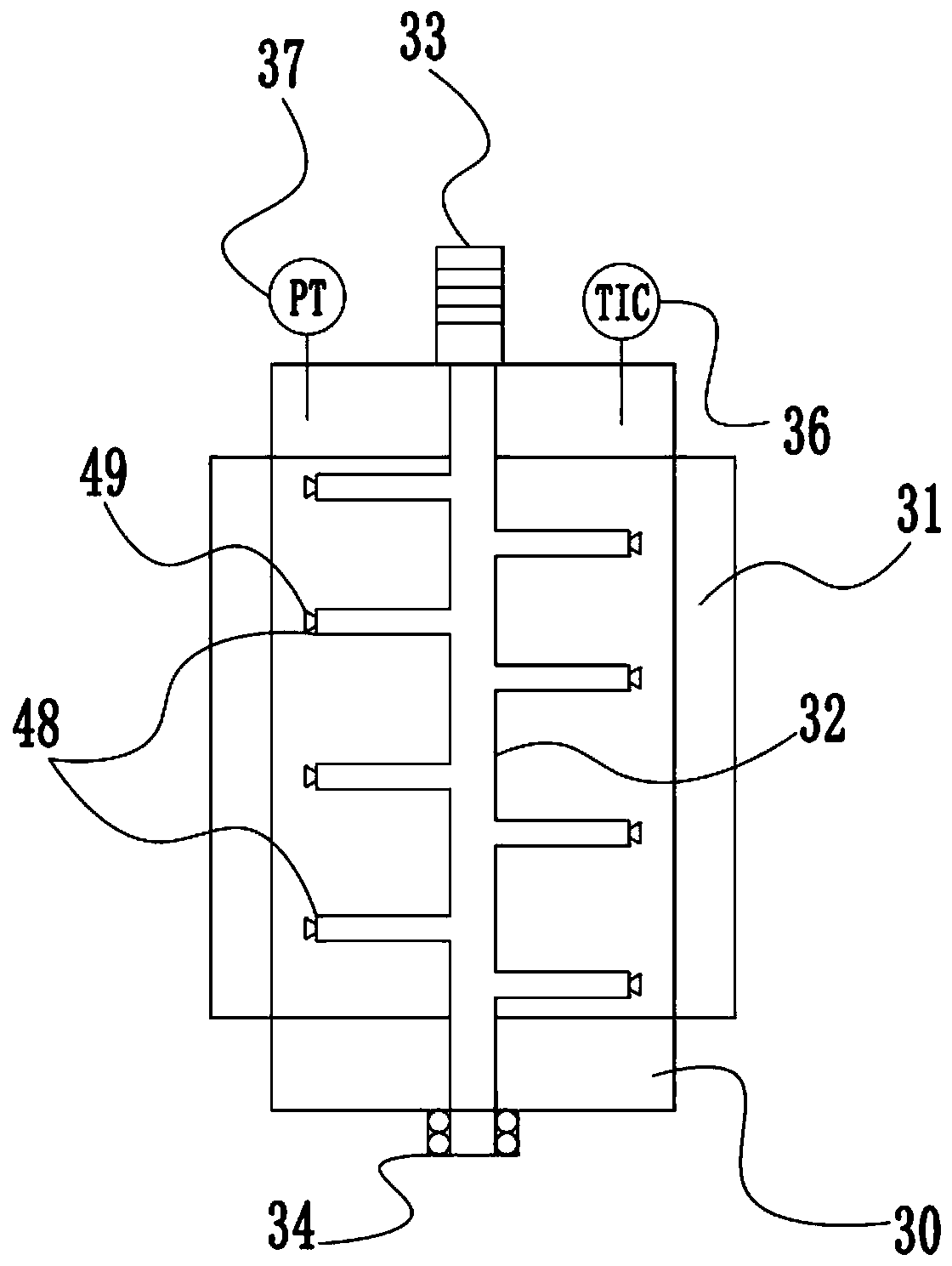

[0055] (1) if image 3 As shown, the hydrothermolysis reactor 8 includes a reaction tank 30, a tubular heat exchange jacket 31, an aeration stirring rod 32, a stirring motor 33, and a sealed bearing 34. The tubular heat exchange jacket 31 is arranged on the reaction tank 30 outside, the stirring motor 33 is arranged on the top of the reaction tank 30, the sealed bearing 34 is arranged on the bottom of the reaction tank 30, the interior of the aeration stirring rod 32 is hollow, and the aeration stirring rod 32 is horizontally provided with 8 stirring bars 48, stirring The far end of the crossbar 48 is provided with an aeration nozzle 49, the upper end of the aeration stirring rod 32 runs through the top of the reaction tank 30 and is connected with the stirring motor 33, and the lower end of the aeration stirring rod 32 runs through the bottom of the reaction tank 30 and is connected with the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com