3D lithium metal negative electrode, lithium metal battery and preparation and application thereof

A technology for lithium metal batteries and metal lithium layers, which is applied in electrode manufacturing, battery electrodes, lithium storage batteries, etc., can solve the problems that lithium metal negative electrodes are difficult to be practical, achieve uniform lithium nucleation and deposition sites, and realize cycle, The effect of improving electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

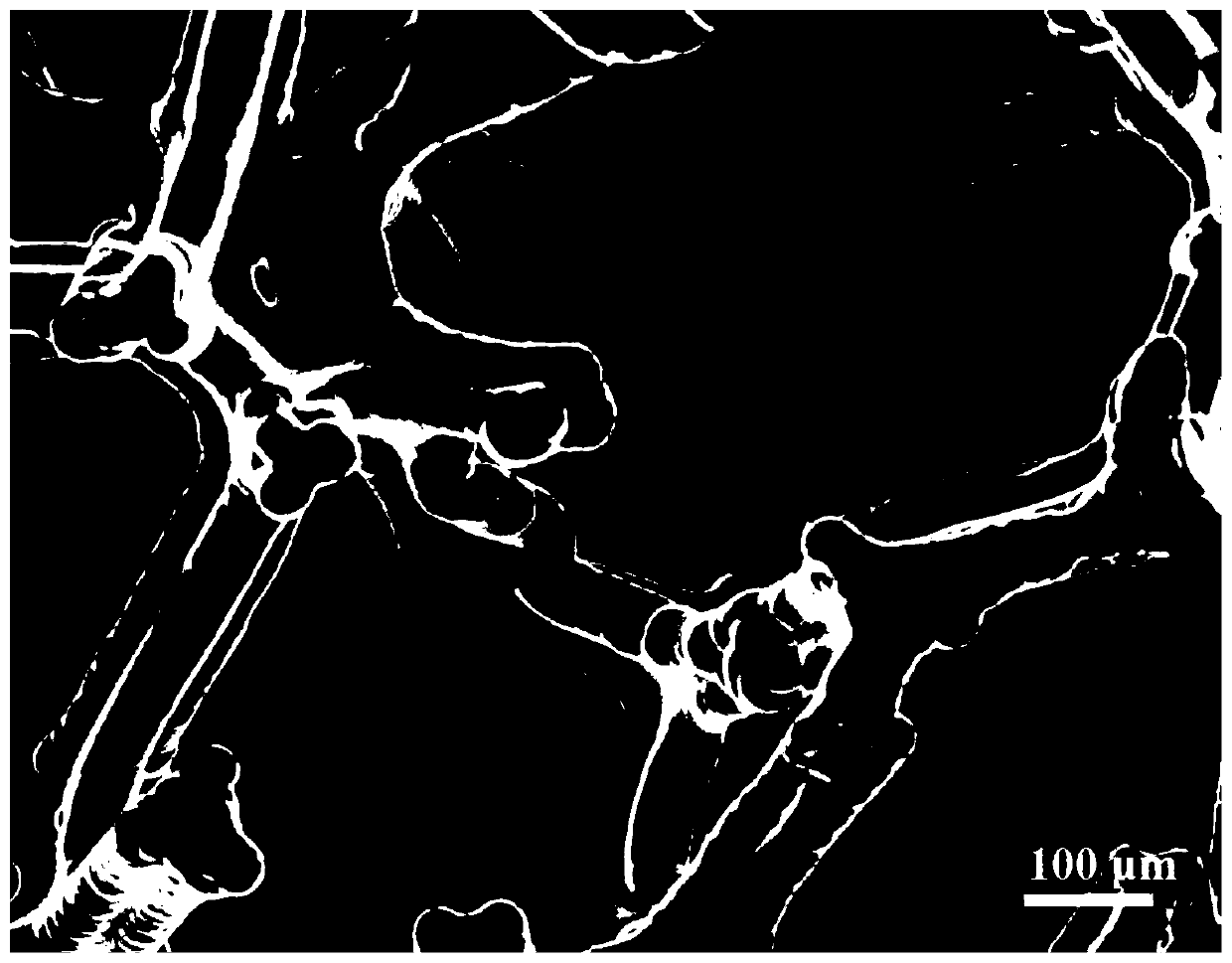

[0053] Spherical copper particles (120nm) were placed in an argon atmosphere at 600°C for 3h heat treatment to obtain a 3D copper skeleton with a porosity of 42% and a thickness of 100 μm ( figure 1 , is a 3D copper framework with an ordered structure and a suitable pore structure). The 3D copper skeleton is used as the working electrode, the metal lithium sheet is used as the counter electrode, and 1M LiTFSI / DOL:DME (volume ratio=1:1) contains 2wt.% LiNO 3 Assemble the button battery for the electrolyte, and conduct a charge-discharge cycle test. The test found that the 3D copper skeleton made in this case is composed of pure copper ( figure 2 ), achieving uniform dendrite-free lithium deposition and effectively avoiding the appearance of lithium dendrites. at 3mA / cm 2 Under the current density and 4mAh / cm2 areal capacity, the stable cycle can exceed 600 cycles (Table 1).

Embodiment 2

[0064] The 3D copper skeleton obtained in Example 1 is used as a working electrode, and then at a current density of 0.1mA / cm2, electroplate 5mAh / cm2 metal lithium onto the electrode to prepare a composite negative electrode material, and then form a composite negative electrode material with a graphene positive electrode rich in S Lithium-sulfur battery, in 1M LiTFSI / DOL:DME (volume ratio = 1:1) electrolyte solution containing 1wt.% LiNO3, at 0.5C, conduct charge-discharge cycle test. The corresponding test results are shown in Table 2.

Embodiment 3

[0075] Titanium, iron, nickel, copper, and tungsten particles (with a particle size of about 250nm) were placed in an argon atmosphere at 660°C for 4 hours of heat treatment to obtain a 3D titanium skeleton with a porosity of about 47% and a thickness of about 120μm. Skeleton, 3D nickel skeleton, 3D copper skeleton, 3D tungsten skeleton. These electrodes were respectively used as working electrodes, metal lithium sheets were used as counter electrodes, and 1M LiTFSI / DOL:DME (volume ratio=1:1) containing 2wt.% LiNO 3 Assemble the button battery for the electrolyte, and conduct a charge-discharge cycle test at a current density of 3mA / cm2 and an area capacity of 3mAh / cm2. The corresponding test results are shown in Table 3.

[0076] table 3

[0077]

[0078]

[0079] The results show that copper and titanium, as the 3D framework materials, can exhibit better cycle performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com