Heat treatment method for improving tensile plasticity of GH3690 alloy

A technology of GH3690 and heat treatment method, which is applied in the field of heat treatment process of GH3690 alloy, can solve the problems of no further improvement and less research on alloy tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Commercial GH3690 alloy pipes are used, and the composition is shown in Table 1.

[0025] Ni

Cr

Fe

C

Si

mn

S

Cu

≥58

27~31

7~11

≤0.05

≤0.5

≤0.5

≤0.015

≤0.5

[0026] (2) A commercial heat treatment furnace is used.

[0027] (3) Raise the furnace temperature to 1065°C-1075°C for 270-330 seconds.

[0028] (4) After the heat treatment is completed, the sample is air-cooled.

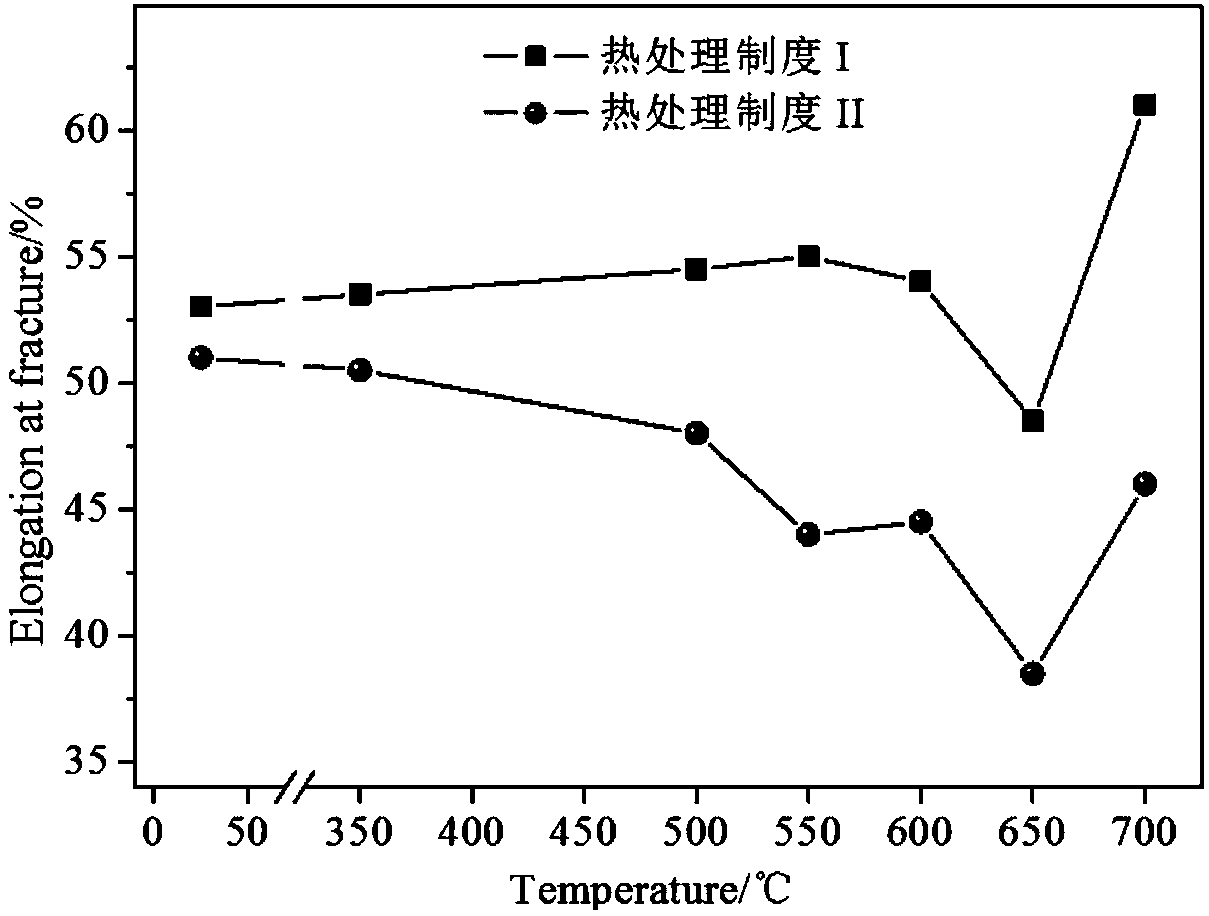

[0029] (5) The sample after heat treatment is carried out tensile test test under different temperatures, and the obtained result is as follows figure 1 shown. It can be seen that after heat treatment, the tensile plasticity of the alloy can reach more than 47.6% in the low plasticity zone, and the highest can reach 62.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com