Positive electrode material with low surface residual alkali as well as preparation method and application thereof

A positive electrode material and low surface technology, which is applied in the field of positive electrode materials with low surface residual alkali and its preparation, can solve the problems of poor dispersion and stability of slurry, impossibility of coating process, and poor compatibility of binders, etc. Achieve the effects of improving cycle life, improving anti-overcharge performance and rate performance, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

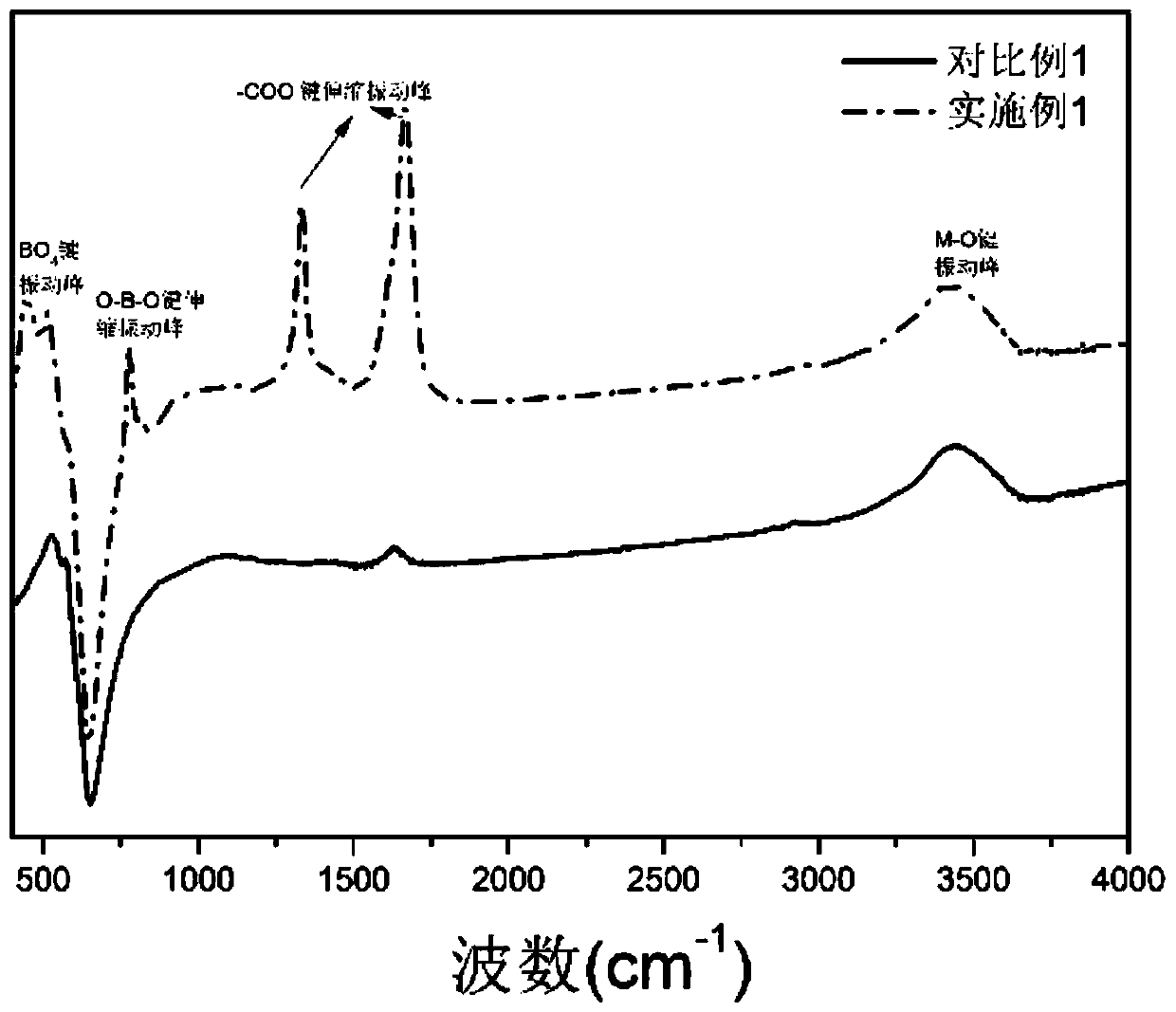

Embodiment 1

[0053] Weigh 50g of 1# sample in Comparative Example 1, 0.158g of boric acid and 0.460g of oxalic acid, grind and mix evenly, and sinter at 100°C for 2 hours, then sinter at 220°C for 4 hours to obtain positive electrode material 5#.

Embodiment 2

[0055] Weigh 50g of 1# sample in Comparative Example 1, 0.178g of diboron trioxide and 1.042g of lithium oxalate, grind and mix them evenly, sinter at 150°C for 2 hours, and then sinter at 260°C for 4 hours to obtain positive electrode material 6#.

Embodiment 3

[0057] Weigh 50g of 2# sample in Comparative Example 2, 0.79g of boric acid and 2.302g of oxalic acid, grind and mix evenly, and sinter at 110°C for 2 hours, then sinter at 240°C for 4 hours to obtain positive electrode material 7#.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com