Preparation method of galacto-mannan-oligosaccharides and application of galacto-mannan-oligosaccharides

A technology of galactomannan oligosaccharides and galactomannans, which is applied in the field of directional preparation of galactomannan oligosaccharides with a specific molecular weight, can solve problems such as patent vacancies, and achieve simple equipment, wide application range, and oligosaccharides high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

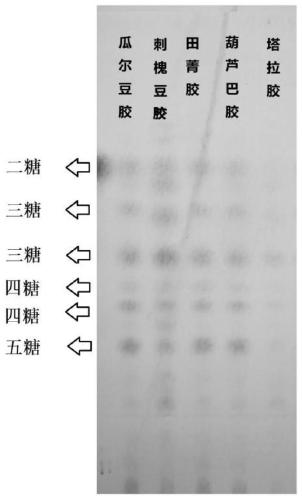

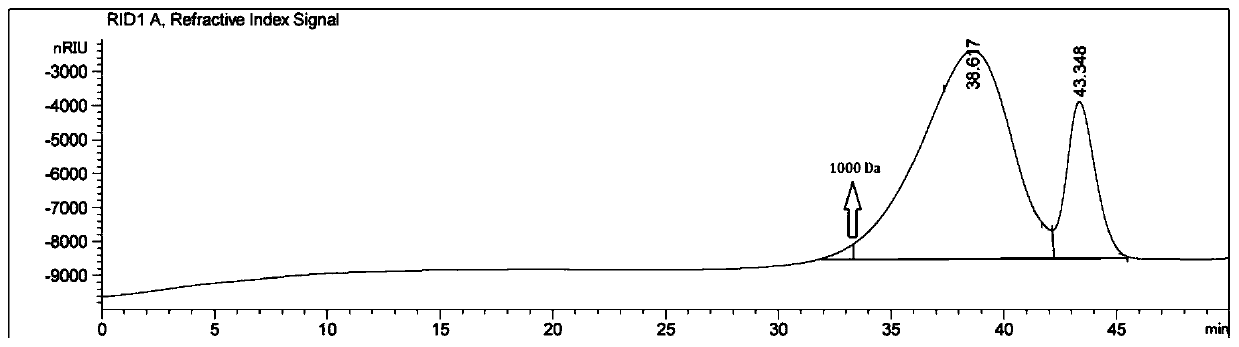

[0029] In 250mL of distilled water with pH 5.0, dissolve acid mannanase at a ratio of 2000U / g to galactomannan, then add 25g of locust bean gum, guar gum, kale gum, fenugreek gum, and Pull the glue and hydrolyze it at 45°C for 8 hours. After the enzymatic hydrolysis reaction, the reaction solution was inactivated in a boiling water bath for 10 minutes to obtain an enzymatic hydrolysis solution. After the obtained enzymolysis solution was centrifuged at 4000rpm for 20min, the precipitate was dried and weighed, and the supernatant was collected. The supernatant was intercepted by hollow fiber membranes with molecular weight cut-offs of 1000Da and 200Da respectively to obtain an oligosaccharide solution with a molecular weight in the range of 1000-200Da, which was freeze-dried to obtain dry oligosaccharide powder, which was weighed. The enzymatic hydrolysis precipitation yield and oligosaccharide yield are shown in Table 1. The results showed that when the acid mannanase was hy...

Embodiment 2

[0033] In 250mL of distilled water with pH 5.0, dissolve cellulase at a ratio of 2000U / g to galactomannan, then add 25g of locust bean gum, guar gum, kale gum, fenugreek gum, and tara gum , placed at 45 ° C for 8h hydrolysis. After the enzymatic hydrolysis reaction, the reaction solution was inactivated in a boiling water bath for 10 minutes to obtain an enzymatic hydrolysis solution. After the obtained enzymolysis solution was centrifuged at 4000rpm for 20min, the precipitate was dried and weighed, and the supernatant was collected. The supernatant was intercepted by hollow fiber membranes with molecular weight cut-offs of 1000Da and 200Da respectively to obtain an oligosaccharide solution with a molecular weight in the range of 1000-200Da, which was freeze-dried to obtain dry oligosaccharide powder, which was weighed. The yield of oligosaccharides is shown in Table 2. The results showed that when the cellulase was enzymatically hydrolyzed alone, the enzymatic hydrolysis wa...

Embodiment 3

[0037] In 250mL of distilled water with pH 5.0, dissolve acid mannanase and cellulase respectively according to the ratio of 1000U / g to galactomannan, then add 25g of locust bean gum, guar gum, squash gum, and gourd Ba gum and tara gum were hydrolyzed at 45°C for 8 hours. After the reaction, the reaction solution was inactivated in a boiling water bath for 10 minutes to obtain an enzymatic hydrolysis solution. After the obtained enzymolysis solution was centrifuged at 4000rpm for 20min, the precipitate was dried and weighed, and the supernatant was collected. The supernatant was intercepted by hollow fiber membranes with molecular weight cut-offs of 1000Da and 200Da respectively to obtain an oligosaccharide solution with a molecular weight in the range of 1000-200Da, which was freeze-dried to obtain dry oligosaccharide powder, which was weighed. The yield of oligosaccharides is shown in Table 3. The results showed that the combination of acid mannanase and cellulase for enzy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com