A kind of double-layer wave-absorbing material and preparation method thereof

A wave absorbing material, double-layer technology, applied in the field of wave absorbing materials, can solve the problems of less variable parameters, large material ratio, and limited wide application, etc., to achieve good wave absorption effect, enhance wave absorption performance, and broaden wave absorption. Band effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

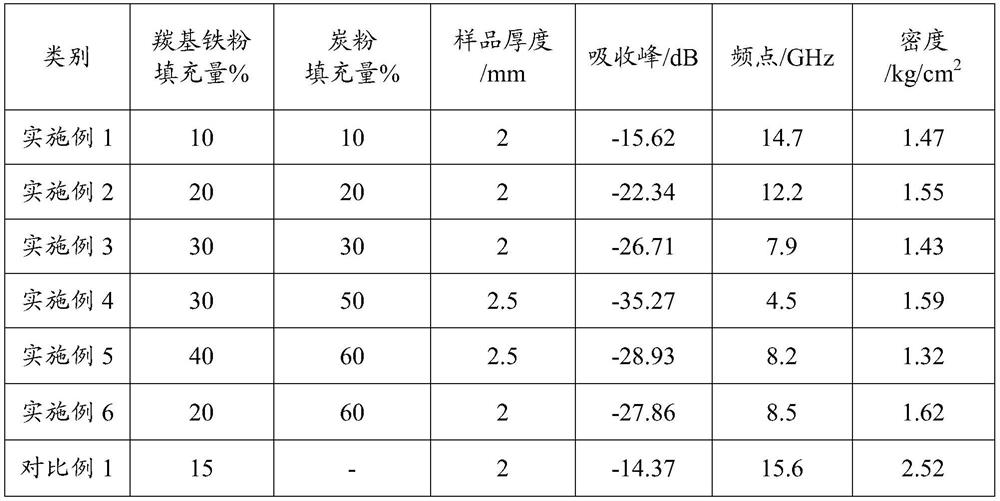

Examples

Embodiment 1

[0026] The carbonyl iron powder magnetic powder wave absorbing agent is ball-milled in a ball mill for 20 hours, impregnated with ethyl acetate, filtered, and dried to obtain the carbonyl iron powder after ball milling. The carbon powder is ball-milled in a ball mill for 8 hours, then impregnated with dilute hydrochloric acid with a mass fraction of less than 10%, filtered and dried to obtain the ball-milled carbon powder.

[0027] Mix 10 parts of carbonyl iron powder after ball milling with 70 parts of epoxy resin, 8 parts of absolute ethanol diluent, 9 parts of polyamide curing agent and 3 parts of organic bentonite anti-sedimentation agent, and then disperse and mix evenly with an ultrasonic instrument, Injected into a mold with a specification of 300*300*3mm, cured at room temperature and formed as the bottom layer, that is, the impedance layer, wherein the mass content of carbonyl iron powder in the impedance is 10%, and the thickness of the impedance layer is 1mm; after t...

Embodiment 2

[0029] The carbonyl iron powder magnetic powder wave absorbing agent is ball-milled in a ball mill for 20 hours, impregnated with ethyl acetate, filtered, and dried to obtain the carbonyl iron powder after ball milling. The carbon powder is ball-milled in a ball mill for 8 hours, then impregnated with dilute hydrochloric acid with a mass fraction of less than 10%, filtered and dried to obtain the ball-milled carbon powder.

[0030] Mix 20 parts of carbonyl iron powder after ball milling with 65 parts of epoxy resin, 5 parts of n-butanol diluent, 6 parts of dicyandiamide curing agent and 4 parts of polyamide wax anti-sedimentation agent, and use ultrasonic instrument to disperse and mix evenly Finally, it is injected into a mold with a specification of 300*300*3mm, cured at room temperature, and formed as the bottom layer, that is, the resistance layer, wherein the mass content of carbonyl iron powder in the resistance layer is 20%, and the thickness of the resistance layer is 1...

Embodiment 3

[0032] The carbonyl iron powder magnetic powder wave absorbing agent is ball-milled in a ball mill for 20 hours, impregnated with ethyl acetate, filtered, and dried to obtain the carbonyl iron powder after ball milling. The carbon powder is ball-milled in a ball mill for 8 hours, then impregnated with dilute hydrochloric acid with a mass fraction of less than 10%, filtered and dried to obtain the ball-milled carbon powder.

[0033] Combine 30 parts of carbonyl iron powder after ball milling with 60 parts of epoxy resin, 3 parts of acetone diluent, 5 parts of dicyandiamide and diaminodiphenyl sulfone (mass ratio is 1:1) curing agent and 2 parts of organic bentonite anti-sedimentation Mix the agent, use an ultrasonic instrument to disperse and mix evenly at a high speed, inject it into a mold with a specification of 300*300*3mm, and cure it at room temperature to form the bottom layer, that is, the impedance layer, wherein the mass content of carbonyl iron powder in the impedance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com