Environment-friendly molded pulp formation method and product

A pulp molding, environment-friendly technology, applied in pulp molding production and environment-friendly pulp molding production field, can solve problems such as unfavorable environmental protection, easy pollution, white water loss, etc., achieve good environmental protection, reduce dosage, save The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

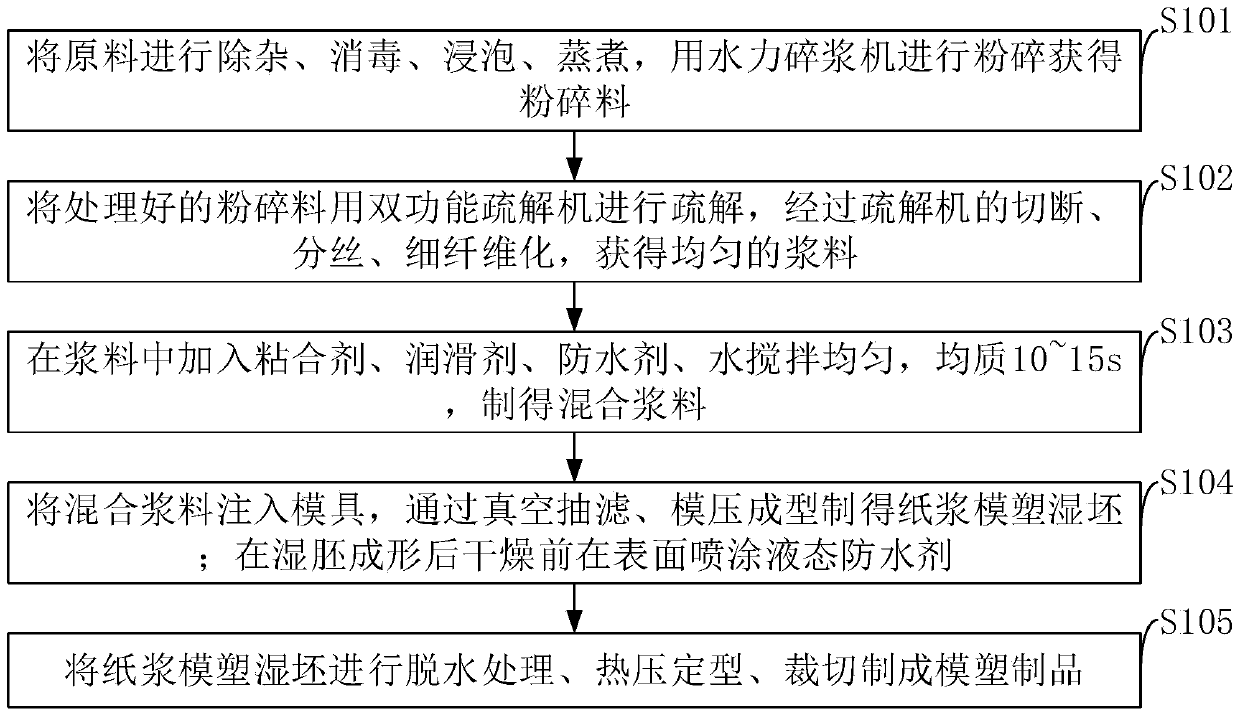

Method used

Image

Examples

Embodiment 1

[0043] The raw materials provided in this example are composed of 16 parts of bamboo, 12 parts of bagasse, 15 parts of straw, 18 parts of cotton husks, 8 parts of corn stalks and 8 parts of tea stalks according to the parts by mass.

[0044] In this embodiment, the additive amounts of the binder, the lubricant and the waterproofing agent are: 2%, 2.5%, and 1.5% by weight.

[0045] The binder used in this example is oxidized modified starch, the lubricant is a mixture of glycerin and silicone in a mass ratio of 1 to 1.5:1, and the waterproofing agent is anhydrous sodium carbonate and hydroxymethyl cellulose in a mass ratio of 1:1 mixture.

Embodiment 2

[0047] The raw materials provided by the embodiment of the present invention are composed of 18 parts of bamboo, 14 parts of bagasse, 19 parts of rice straw, 22 parts of cotton husks, 10 parts of corn stalks, and 10 parts of tea stems according to the parts by mass.

[0048] In this embodiment, the additive amounts of the binder, the lubricant and the waterproofing agent are: 4%, 2%, and 1.5% by mass.

[0049] The adhesive used in this embodiment is polyvinyl alcohol. The lubricant is a modified zinc stearate emulsion. The waterproofing agent is a 1:1 mass mixture of anhydrous sodium carbonate and stearic acid.

Embodiment 3

[0051] The raw materials provided by the embodiment of the present invention are composed of 17 parts of bamboo, 13 parts of bagasse, 17 parts of rice straw, 20 parts of cotton husks, 9 parts of corn stalks and 9 parts of tea stems according to the parts by mass.

[0052] In this embodiment, the additive amounts of the binder, the lubricant and the waterproofing agent are: 4.5%, 1.5%, and 1% by weight.

[0053] The adhesive used in this embodiment is carboxylated styrene-butadiene latex. The lubricant is polyethylene glycol. The waterproofing agent is a 1:1 mass mixture of anhydrous sodium carbonate and stearic acid.

[0054] The pulp molded products obtained in the above examples are green and environmentally friendly degradable materials, which can be directly discarded and naturally degraded into planting soil after being discarded; Spraying chemicals such as water-repellent agent on the surface after the blank is formed and before drying can greatly reduce the amount of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com