Composite coating special for lithium battery and preparation method thereof

A composite coating and lithium battery technology, applied in coatings, anti-corrosion coatings, starch coatings, etc., can solve the problems of corrosive substances, unsafe, dusty, etc., to improve performance, good adhesion, reduce heat The effect of mutation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

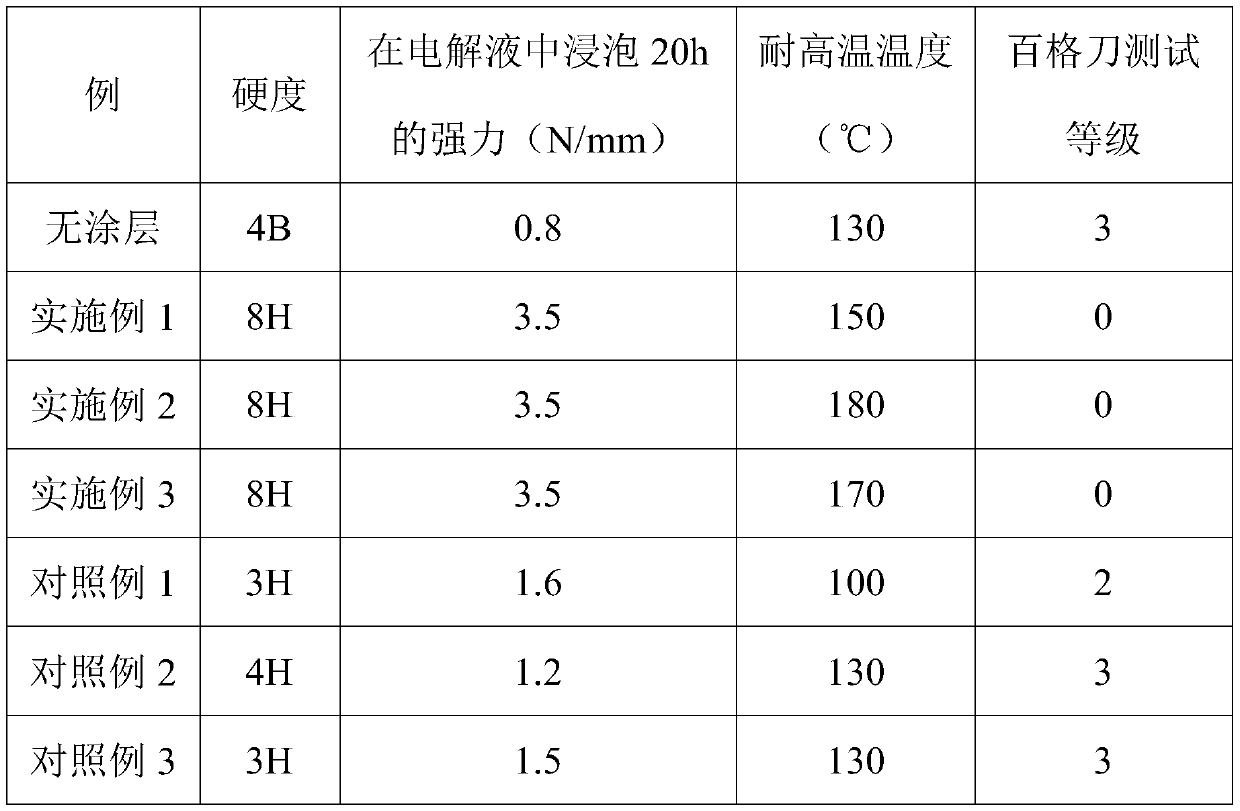

Examples

Embodiment 1

[0031] The invention provides a special composite coating for lithium batteries and a preparation method thereof. The special composite coating for lithium batteries includes the following raw materials in weight fractions: 20 parts of adhesive, 1 part of stabilizer, 5 parts of anticorrosion agent, secondary alkane 1 part of sodium sulfonate, 1 part of polyvinyl alcohol, 1 part of bentonite, 1 part of dextran, 10 parts of silica sol, 5 parts of solvent, and 3 parts of activated carbon.

[0032] The adhesive is water-based UV resin.

[0033] Described stabilizer is oleic acid.

[0034] The anticorrosion agent is water-based vaseline: water-based lanolin=1:1.

[0035] The solvent is water.

[0036] The activated carbon is in the form of black powder with a particle size of 100nm-200nm.

[0037] The special composite coating for lithium batteries can add 1 part of red dye according to user needs.

[0038] The special composite coating for lithium batteries is implemented by s...

Embodiment 2

[0046] The invention provides a special composite coating for lithium batteries and a preparation method thereof. The special composite coating for lithium batteries includes the following raw materials in weight fractions: 25 parts of adhesive, 2 parts of stabilizer, 6 parts of anticorrosion agent, secondary alkane 2 parts of sodium sulfonate, 1 part of polyvinyl alcohol, 2 parts of bentonite, 2 parts of dextran, 13 parts of silica sol, 8 parts of solvent, and 4 parts of activated carbon.

[0047] The adhesive is starch:shellac:water-based epoxy resin=1:1:3.

[0048] Described stabilizer is guar gum.

[0049] The anticorrosion agent is water-based vaseline.

[0050] Described solvent is deionized water.

[0051] The activated carbon is black powder with a particle size of 300-400nm.

[0052] In this example no dye was added.

[0053] The special composite coating for lithium batteries is implemented by brushing.

[0054] The invention provides a special composite coating...

Embodiment 3

[0061] The invention provides a special composite coating for lithium batteries and a preparation method thereof. The special composite coating for lithium batteries includes the following raw materials in weight fractions: 30 parts of adhesive, 3 parts of stabilizer, 7 parts of anticorrosion agent, secondary alkane 3 parts of sodium sulfonate, 2 parts of polyvinyl alcohol, 3 parts of bentonite, 3 parts of dextran, 15 parts of silica sol, 10 parts of solvent, and 5 parts of activated carbon.

[0062] The binder is water-based polyamide resin.

[0063] Described stabilizer is water glass.

[0064] The anticorrosion agent is water-based lanolin.

[0065] The solvent is water.

[0066] The activated carbon is black powder with a particle size of 300-500nm.

[0067] The special composite coating for lithium batteries can add 1 part of green dye according to user needs.

[0068] The special composite coating for lithium batteries is implemented by stick coating.

[0069] The inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com