Wear-resistant antiskid latex glove and making method thereof

A latex glove, anti-slip technology, applied in the field of latex gloves, can solve the problems of poor anti-slip performance and wear resistance, inability to apply fine operations, insufficient hand flexibility, etc., achieve excellent wear resistance and impact resistance, reduce Coefficient of friction, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

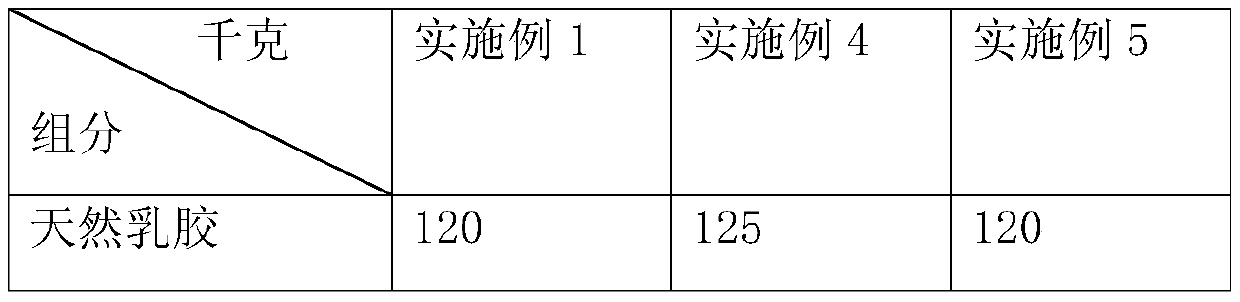

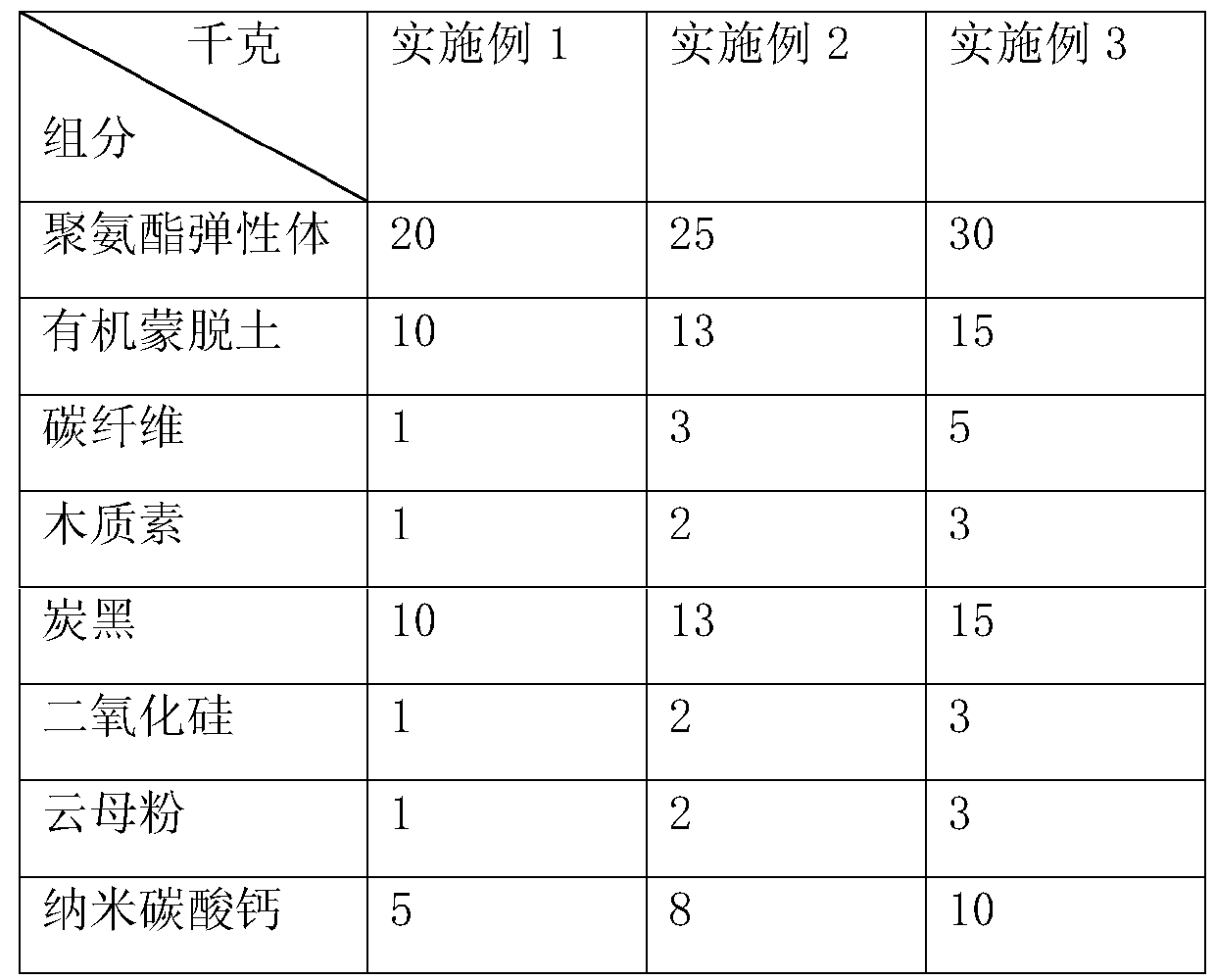

Examples

preparation example 1-3

[0047] In the following preparation example, the montmorillonite is selected from the montmorillonite sold by Lingshou County Hengchang Mineral Products Processing Factory with the item number J-009, and cetyltrimethylammonium chloride is selected from Shenzhen Oupent Technology Co., Ltd. Cetyltrimethylammonium Chloride is sold as model 1631.

preparation example 1

[0048] Preparation Example 1: Heat 50kg of deionized water to 70°C, add 1kg of montmorillonite, stir at a speed of 1500r / min for 1h, add 0.1kg of cetyltrimethylammonium chloride, and then add 30kg of deionized deionized water, stirred at 1000r / min for 1h, vacuum filtered, washed with deionized water for 3 times, and dried at 60°C for 22h to obtain organic montmorillonite.

preparation example 2

[0049] Preparation Example 2: Heat 65kg of deionized water to 75°C, add 2kg of montmorillonite, stir at a speed of 1800r / min for 1.5h, add 0.2kg of cetyltrimethylammonium chloride, and then add 40kg of deionized water, stirred at 1300r / min for 1.3h, vacuum filtered, washed with deionized water for 3 times, and dried at 65°C for 22h to obtain organic montmorillonite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com