P-type monocrystalline silicon battery front film coating structure and preparation method thereof

A single crystal silicon cell, crystalline silicon technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as unfavorable electrical performance, affecting cell conversion efficiency, and large carrier recombination, achieving good tunneling effect, improving Voc and Isc, the effect of improving transformation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

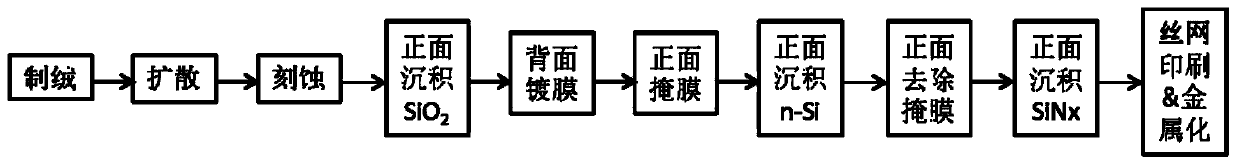

[0041] A method for preparing a front coating structure of a P-type monocrystalline silicon cell, comprising the following steps:

[0042] (1) After texturing, diffusion, and etching, SiO is deposited on the front surface of the battery by thermal oxidation 2 layer with a thickness of 2 nm;

[0043] (2) back coating;

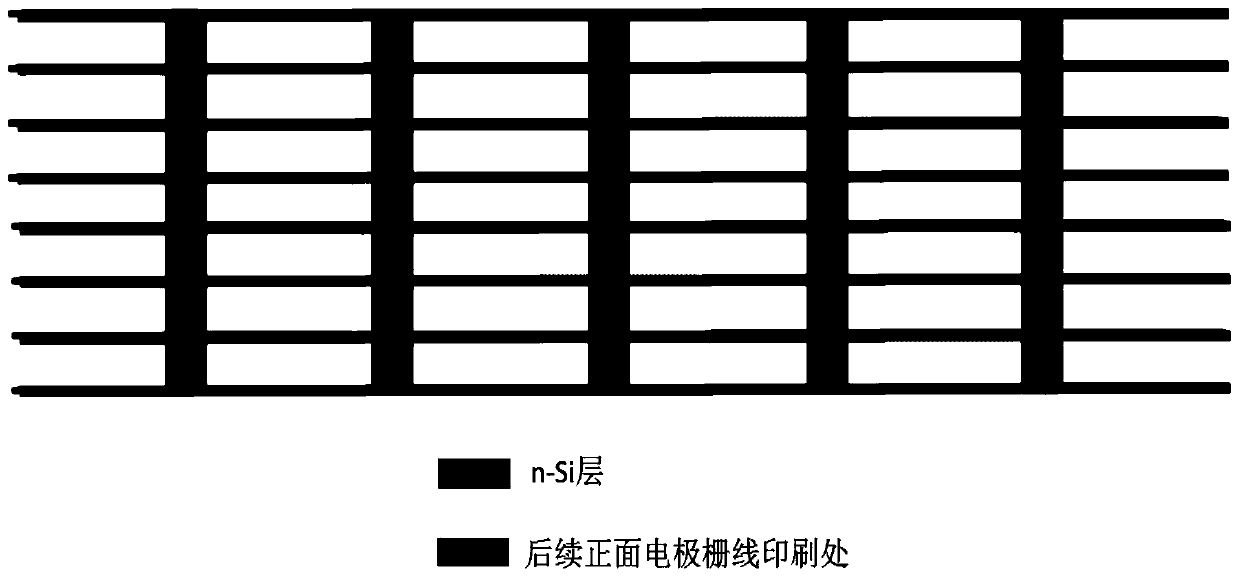

[0044](3) The mask method is selective. Deposit a P-doped polysilicon layer n-Si layer on the front of the battery, with a thickness of 20nm. The deposition method is PECVD. The pattern of the mask used must be consistent with the front silver electrode grid line of the subsequent screen printing The pattern of the pattern is complementary and consistent, ensuring that the pattern of the deposited polysilicon layer is consistent with the pattern of the front silver electrode grid line, so that the subsequent printing of the front silver electrode grid line can be overprinted in the pattern of the deposited polysilicon layer;

[0045] (4) Remove the battery fro...

Embodiment 2

[0050] A method for preparing a front coating structure of a P-type monocrystalline silicon cell, comprising the following steps:

[0051] (1) After texturing, diffusion, and etching, wet chemical method deposits SiO on the front surface of the battery 2 layer with a thickness of 1 nm;

[0052] (2) back coating;

[0053] (3) The mask method is selective. Deposit a P-doped polysilicon layer n-Si layer on the front of the battery with a thickness of 30nm. The deposition method is PECVD. The pattern of the mask used must be consistent with the front silver electrode grid line of the subsequent screen printing. The pattern of the pattern is complementary and consistent, ensuring that the pattern of the deposited polysilicon layer is consistent with the pattern of the silver electrode grid line, so that the subsequent printing of the front silver electrode line is overprinted in the pattern of the deposited polysilicon layer;

[0054] (4) Remove the battery front mask;

[0055] ...

Embodiment 3

[0059] A method for preparing a front coating structure of a P-type monocrystalline silicon cell, comprising the following steps:

[0060] (1) After texturing, diffusion, and etching, SiO is deposited on the front surface of the battery by thermal oxidation 2 layer with a thickness of 4 nm;

[0061] (2) back coating;

[0062] (3) Mask method Optionally, deposit a P-doped polysilicon layer n-Si layer on the front of the battery with a thickness of 10 nm, and the deposition method is LPCVD.

[0063] (4) Remove the battery front mask;

[0064] (5) Deposit a SiNx layer, 100nm, on the entire surface of the front, and the deposition method is PECVD;

[0065] (6) Screen print the front silver electrode grid to complete the battery production.

[0066] Among them, the side length of the battery is 157.75mm*157.75mm, and the diagonal diameter of the battery sheet is 210mm. There are 110 screen-printed front fine grids, each with a width and length of 0.032mm and 156.15mm, and a tot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com