Self-aroma multi-branched polymer fatliquor and preparation method thereof

A technology of polymer and fatliquoring agent, which is applied in animal husbandry, small raw hide/large raw hide/leather/fur treatment, leather impregnation, etc. It can solve the problems of application limitations, achieve enhanced bonding function, novel product structure, and avoid environmental pollution. pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

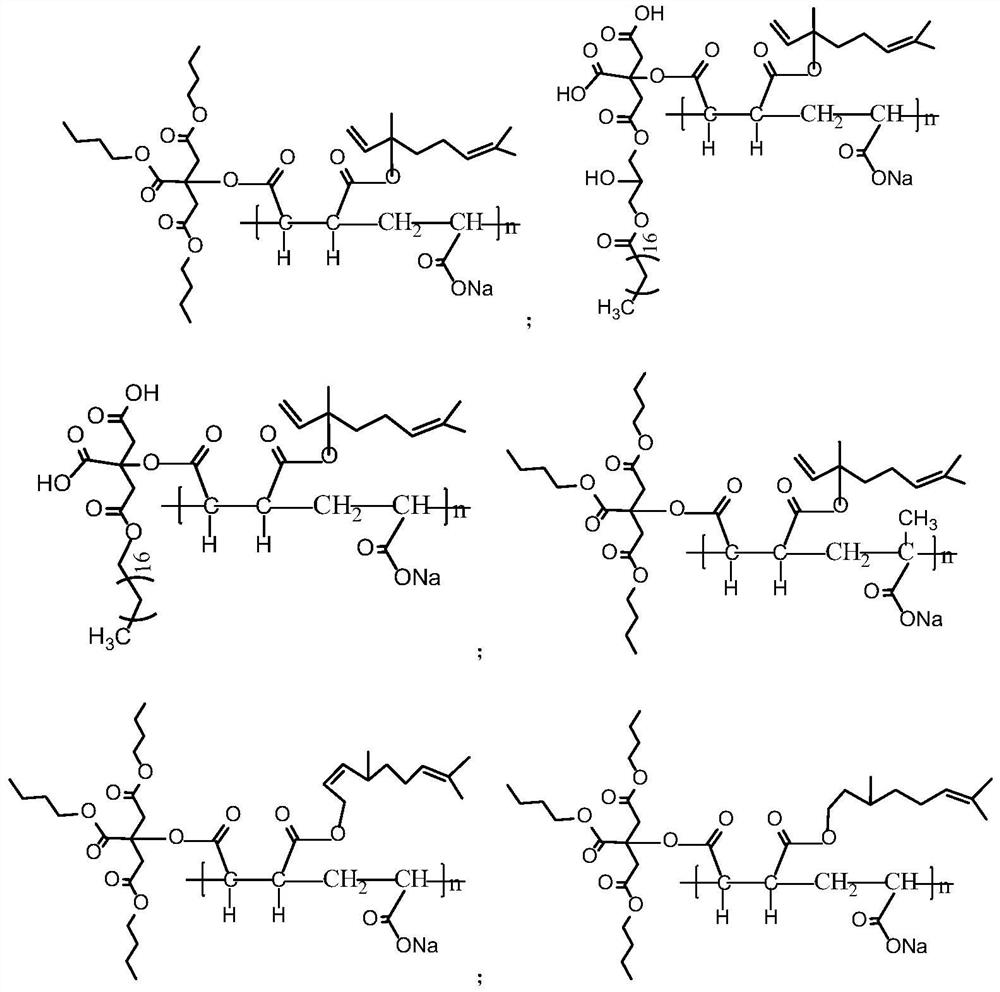

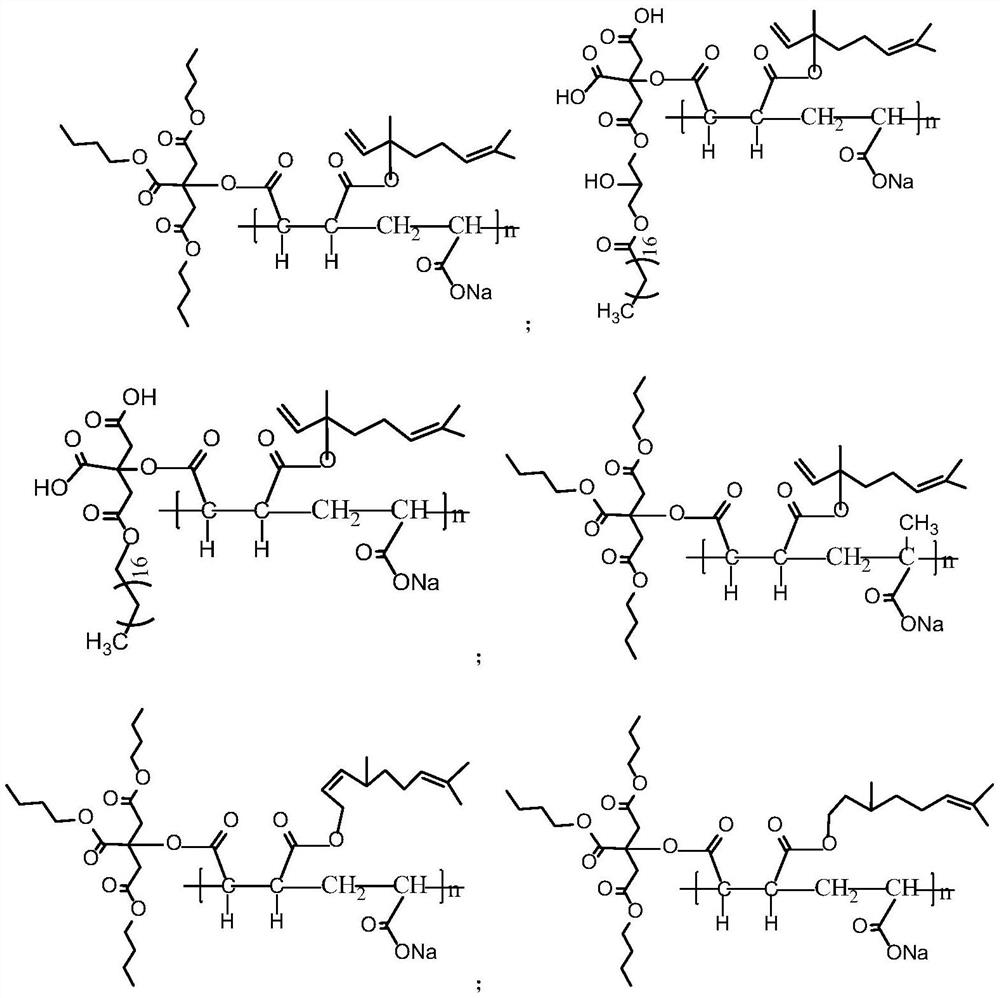

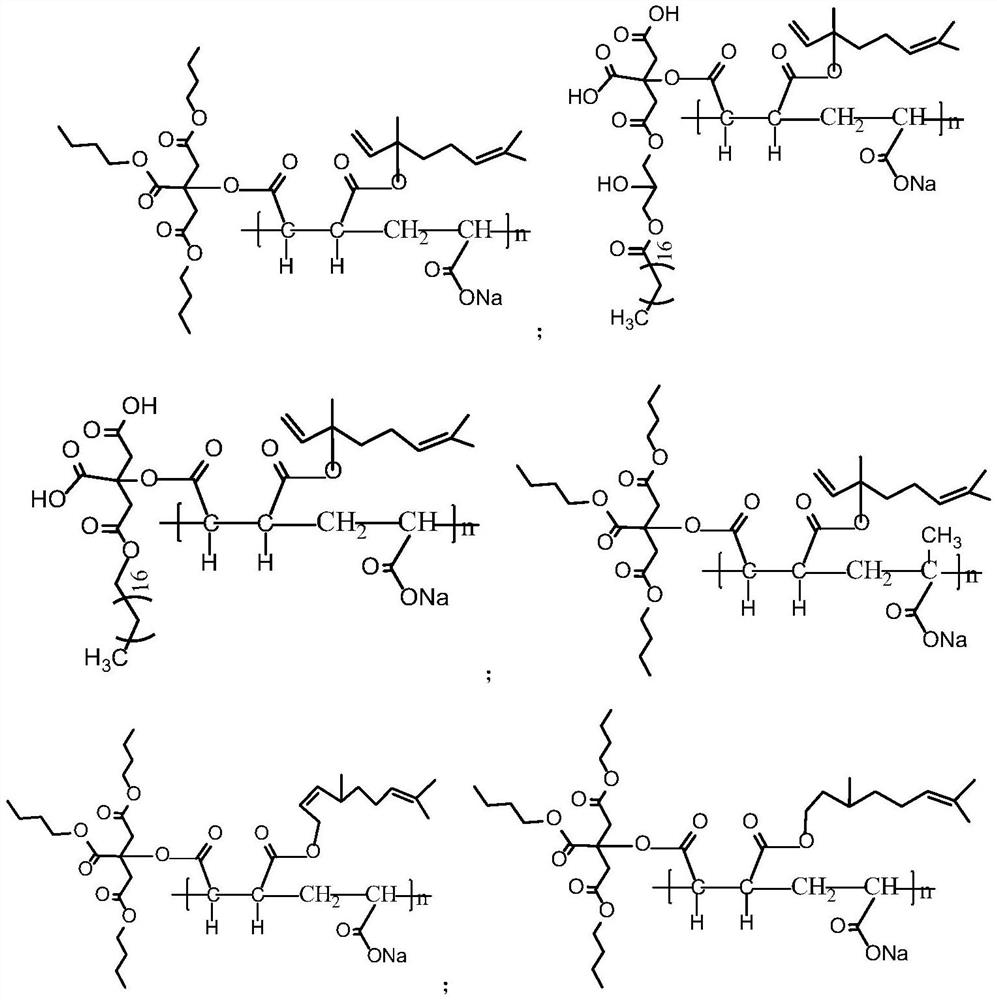

Image

Examples

Embodiment 1

[0036] (1) Esterification reaction. Add 180.22 parts of tributyl citrate, 77.13 parts of linalool and 25.73 parts of maleic anhydride into a 1000 mL three-necked flask equipped with a thermometer, a stirring device and a reflux condenser, and stir evenly. Then add 50 parts of ethylene glycol tert-butyl ether, raise the temperature to 85°C, and stir evenly. Add 2.83 parts of p-toluenesulfonic acid, control the temperature at 85±2°C, and time the reaction for 2 hours. Continue to heat up to 110°C, and stir for 1h. Lower the temperature to 85±2°C to obtain citrate linalool maleic ester.

[0037] (2) Free radical polymerization. Control the temperature at 85±2°C, fill the three-necked bottle with nitrogen, and replace it for 10 minutes. Take 0.2 parts of oil-soluble initiator azobisisobutyronitrile into the three-necked flask, and stir for 5 minutes. Take 19.85 parts of acrylic acid and drop them into the three-necked bottle at a constant speed, and the dropping time is 1.5 h...

Embodiment 2

[0040] (1) Esterification reaction. Add 275.34 parts of glyceryl stearic acid citrate, 61.7 parts of linalool and 25.73 parts of maleic anhydride into a 1000 mL three-necked flask equipped with a thermometer, a stirring device and a reflux condenser, and stir evenly. Then add 50 parts of ethylene glycol tert-butyl ether, raise the temperature to 90°C, and stir evenly. Add 3.63 parts of p-toluenesulfonic acid, control the temperature at 90±2°C, and time the reaction for 1 hour. Continue to heat up to 115°C, and stir for 3h. Lower the temperature to 90±2°C to obtain linalool maleic acid ester citrate.

[0041] (2) Free radical polymerization. Control the temperature at 90±2°C, fill the three-necked bottle with nitrogen, and replace it for 10 minutes. Take 0.37 parts of oil-soluble initiator benzoyl peroxide and add it into a three-necked flask, and stir for 5 minutes. Take 24.57 parts of acrylic acid and drop them into a three-necked flask at a constant speed for 1.5 hours....

Embodiment 3

[0044] (1) Esterification reaction. Add 221 parts of stearyl citrate, 77.13 parts of linalool and 26.96 parts of maleic anhydride into a 1000 mL three-necked flask equipped with a thermometer, a stirring device and a reflux condenser, raise the temperature to 60°C, and stir evenly. Then add 50 parts of ethylene glycol tert-butyl ether, raise the temperature to 90°C, and stir evenly. Add 4.88 parts of p-toluenesulfonic acid, control the temperature at 90±2°C, and time the reaction for 2 hours. Continue to heat up to 105°C and stir for 2h. Lower the temperature to 88±2°C to obtain linalool maleic ester of citrate.

[0045] (2) Free radical polymerization. Control the temperature at 88±2°C, fill the three-necked bottle with nitrogen, and replace it for 10 minutes. Take 0.35 parts of oil-soluble initiator, azobisisobutyronitrile, and add it into a three-necked flask, and stir for 5 minutes. Take 24.57 parts of acrylic acid and drop them into the three-necked flask at a consta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com