Independent hydraulic wheel brake

A technology of hydraulic wheels and brakes, applied in the direction of brake types, axial brakes, brake actuators, etc., can solve problems such as unsealable, difficult air exhaust, and danger of host equipment, so as to avoid oil stagnation, The effect of eliminating leakage and simplifying work difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

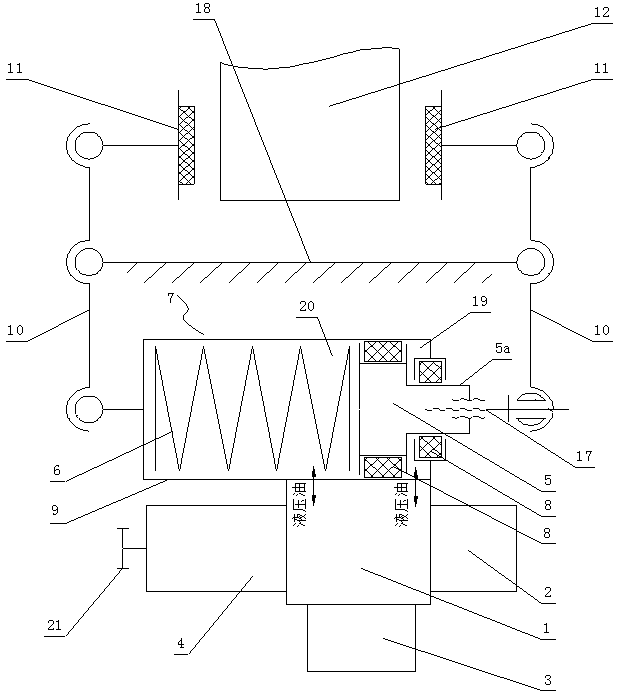

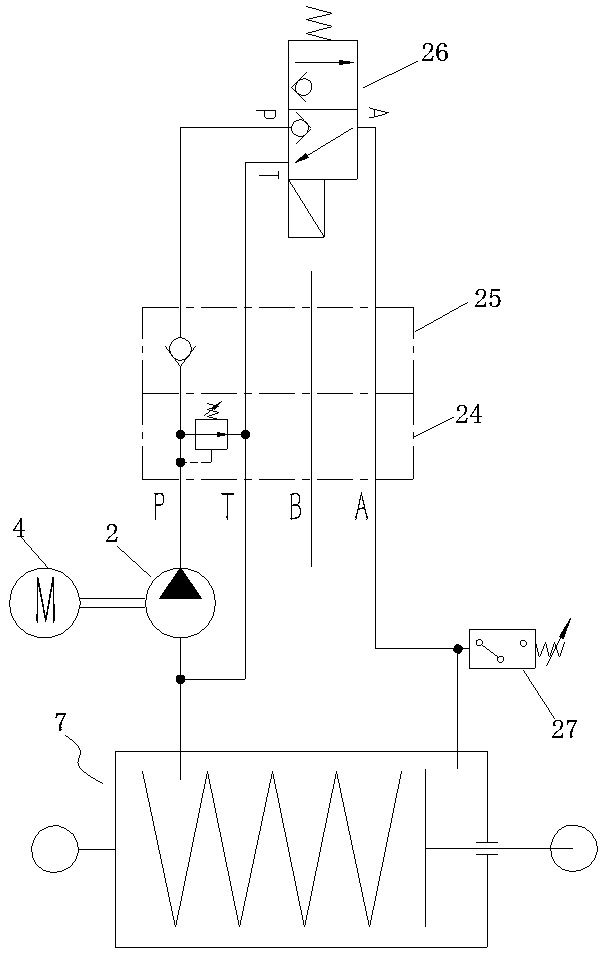

[0038] like Figure 1~2 As shown, an independent hydraulic wheel brake includes a pair of symmetrically arranged clamp arms 10, a pair of clamp seats 18, a symmetrically arranged pair of brake shoes 11, a valve block 1 with an internal oil passage, and a spring hydraulic cylinder 7 , The hydraulic pump 2 installed on the valve block 1, the hydraulic valve group 3 installed on the valve block 1. The hydraulic pump 2 is connected with the motor 4 . The motor 4 is provided with a hand wheel 21 coaxial with the output shaft of the motor.

[0039] The spring hydraulic cylinder 7 includes a hollow cylinder body 9 and a piston 5 arranged in the cylinder body 9 .

[0040] In the cylinder body 9, a pressure chamber 19 is provided on one side of the piston 5, a back pressure chamber 20 is provided on the other side of the piston 5, an oil inlet is provided at the pressure chamber 19, and an oil return port is provided at the back pressure chamber 20 , the oil passage of the valve blo...

Embodiment 2

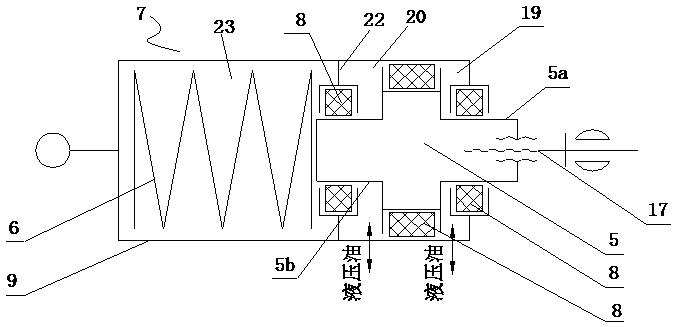

[0056] like image 3 As shown, Embodiment 1 is repeated, except that an oil barrier 22 is provided in the cylinder block 9 on the end face side of the piston 5 where the pressure end guide rod 5a is not provided. The cavity between the oil separating wall 22 and the end face of the piston where the pressure end guide rod 5 a is not provided is the back pressure cavity 20 . The oil separating wall 22 and the inner wall of the cylinder 9 on the side away from the piston 5 form a spring cavity 23 , and the spring 6 is located in the spring cavity 23 .

[0057] A back pressure end guide rod 5 b is provided on the end face of the piston 5 facing the back pressure chamber 20 , and the back pressure end guide rod 5 b can protrude into the spring cavity 23 through the oil separating wall 22 . One end of the spring 6 is fixedly connected with the end face of the cylinder 9 , and the other end is in contact with the end face of the back pressure end guide rod 5b. The contact part betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com