A method of using microorganisms to prevent and control soil shrinkage and cracking

A microbial control and soil technology, applied in soil protection, chemical instruments and methods, applications, etc., can solve the problems of difficult quantification of bacterial liquid, cementitious liquid and curing time, and achieve the purpose of reducing the degree of crack development, inhibiting cracking, and improving The effect of environmental coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] Repair for the soil of fissure development

[0084] Select the underwater soil in the Nanjing area as a test soil, and the wind-dried soil is 1 mm. A plastic petri dish in a diameter of 15 cm (a hole diameter is 3 mm), and the paper is filtered on the bottom pad at the bottom of the culture dish to prevent the soil particles from flowing out, then the 100 g of the soil is poured into the petriper, manually compacted, The thickness of the soil layer is about 0.5 cm in the curing depth D, and the processing area A is 180cm. 2 . Spray the water into the surface of the soil layer until saturated with a watering can (when the water is exudated from the bottom of the culture dish), then the sample is dry to the aqueous content of no change, the final sample moisture content It is 2%, the soil porosity N is 59%, and the viscosid content C is 22%.

[0085] Procedure:

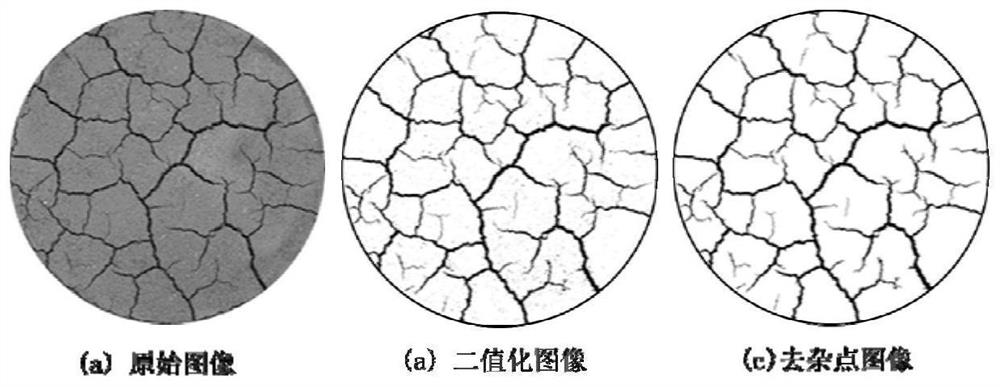

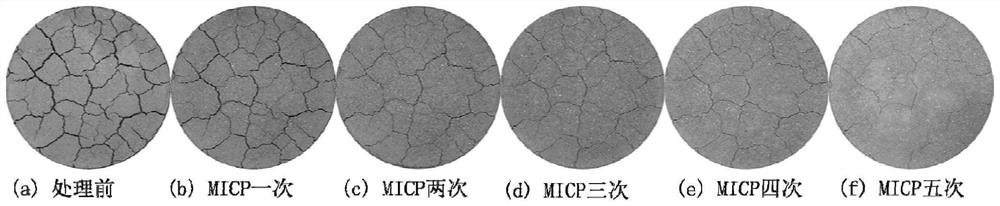

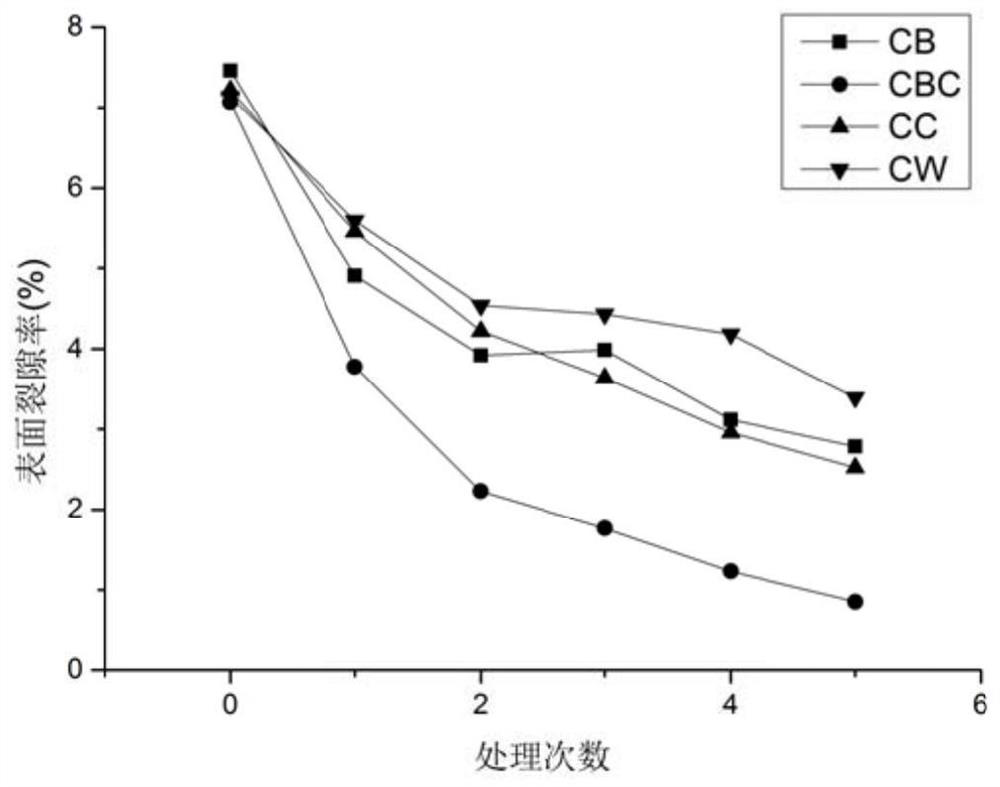

[0086] 1) Take a photo on the surface of the sample, and analyze its fracture rate with CIAS software to obtain th...

Embodiment 2

[0098] Repair for the soil of fissure development

[0099] The test soil adopted in this example is the same as in Example 1, and the repair method is substantially the same, and the difference is that the dry soil mass is 400 g, the curing depth D is about 2 cm, and the soil water head difference H is 2 cm. The fungus spray amount correction coefficient α is 1.5, the ratio of the amount of cementation and the amount of bacteria is 1.0, the bacterial liquid maintenance time correction coefficient β b Take the value of 1.5, the ceiling maintenance time correction coefficient β c The value is 3.0.

[0100] In this example, 4% of the bacterial solution was added to 96% of liquid medium during the preparation of a bacterial liquid to activate 24 hours; the concentration of urea and calcium chloride in the cement solution was 0.5 mol / L.

[0101] Analysis by CIAS software is analyzed by the initial fracture rate R sc For 8%, calculated by relations (2) ~ (5) to obtain the amount of ba...

Embodiment 3

[0104] Repair for the soil of fissure development

[0105] The test soil employed in this embodiment is the same as that of Example 1, and the repair method is substantially the same, and the liquid mass is 1000 g, the solidified depth D is about 5 cm, and the soil water head difference H is 5 cm. The fungus spray amount correction coefficient α is 2.0, the amount of the cementation is used and the ratio of the bacterial liquid is 1.5, and the bacterial liquid maintenance time correction coefficient β b Take the value of 2.0, the ceiling maintenance time correction coefficient β c The value is 5.0.

[0106] In this example, 5% of the bacterial liquid was added to 95% of the liquid medium during the preparation of the bacterial liquid to activate 24 hours; the concentration of urea and calcium chloride in the cement solution was 1.0 mol / L.

[0107] Analysis by CIAS software is analyzed by the initial fracture rate R sc 9%, calculated according to the relationship (2) ~ (5) to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com