Failure fracture cleaning method and solution for cleaning

A technology for cleaning solutions and fractures, used in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc. It can solve the problem that the type and dosage of corrosion inhibitors are not clearly defined, and the removal effect of corrosion products on fractures is weak. , the actual use of technical personnel confusion and other problems, to avoid irreversible damage, convenient preparation, easy to master the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

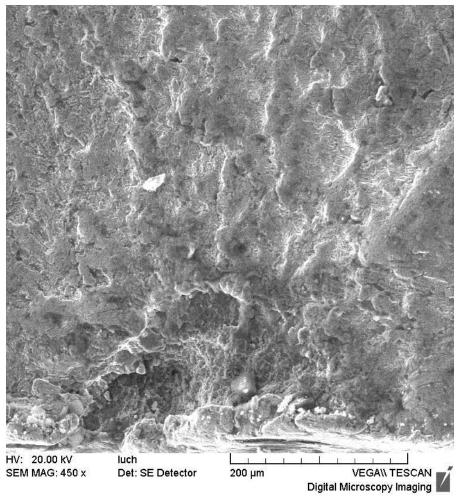

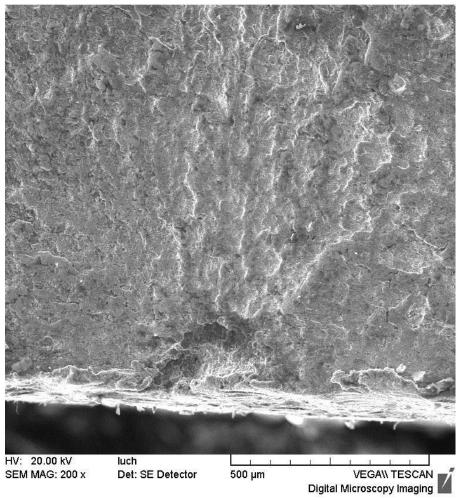

[0042] The invention provides a solution for cleaning invalid fractures. Hydrochloric acid: urotropine (hexamethylenetetramine): deionized water is configured as a cleaning solution at a ratio of 1:0.1:100 to clean the fracture sample. The invention relates to the removal of corrosion products on the failure fracture surface of carbon steel materials, and prepares qualified microscopic analysis samples, belonging to the technical field of fracture analysis of failure components.

[0043] Preferably, 1000 ml of solution is prepared according to 10 ml of hydrochloric acid, 1 g of urotropine and deionized water for cleaning.

[0044] A method for cleaning invalid fractures of the present invention and a solution for cleaning, comprising the following steps:

[0045] S1. Use a soft brush to clean the sand and loose covering on the surface of the fracture;

[0046] S2. Use acetone solution and an ultrasonic cleaner to ultrasonically clean the fracture to further remove the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com