Method for preparing personalized porous antibacterial dental root implant

A technology for implants and roots, which is applied in the field of preparation of personalized porous antibacterial root implants, which can solve the problems of difficulty in obtaining initial stability, secondary surgical trauma, and long implant treatment, so as to weaken or eliminate the stress shielding effect, The effect of avoiding osteonecrosis and shortening the treatment cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

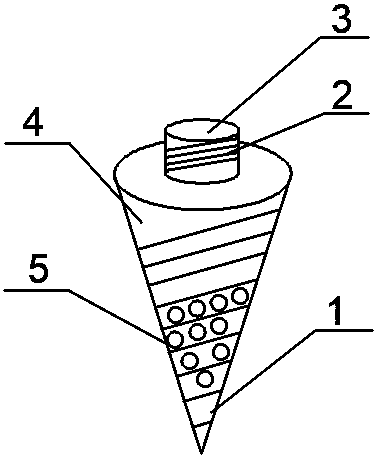

Image

Examples

Embodiment Construction

[0026] Its preparation method comprises the following steps:

[0027] Step 1: Preparation of root material titanium alloy composite powder. The sintering ratio is 98%Ti+1.5%Zn+1.0%Mg+0.5%Ag (mass fraction) with an average particle size of 21.2μm Ti, 30μm Zn, 55-100μm Mg, Ag mixed nano powder in drying Dry in the box at 150°C for 11 hours, mechanically mix the above powder in a QM-3SP4J planetary ball mill for 24 hours, mix the powder evenly and dry it at 80°C for 1 hour to obtain metal powder;

[0028] Step 2: 3D printing model construction. The data obtained by scanning the scanned area with MIMICS software were separated and reconstructed to obtain a three-dimensional model of the tooth root and abutment area to be extracted. Use Magic software to digitally design the 3D model and adjust the printing parameters as the implant model to be printed;

[0029] Step 3: Laser 3D printing molding. Copy the data of the printed implant model to the 3D printer for printing, set the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com