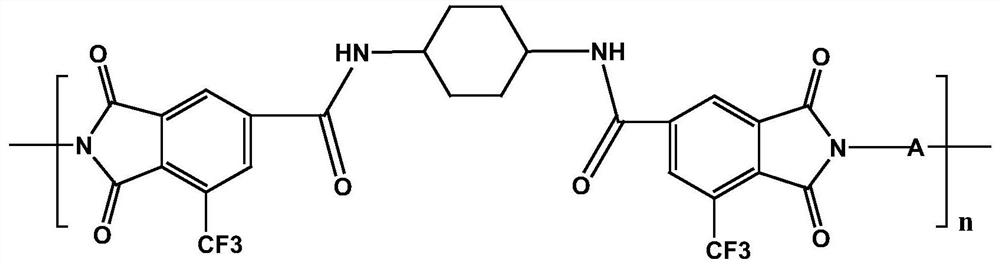

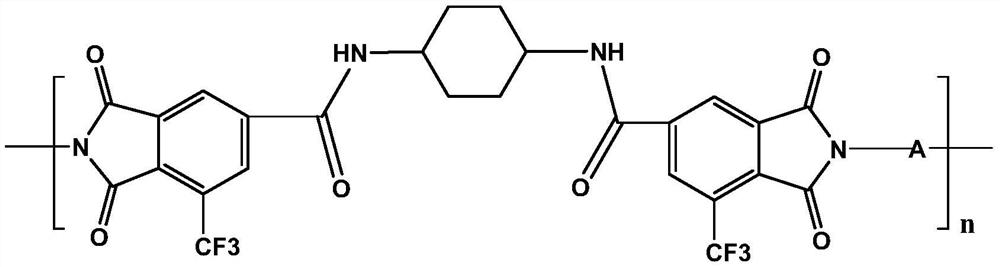

Highly transparent and low-expansion polyimide film for flexible display and preparation method thereof

A polyimide film and flexible display technology, which is applied in the field of high-transparency and low-expansion polyimide film for flexible display and its preparation, can solve the problems of low light transmittance, achieve good film-forming performance and low production cost , Low expansion thermal stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) 0.143g (2wt%) β-eucryptite and 40.375g DMAc are added to a four-necked flask for ultrasonic dispersion, so that they are fully dispersed in an organic solvent to form a uniform dispersion;

[0037](2) Add 1.081g of PDA monomer into the β-eucryptite organic solvent dispersion four-necked flask with nitrogen gas, stir until it dissolves completely;

[0038] (3) Weigh 6.044g of 1,4-bis(3,4-dicarboxylic acid-5-trifluoromethylamidophenyl)cyclohexane dianhydride and add it to the above solution in batches under stirring conditions. In situ polymerization at ℃ for 4 hours to obtain a polyamic acid solution with a solid content of 15 wt %;

[0039] (4) Add 3.036g triethylamine and 3.063g acetic anhydride to the above polyamic acid solution for chemical imidization, and react at 30°C for 8 hours to obtain a polyimide solution;

[0040] (5) Cast the obtained polyimide solution on ultra-flat glass, and then place it in an oven at 80° C. to dry for 24 hours to obtain a highly ...

Embodiment 2

[0043] (1) 0.285g (4wt%) β-eucryptite and 40.375g DMAc were added to a four-necked flask, and ultrasonically dispersed at room temperature to fully disperse it in an organic solvent to form a uniform dispersion;

[0044] (2) Add 1.081g of PDA monomer into the β-eucryptite organic solvent dispersion four-necked flask with nitrogen gas, stir until it dissolves completely;

[0045] (3) Weigh 6.044g of 1,4-bis(3,4-dicarboxylic acid-5-trifluoromethylamidophenyl)cyclohexane dianhydride and add it to the above solution in batches under stirring conditions. In situ polymerization at ℃ for 4 hours to obtain a polyamic acid solution with a solid content of 15 wt %;

[0046] (4) Add 3.036g triethylamine and 3.063g acetic anhydride to the above polyamic acid solution for chemical imidization, and react at 30°C for 8 hours to obtain a polyimide solution;

[0047] (5) Cast the obtained polyimide solution on ultra-flat glass, and then place it in an oven at 80° C. to dry for 24 hours to obt...

Embodiment 3

[0050] (1) 0.428g (6wt%) β-eucryptite and 40.375g DMAc were added to a four-necked flask, and ultrasonically dispersed at room temperature to fully disperse it in an organic solvent to form a uniform dispersion;

[0051] (2) Add 1.081g of PDA monomer into the β-eucryptite organic solvent dispersion four-necked flask with nitrogen gas, stir until it dissolves completely;

[0052] (3) Weigh 6.044g of 1,4-bis(3,4-dicarboxylic acid-5-trifluoromethylamidophenyl)cyclohexane dianhydride and add it to the above solution in batches under stirring conditions. In situ polymerization at ℃ for 4 hours to obtain a polyamic acid solution with a solid content of 15 wt %;

[0053] (4) Add 3.036g triethylamine and 3.063g acetic anhydride to the above polyamic acid solution for chemical imidization, and react at 30°C for 8 hours to obtain a polyimide solution;

[0054] (5) Cast the obtained polyimide solution on ultra-flat glass, and then place it in an oven at 80° C. to dry for 24 hours to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com