Cranberry instant powder and preparation method thereof

A technology of cranberry powder and direct drinking powder, which is applied in the direction of food science and the like, can solve the problems of shortening the storage time of dry particles, weakening the efficacy of cranberry, improving the uniformity of mixing, etc., and achieves rapid and automatic uniform mixing, The effect of improving the look and feel and prolonging the storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Recipe 1:

[0051]

[0052] Production Process:

[0053] 1) Weighing, pulverizing, and sieving: Weigh cranberry powder, excipients erythritol, and xylitol to pulverize, pass through an 80-mesh sieve, and set aside;

[0054] 2) Dry blending and granulation: Mix the cranberry powder, erythritol, and xylitol in the formula amount evenly in the automatic high-efficiency mixing equipment, add 30% ethanol to make the soft material, and pass it through a 20-mesh sieve. wet particles;

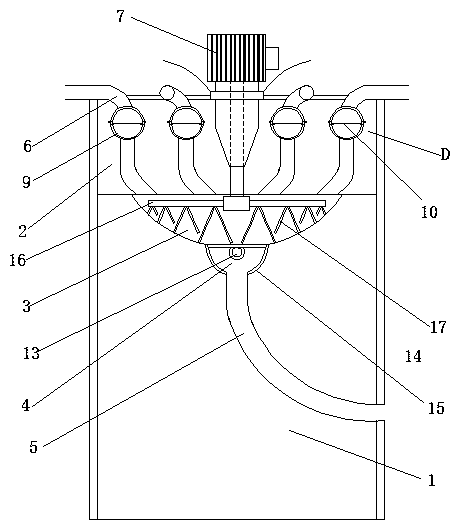

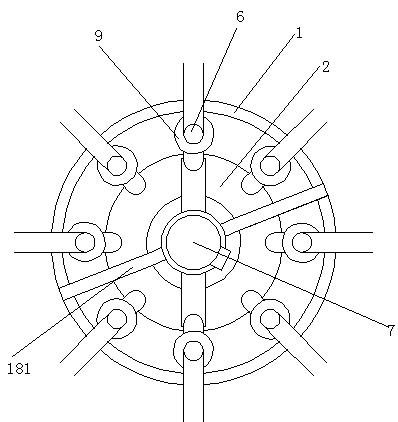

[0055] Refer to attached Figure 1-5 As shown, the automatic high-efficiency mixing equipment includes a mixing tank 1, and the mixing tank 1 includes a feeding tank 2, a mixing tank 3, a feeding tank 4 and a feeding pipe 5 from top to bottom, and the feeding tank 2 is a cylindrical tank. Open structure, the stirring tank 3 is provided with a circle of feed pipe 6, and the feed pipe 6 is provided with a circle, similar to an octopus structure, each feed pipe 6 has an S-shaped section, and ...

Embodiment 2

[0079] Recipe 2:

[0080]

[0081] Production Process:

[0082] 1) Weighing, pulverizing, and sieving: Weigh cranberry powder, prickly pear powder, prickly pear powder, roselle powder, excipients erythritol and xylitol, and pass through an 80-mesh sieve. spare;

[0083] 2) Dry blending and granulation: After mixing the cranberry powder, prickly pear powder, prickly pear powder, roselle powder with erythritol and xylitol in the formula amount, prepare soft materials and prepare wet granules (Concrete preparation process is the same as embodiment 1);

[0084]3) Drying: Dry the wet granules with an electric heating blower device with a self-rotating cylinder, dry them at 35°C for 15-30 minutes, and control the moisture content to ≤10% to obtain dry granules (the specific preparation process is the same as in Example 1);

[0085] 4) Grain sizing: use a 30-mesh sieve to sieve the dried granules;

[0086] 5) Filling: Fill the above-mentioned qualified particles into aluminum-...

Embodiment 3

[0099] Recipe 3:

[0100]

[0101] Production Process:

[0102] 1) Weighing, pulverizing, and sieving: Weigh cranberry powder, elderberry concentrated juice powder, roselle powder, white grape juice powder, red beet juice powder, auxiliary materials erythritol, xylitol Crush, pass through 80 mesh sieve, and set aside;

[0103] 2) Dry blending and granulation: mix the cranberry powder, elderberry concentrated juice powder, roselle powder, white grape juice powder, red beet juice powder with erythritol and xylitol in the prescribed amount, and then add 50% ethanol system soft material, wet particle (concrete preparation process is with embodiment 1;

[0104] 3) Drying: Dry the wet granules with electric heating blower equipment with a self-rotating cylinder, dry at 35°C for 15-30 minutes, and control the moisture content to ≤10%, to obtain dry granules (the specific preparation process is the same as formula 1, and the production process ( 3));

[0105] 4) Grain sizing: u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com