Composite material, preparation method of composite material, and lithium ion battery

A technology of lithium-ion batteries and composite materials, which is applied in the field of composite materials and its preparation, can solve the problems that the performance does not meet the requirements of industrial production and application, and has not been effectively improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

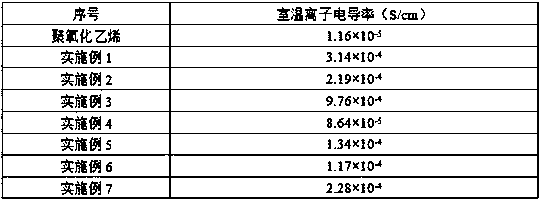

[0029] A composite material, the composite material includes an oxide electrolyte and nano attapulgite, and the oxide electrolyte covers the nano attapulgite.

[0030] Further, the thickness of the oxide electrolyte coating layer is ≤20 μm, and the lithium ion conductivity of the oxide electrolyte coating layer is on the order of 10 -5 S / cm to 10 -3 S / cm. The rod crystals of the nano-attapulgite are 100nm-50μm long and 10nm-120nm wide, and the nano-attapulgite has been commercialized.

[0031] Further, the oxide electrolyte is lithium phosphate, lithium titanate, lithium titanium phosphate, lithium titanium aluminum phosphate, lithium lanthanum titanate, lithium lanthanum tantalate, lithium germanium aluminum phosphate, lithium silicon phosphate, lithium aluminosilicate, three One or more of boron oxide doped lithium phosphate, lanthanum zirconium lithium oxygen, lanthanum zirconium aluminum lithium oxygen, niobium doped lithium lanthanum zirconium oxide, tantalum doped li...

Embodiment 1

[0047] A method for preparing a composite material, comprising the steps of:

[0048] Step 1: In terms of molar parts, 140.00 parts of lithium nitrate, 420.00 parts of phosphoric acid, and 280.00 parts of titanium sulfate are configured into a mixed aqueous solution, and citric acid and 12.4 parts by mass of nano-attapulgite are added to the mixed aqueous solution, wherein the metal cation and lemon The molar ratio of the acid is 1:1.2, stir evenly and add ammonia water to keep the pH value of the solution at 7, continue to stir until a gel is formed, heat to 60°C and perform vacuum treatment, and the mixed system is obtained after the aqueous solution is completely volatilized. The mixed system was microwaved at 180°C for 2 hours, cooled to room temperature, washed with deionized water, and vacuum-dried at 60°C for 12 hours to obtain the precursor powder A system;

[0049] Step 2: Heat the precursor powder A system to 400°C for 0.5h to eliminate residual organic matter, then ...

Embodiment 2

[0055] A method for preparing a composite material, comprising the steps of:

[0056] Step 1. In molar parts, 140.00 parts of lithium sulfate, 60.00 parts of lanthanum nitrate, 35.00 parts of zirconium chloride, and 5.00 parts of niobium pentachloride are configured into a mixed aqueous solution, and citric acid and 4.2 parts by mass of nano Attapulgite, wherein the molar ratio of metal cations to citric acid is 1:1.6, stir evenly and add ammonia water to keep the pH value of the solution at 7, continue stirring until a gel is formed, heat to 70°C and perform vacuum treatment, After the aqueous solution is completely volatilized, a mixed system is obtained. The mixed system is microwaved at 200°C for 4 hours, cooled to room temperature, washed with ethanol, and vacuum-dried at 90°C for 24 hours to obtain the precursor powder A system;

[0057] Step 2: Heat the precursor powder A system to 490°C for 0.9 hours to eliminate residual organic matter, then sinter at 900°C, and after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com