Composite material, preparation method thereof and lithium ion battery comprising composite material

A lithium-ion battery and composite material technology, which is applied in the field of composite materials and its preparation, can solve the problems of easy expansion and falling off of the negative electrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

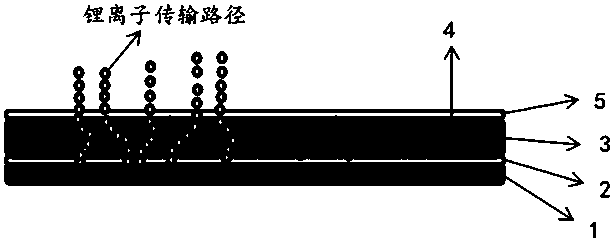

[0031] A composite material, the composite material includes a sulfide electrolyte 41 and a nano-attapulgite 42, and the sulfide electrolyte 41 covers the nano-attapulgite 42.

[0032] Further, the thickness of the sulfide electrolyte 41 is ≤20um, and the lithium ion conductivity of the sulfide electrolyte 41 is on the order of 10 -5 S / cm to 10 -2 S / cm; the nano-attapulgite 42 is a commercial nano-attapulgite, and the rod crystals of the nano-attapulgite 42 are 100nm-50um in length and 10nm-120nm in width.

[0033] Further, the sulfide electrolyte 41 is a combination of one or more of the following substances: aLi 2 S·bP 2 S 5 cLiX, where X represents halogen elements, 20≤a≤80, 20≤b≤40, 0≤c≤20; aLi 2 S·bP 2 S 5 cMeS, where Me is Si, Ge, Sn, Al or B, 20≤a≤80, 20≤b≤40, 0≤c≤20; aLi 2 S·bP 2 S 5 · cP 2 o 5 , where 674-a Si 1-a P a S 4 , where 02 S·(30−a)P 2 S 5 ·aP 2 S 3 , where 02 S·bSiS 2 , where 50≤a≤70, 30≤b≤50; Li 4-a Si 1-a al a S 4 , where 02 S·bSiS ...

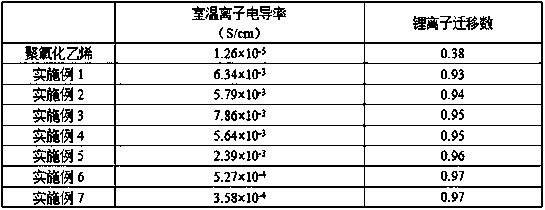

Embodiment 1

[0049] A method for preparing a composite material, comprising the steps of:

[0050] Step 1: In terms of molar parts, weigh 40 parts of Li in an argon environment 2 Dissolve S in absolute ethanol, add 1.50 parts of nano-attapulgite to soak fully, then vacuumize at room temperature, then heat to 50°C, remove solvent anhydrous ethanol, and obtain nano-attapulgite composite coated with lithium sulfide Material;

[0051] Step 2: In terms of molar fractions, under an argon atmosphere, the nano-attapulgite composite material coated with lithium sulfide obtained in step 1, 13.5 parts of P 2 S 5 , put them together with zirconia balls into a bowl made of zirconia, seal the bowl under an argon atmosphere, install the bowl on a ball mill, rotate at a speed of 200r / min, and mix for 20 hours to obtain a fully mixed In system A, add the mixed powder of system A into a quartz tube, heat it after vacuum sealing, the heating temperature is 400°C, and the heating time is 2 h to obtain a co...

Embodiment 2

[0056] A method for preparing a composite material, comprising the steps of:

[0057] Step 1: In terms of molar parts, weigh 100 parts of Li in an argon atmosphere 2 Dissolve S in absolute ethanol, add 80.00 parts of nano-attapulgite to soak fully, heat to 90°C under argon atmosphere, remove solvent ethanol, and obtain nano-attapulgite composite material coated with lithium sulfide;

[0058] Step 2: In terms of molar fractions, under an argon atmosphere, the nano-attapulgite composite material coated with lithium sulfide obtained in step 1, 30 parts of P 2 S 5 , 3 parts of LiBr, put them into a bowl made of zirconia together with zirconia balls, seal the bowl under an argon atmosphere, install the bowl on a ball mill, rotate at a speed of 300r / min, and mix for 30h to obtain sufficient After mixing the A system, add the mixed powder of the A system into a quartz tube, heat it after vacuum sealing, the heating temperature is 300 °C, and the heating time is 6 h to obtain a comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com