Power lead storage battery

A lead-acid battery, power-type technology, applied to lead-acid batteries, lead-acid battery electrodes, battery electrodes, etc., can solve the problems of poor cost performance and short service life, reduce electrode polarization, reduce current density, and improve charging acceptance effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

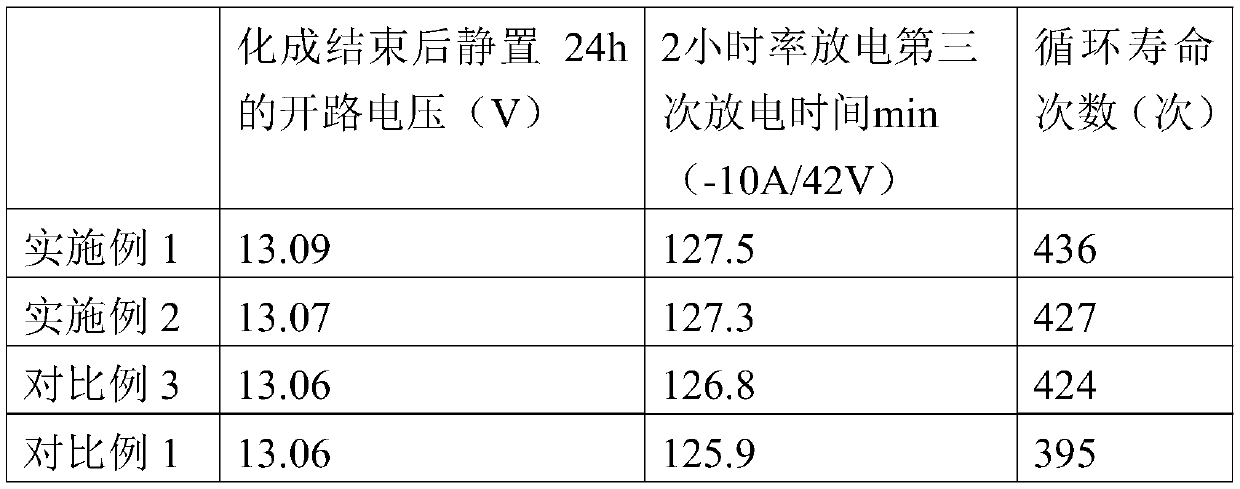

Examples

Embodiment 1

[0028] The formula of the positive lead paste is calculated by weight: 100 parts of lead powder (the content of lead oxide is 70% to 80%), 1 part of red lead, 15 parts of tetrabasic lead sulfate, high-purity graphene (purity not less than 99%) ) 0.5 parts, short fiber 0.3 parts, density 1.4g / ml sulfuric acid solution 8 parts, water 15 parts, titanium nitride 3 parts;

[0029] The preparation method of positive lead paste:

[0030] (1) uniformly mixing tetrabasic lead sulfate, high-purity graphene, short fibers and titanium nitride to obtain a positive electrode additive mixture;

[0031] (2) Add the positive electrode additive mixture prepared in step (1) and lead powder and red lead into the paste machine and stir, and the stirring time is 10min to obtain the positive electrode mixed lead powder;

[0032] (3) Add water to the positive electrode mixed lead powder and stir for 10 minutes;

[0033] (4) Add sulfuric acid solution, stir while adding sulfuric acid solution, contr...

Embodiment 2

[0043] The formula of the positive lead paste is calculated by weight: 100 parts of lead powder (the content of lead oxide is 70% to 80%), 5 parts of red lead, 10 parts of tetrabasic lead sulfate, high-purity graphene (purity not less than 99% ) 0.8 parts, 0.2 parts of short fibers, 12 parts of sulfuric acid solution with a density of 1.4 g / ml, 12 parts of water, and 2 parts of titanium nitride;

[0044] The preparation method of positive lead paste:

[0045] (1) uniformly mixing tetrabasic lead sulfate, high-purity graphene, short fibers and titanium nitride to obtain a positive electrode additive mixture;

[0046] (2) Add the positive electrode additive mixture prepared by step (1) and lead powder and red lead into the paste machine and stir, and the stirring time is 5min to obtain the positive electrode mixed lead powder;

[0047] (3) Add water to the positive electrode mixed lead powder and stir for 20 minutes;

[0048](4) Add sulfuric acid solution, stir while adding su...

Embodiment 3

[0058] The formula of the positive lead paste is calculated by weight: 100 parts of lead powder (the content of lead oxide is 70% to 80%), 10 parts of red lead, 5 parts of tetrabasic lead sulfate, high-purity graphene (purity not less than 99%) ) 1 part, 0.1 part of short fiber, 15 parts of sulfuric acid solution with a density of 1.4 g / ml, 10 parts of water, and 1 part of titanium nitride;

[0059] The preparation method of positive lead paste:

[0060] (1) uniformly mixing tetrabasic lead sulfate, high-purity graphene, short fibers and titanium nitride to obtain a positive electrode additive mixture;

[0061] (2) Add the positive electrode additive mixture prepared in step (1) and lead powder and red lead into the paste machine and stir, and the stirring time is 10min to obtain the positive electrode mixed lead powder;

[0062] (3) Add water to the positive electrode mixed lead powder and stir for 10 minutes;

[0063] (4) Add sulfuric acid solution, stir while adding sulfu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com