Silicon/carbon composite material and preparation method thereof

A carbon composite material and composite technology, which is applied in electrical components, battery electrodes, circuits, etc., can solve the problems of inability to maintain the original morphology of reaction precursors, speed up the electrochemical reaction speed, and volatile loss of chloride salts. The effect of improving electrochemical cycle stability, controllable product morphology, and facilitating large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

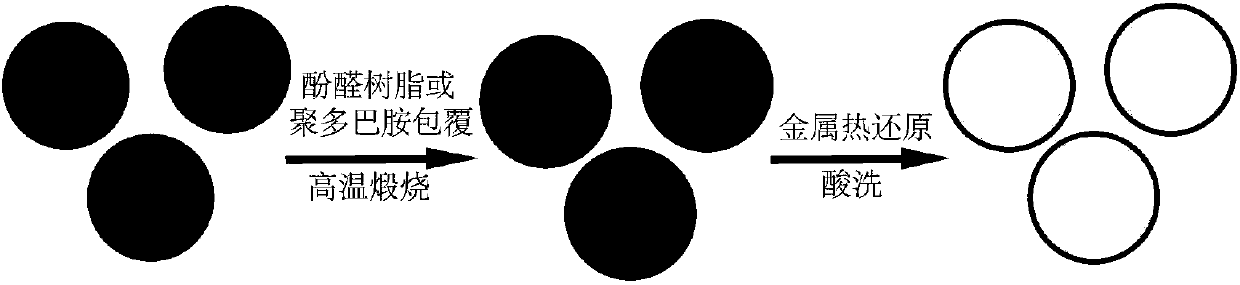

[0040] The method for preparing the silicon / carbon composite material in this embodiment specifically includes the following steps (see figure 1 ):

[0041] (1) Heating the precursor of silicon dioxide / carbon to 1000°C and carbonizing it for 2 hours in a nitrogen atmosphere to obtain a composite of silicon dioxide / carbon (carbon-coated or carbon-composite silicon dioxide);

[0042] Among them, the precursor of silica / carbon is diatomite powder coated with polydopamine, the concentration of dopamine in Tris-buffer buffer (PH, 8.5) is 4mg / ml, and the coating time is 5h.

[0043] (2) After mixing the silica / carbon compound obtained in step (1) with a reducing agent and a chloride salt system, place it in a reactor for reaction, and obtain the product after cooling down;

[0044] Among them, the reducing agent is aluminum powder, the mass ratio of aluminum powder and silica / carbon composite is 0.7:1, and the sum of the mass of aluminum powder and silica / carbon composite accounts ...

Embodiment 2

[0054] The method for preparing a silicon / carbon composite material in this embodiment specifically includes the following steps:

[0055] (1) Heat the precursor of silicon dioxide / carbon to carbonize at 700°C for 5 hours in a nitrogen atmosphere to obtain a composite of silicon dioxide / carbon (carbon-coated or carbon-composite silicon dioxide);

[0056] Wherein, the precursor of silica / carbon is diatomite powder coated with polydopamine, the concentration of dopamine in Tris-buffer (PH, 8.5) is 1 mg / ml, and the coating time is 20 h.

[0057] (2) After mixing the silica / carbon compound described in step (1) with the reducing agent and the chloride salt system, place it in a reactor for reaction, and obtain the product after cooling down;

[0058] Among them, the reducing agent is aluminum powder, the mass ratio of aluminum powder to the composite of silica / carbon is 1:1, and the sum of the mass of the composite of aluminum powder and silica / carbon accounts for 10% of the mass ...

Embodiment 3

[0062] The method for the conformal silicon / carbon composite material prepared in this embodiment specifically includes the following steps:

[0063] (1) Heat the precursor of silicon dioxide / carbon to carbonize at 800°C for 3 hours in a nitrogen atmosphere to obtain a silicon dioxide / carbon composite (carbon-coated or carbon-composite silicon dioxide);

[0064] Wherein, the precursor of silica / carbon is silica powder coated with polydopamine, the concentration of dopamine in Tris-buffer (PH, 8.5) is 2 mg / ml, and the coating time is 10 h.

[0065] (2) After mixing the silica / carbon compound described in step (1) with the reducing agent and the chloride salt system, place it in a reactor for reaction, and obtain the product after cooling down;

[0066] Among them, the reducing agent is aluminum powder, the mass ratio of aluminum powder and silica / carbon composite is 2:1, and the sum of the mass of aluminum powder and silica / carbon composite accounts for 40% of the mass of the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com