Preparation method and application of complex sodium ion battery negative material

A technology of sodium ion battery and negative electrode material, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of large volume expansion and poor conductivity, and achieve the effects of inhibiting volume expansion, improving electronic conductivity, and having a wide range of sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Weigh 4g of chlorella and 2g of stannous chloride and add them into 0.4L of deionized water, stir for 12 hours, centrifuge, wash the precipitate and dry it in an oven at 60°C;

[0034] 2) the light green solid gained in step 1) is ground to powder, mixed with the selenium powder of 12g, in H 2 / Ar (5% / 95%) atmosphere tube furnace, calcined at 400°C for 4 hours, and collected black solid samples, which were tin selenide-stannous selenide-chlorella-derived carbon composites;

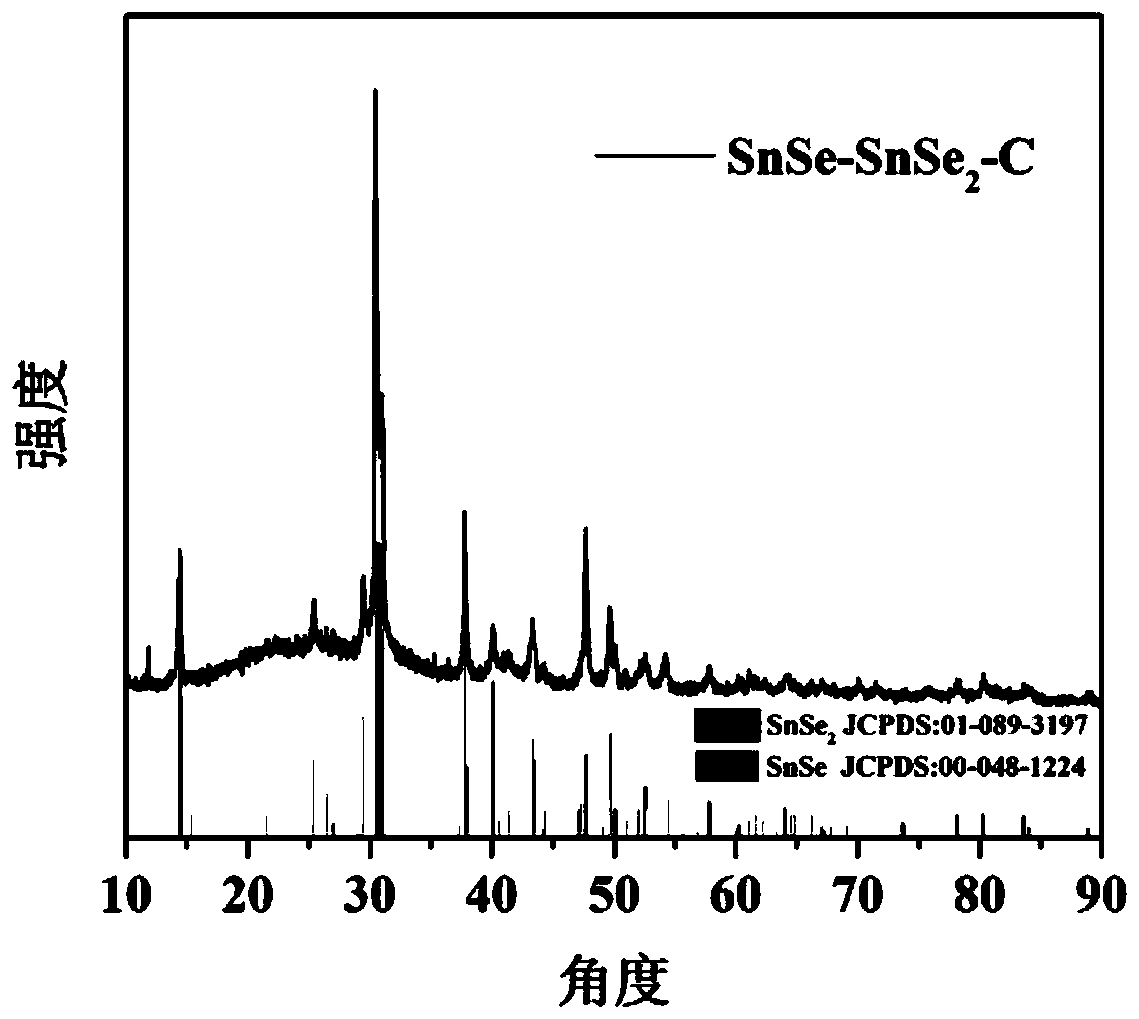

[0035] Carry out XRD to the tin selenide-stannous selenide-chlorella derived carbon complex prepared above, obtain the XRD pattern of tin selenide-stannous selenide-chlorella derived carbon complex, as figure 1 shown. From figure 1 It can be seen that the synthesized material is a mixed phase of tin selenide-snselenide two phases, and its diffraction peak position is consistent with the standard spectrum of tin selenide-snselenide (JCPDS, 089-3197; JCPDS, 048-1224) match.

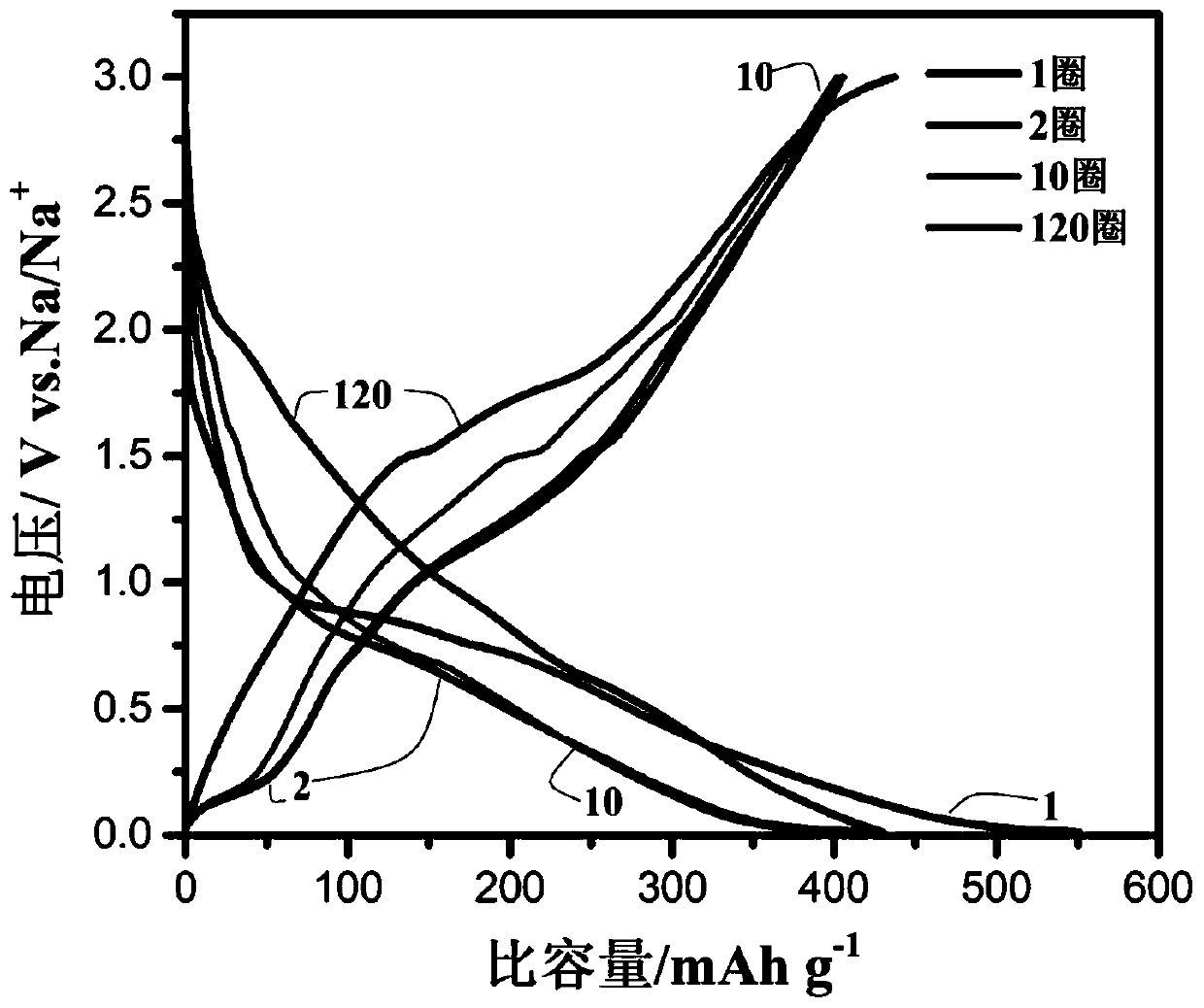

[0036] The above-p...

Embodiment 2

[0039] 1) Weigh 4g of chlorella and 4g of tin chloride and add them into 0.5L of deionized water, stir for 12 hours, centrifuge, wash the precipitate and dry it in an oven at 60°C;

[0040] 2) the light green solid gained in step 1) is ground to powder, mixed with the selenium powder of 20g, in H 2 / Ar (5% / 95%) atmosphere tube furnace, calcined at 700°C for 4 hours, and collected black solid samples, which were tin selenide-stannous selenide-chlorella-derived carbon complexes;

[0041] The tin selenide-stannous selenide-chlorella-derived carbon composite prepared in this example: the conductive agent super P carbon: the binder CMC is mixed and ground according to the mass percentage of 80:10:10 and evenly coated on the copper foil The top is used as the working electrode, the metal sodium sheet is the counter electrode and the reference electrode, and 1mol / L NaPF 6 / DIGLYME assembles button cells from the electrolyte; all assemblies are performed in an inert atmosphere glove ...

Embodiment 3

[0043] 1) Weigh 10g of chlorella and 5g of stannous sulfate into 0.8L of deionized water, stir for 24 hours, centrifuge, wash the precipitate and dry it in an oven at 80°C;

[0044] 2) step 1) gained light green solid is ground to powder, mixes with the selenium powder of 60g, in H 2 / Ar (5% / 95%) atmosphere tube furnace, calcined at 600° C. for 5 hours, and collected black solid samples, which were tin selenide-stannous selenide-chlorella-derived carbon complexes;

[0045] The tin selenide-stannous selenide-chlorella-derived carbon composite prepared in this example: the conductive agent super P carbon: the binder CMC is mixed and ground according to the mass percentage of 80:10:10 and evenly coated on the copper foil The top is used as the working electrode, the metal sodium sheet is the counter electrode and the reference electrode, and 1mol / L NaPF 6 / DIGLYME assembles button cells from the electrolyte; all assemblies are performed in an inert atmosphere glove box.

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com