Mg-Sn-Li-Zn magnesium alloy capable of double-stage aging strengthening and preparation method thereof

A mg-sn-li-zn, double-stage aging technology, which is applied in the field of non-ferrous metal materials and metallurgy, can solve the problems of no alloy structure description, etc., and achieve the effect of low alloy cost, good biocompatibility, and easy commercial use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1: Two-stage aging strengthening after extrusion deformation of Mg-Sn-Li-Zn alloy

[0045] The process route is as follows: casting→homogenizing heat treatment→extrusion→solid solution→quenching→first aging→second aging→finished material.

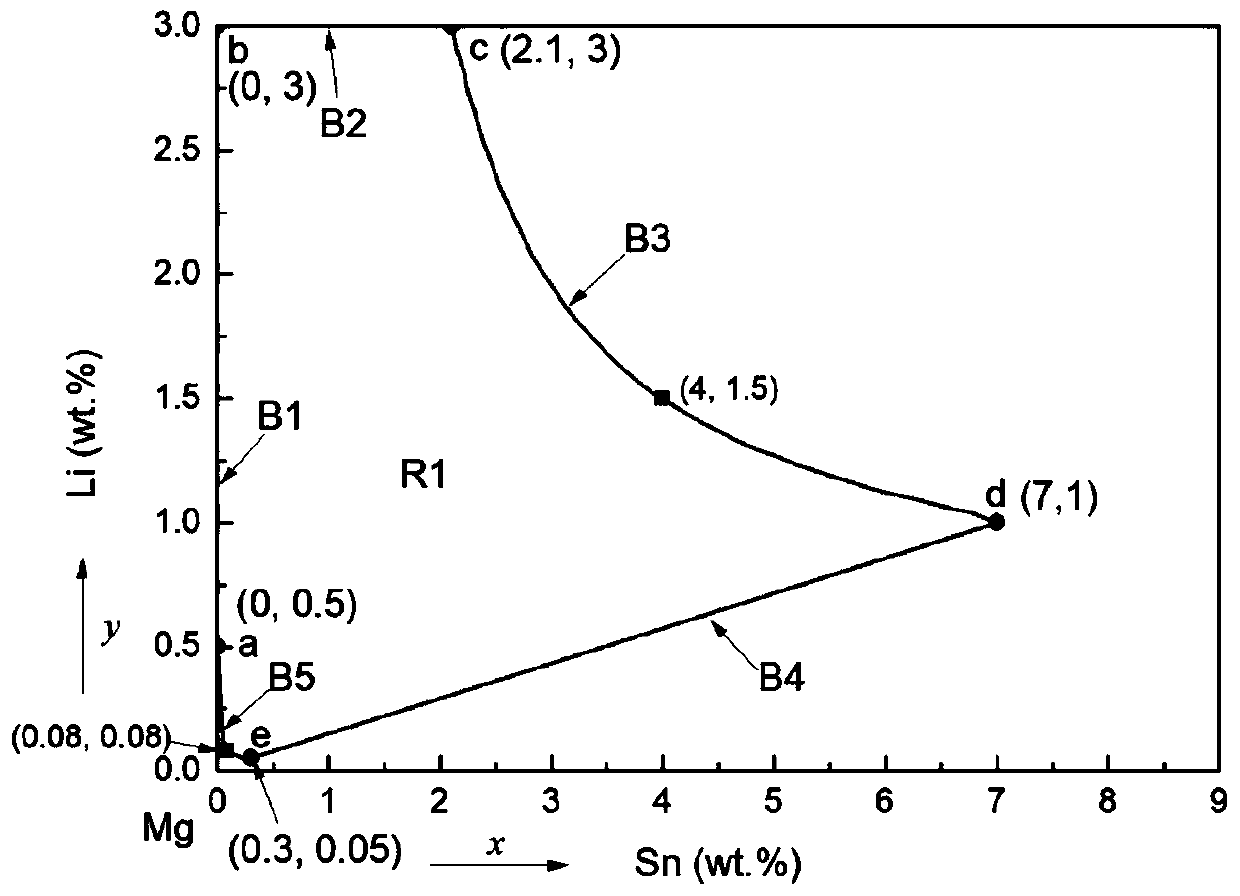

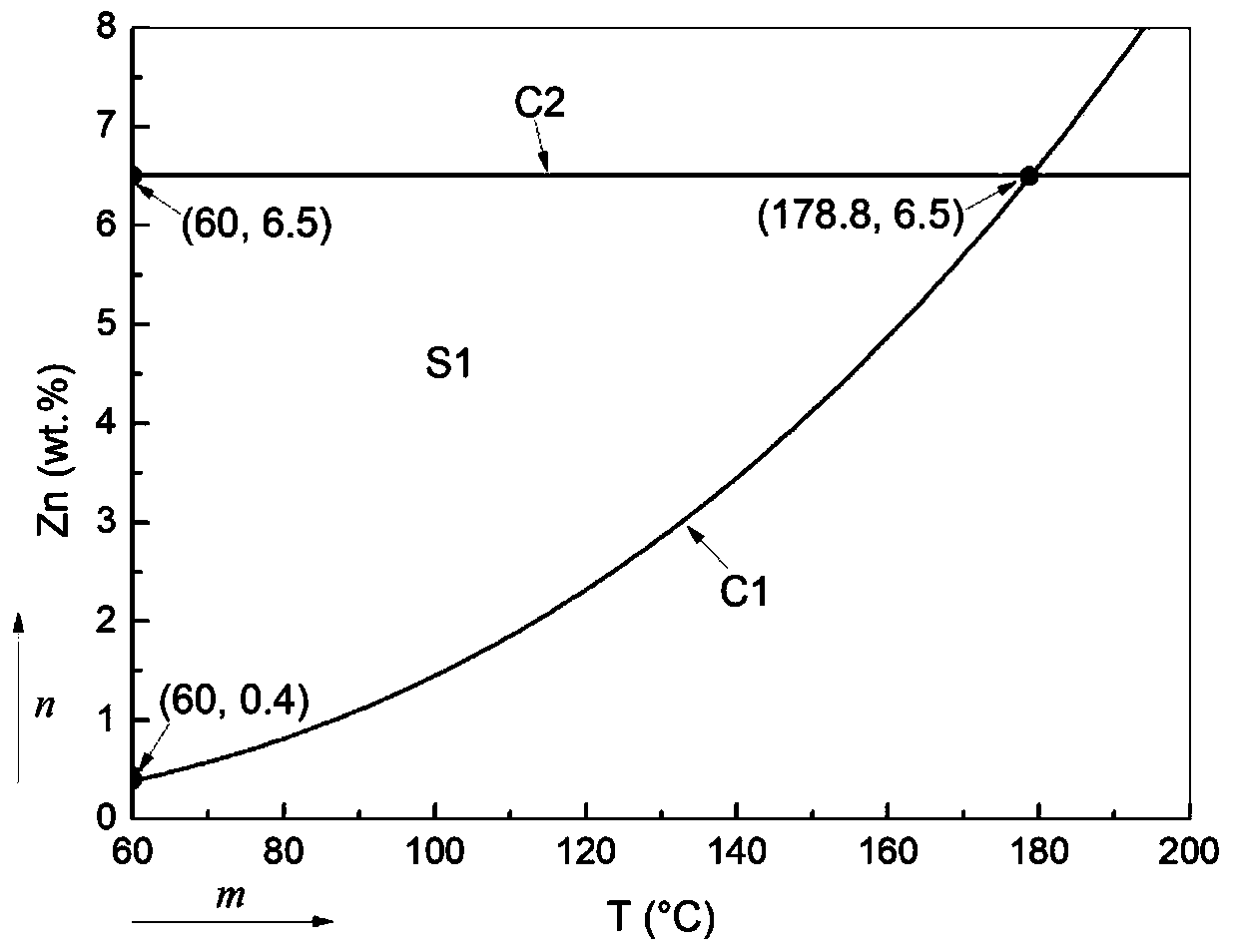

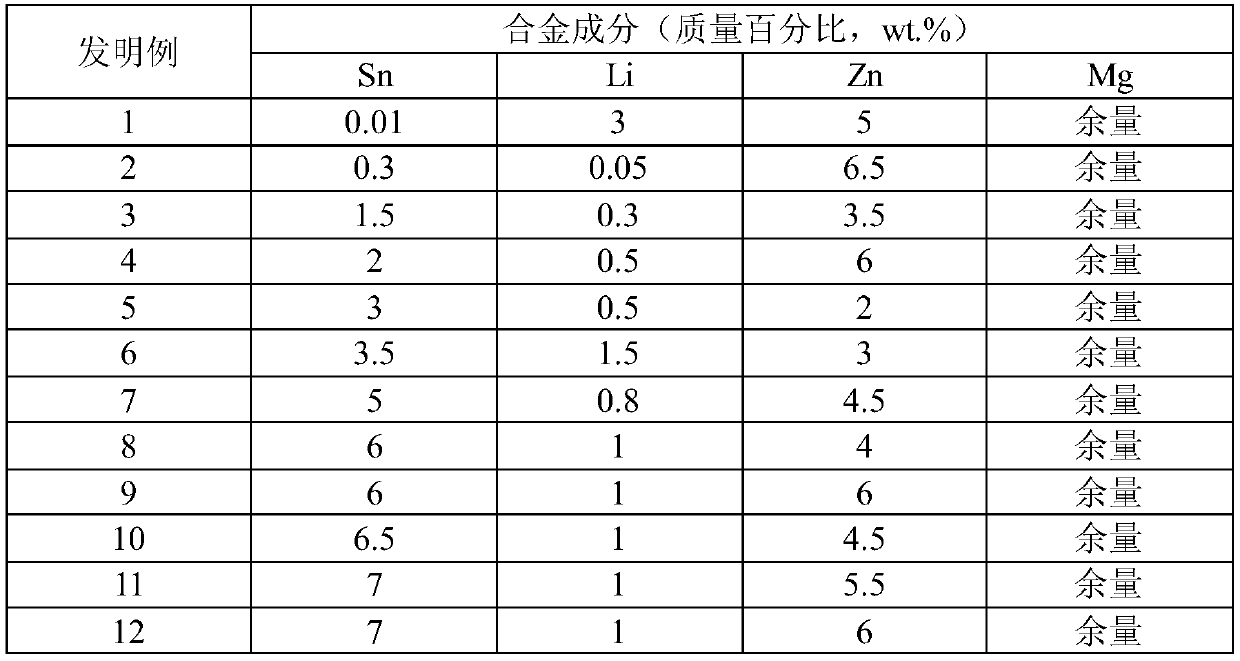

[0046] The composition of invention example alloy 1~12 is in figure 1 In partition R1 and figure 2 The central partition is in partition S1, as shown in Table 1-1. The invention example alloy was prepared from pure magnesium, Mg-Li master alloy and pure zinc as raw materials. Proportion the raw materials according to the ingredients in Table 1-1, put them into a vacuum induction furnace, vacuumize and fill with inert gas, then start to heat up, refine at 680-750°C for 5-15 minutes, cast, and cool to obtain a slab. Carry out homogenization heat treatment on the slab, and the process system is 300-600 ℃ for 1-48h. Then extruding is carried out, the extrusion temperature is 150-450° C., and the extrusion ratio is 10-40 to o...

Embodiment 2

[0051] Example 2: Mg-Sn-Li-Zn series multi-element magnesium alloy is rolled between two-stage aging

[0052] The process route is as follows: casting→homogenizing heat treatment→first-stage aging→rolling→second-stage aging→finished product.

[0053] The Mg-Sn-Li-Zn base alloy composition of invention example alloy 13~20 is in figure 1 into partition R1 and figure 2 In partition S1, as shown in Table 2-1. The representation of the alloy composition in Table 2-1 conforms to the international practice. Taking the inventive alloy 13 as an example, the contents of Sn, Li, Zn and Ca are 6%, 1%, 6% and 0.1% respectively. Except that Li was added in the form of Mg-Li master alloy, other elements were added in the form of pure substances. The alloy of the invention example is made into a slab according to Example 1 and subjected to homogenization heat treatment. Then carry out the first-stage aging, and keep warm at 60-100°C for 500-1000h. Then rolling is carried out, the proces...

Embodiment 3

[0058] Example 3: Double-stage aging strengthening of Mg-Sn-Li-Zn series multi-element magnesium alloy after rolling

[0059] The process route is as follows: casting→homogenizing heat treatment→rolling→solid solution→quenching→first-stage aging→second-stage aging→finished material.

[0060] The Mg-Sn-Li-Zn basic composition of the invention example alloy 21~30 is in figure 1 into partition R1 and figure 2In partition S1, as shown in Table 3-1. Except that Li was added in the form of Mg-Li master alloy, other elements were added in the form of pure substances. The alloy of the invention example is made into a slab according to Example 1 and subjected to homogenization heat treatment. Then rolling is carried out, the process system is 0-380°C, and the total deformation is 60-98%. Then carry out solid solution, keep warm at 400-600° C. for 10-30 minutes, and then quench in cold water to obtain Mg-based supersaturated solid solution. Then carry out the first stage of aging,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com