Temperature-resistant acid- and alkali-resistant organosilicone sealant and preparation method thereof

A sealant and silicone technology, applied in the field of sealants, can solve the problems of unsatisfactory heat resistance, low bonding strength, poor curing performance, etc., and achieve a simple and easy preparation method, suitable extrusion rate, and fast vulcanization speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

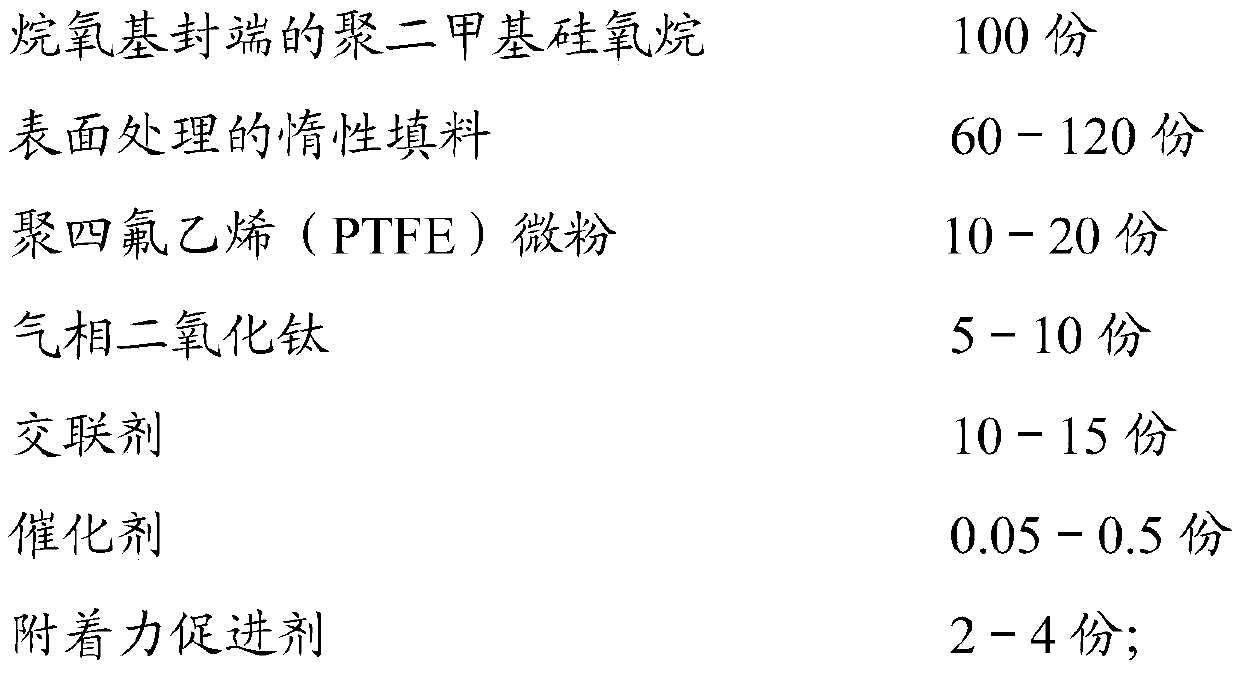

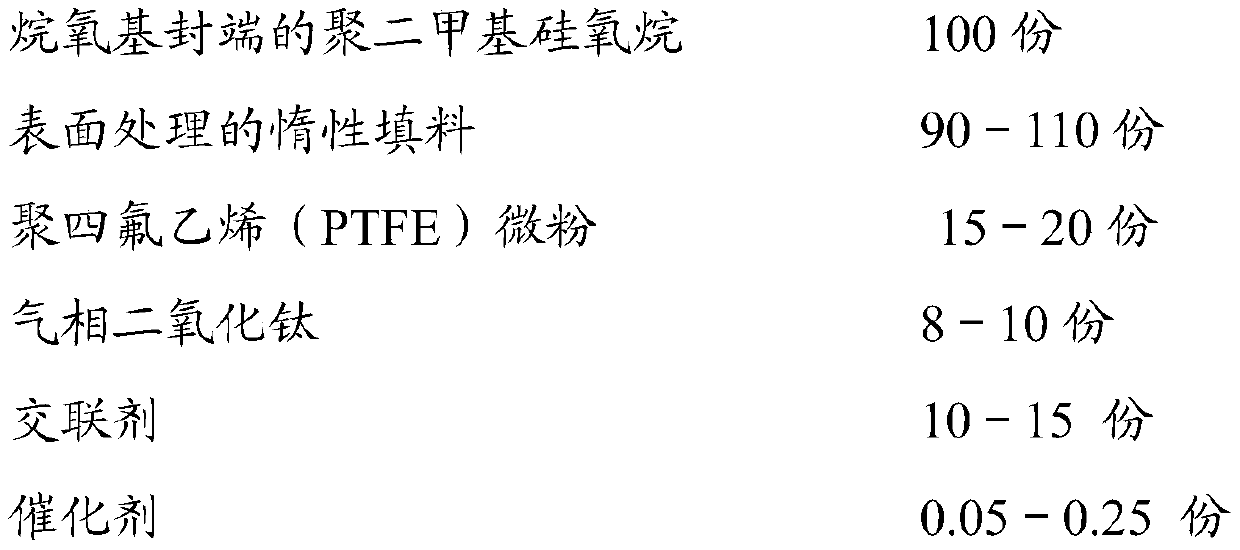

Method used

Image

Examples

Embodiment 1

[0046] The preparation method of a kind of temperature-resistant, acid and alkali-resistant silicone sealant of the present embodiment is as follows:

[0047](1) 100 parts by mass of alkoxy-terminated polydimethylsiloxane (kinematic viscosity at 25°C is 20 Pa·s) with the structure of formula (3), 60 parts by mass of methyl phenyl silicone resin surface treatment The precipitated barium sulfate (average particle size is 1.0 μm, the treatment method is: put the precipitated barium sulfate into a high-speed mixer with a blower device at the bottom, and then atomize and spray the isopropanol solution of methylphenyl silicone resin On the surface of the precipitated barium sulfate, the temperature was raised to 120° C. and heated and stirred for 60 min, and the isopropanol was evaporated to obtain a surface-treated precipitated barium sulfate with a methylphenyl silicone resin content of 1.8%. The average particle diameter of 12 parts by mass was 5 μm. Polytetrafluoroethylene (PTFE...

Embodiment 2

[0052] The preparation method of a temperature-resistant, acid and alkali-resistant silicone sealant of this embodiment is as follows:

[0053] (1) 100 parts by mass of alkoxy-terminated polydimethylsiloxane (kinematic viscosity at 25°C is 60 Pa·s) with the structure of formula (5), 60 parts by mass of methyl phenyl silicone resin surface treatment The quartz powder (average particle size is 2.0μm, the treatment method is: put the quartz powder into a high-speed mixer with a blower device at the bottom, and then atomize and spray the isopropanol solution of methylphenyl silicone resin on the quartz powder surface, heated up to 150°C and heated and stirred for 60min, and obtained surface-treated quartz powder with a methylphenyl silicone resin content of 0.8% after steaming off the isopropanol), 60 parts by mass of mica powder treated with methylphenyl silicone resin surface (The average particle size is 20 μm, and the treatment method is: drop the mica powder into a high-speed...

Embodiment 3

[0058] The preparation method of a temperature-resistant, acid and alkali-resistant silicone sealant of this embodiment is as follows:

[0059] (1) 100 parts by mass of alkoxy-terminated polydimethylsiloxane (with a kinematic viscosity of 20 Pa s at 25°C) having a structure such as formula (3), and 60 parts by mass of methylphenyl silicone resin surface treatment The quartz powder (average particle size is 1.5μm, the treatment method is: put the quartz powder into a high-speed mixer with a blower device at the bottom, and then atomize and spray the isopropanol solution of methylphenyl silicone resin on the quartz surface of the powder, heated to 130°C and stirred for 60min, evaporated the isopropanol to obtain a surface-treated quartz powder with a methylphenyl silicone resin content of 1.0%, 40 parts by mass of mica powder treated with a methylphenyl silicone resin surface (The average particle size is 12 μm, and the processing method is: drop the mica powder into a high-spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com