Modified filled polypropylene composite material with high fluidity, high modulus and high impact for automobile thinning and preparation method of material

A high-fluidity, composite material technology, applied in the field of polymer materials, can solve the problems of difficult preparation of nano-scale silica powder and porous silica microspheres, large influence on the appearance of parts, and limited application scope of materials, etc. Achieve the effect of excellent processing performance, simple processing and high impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

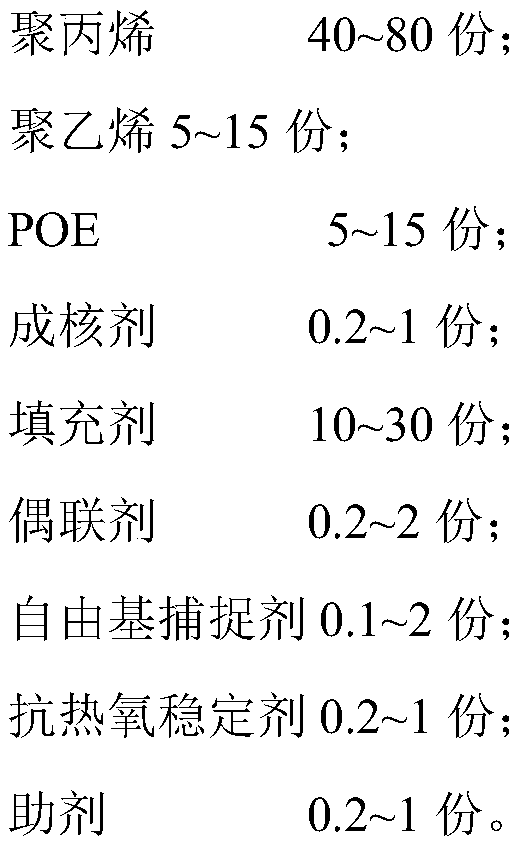

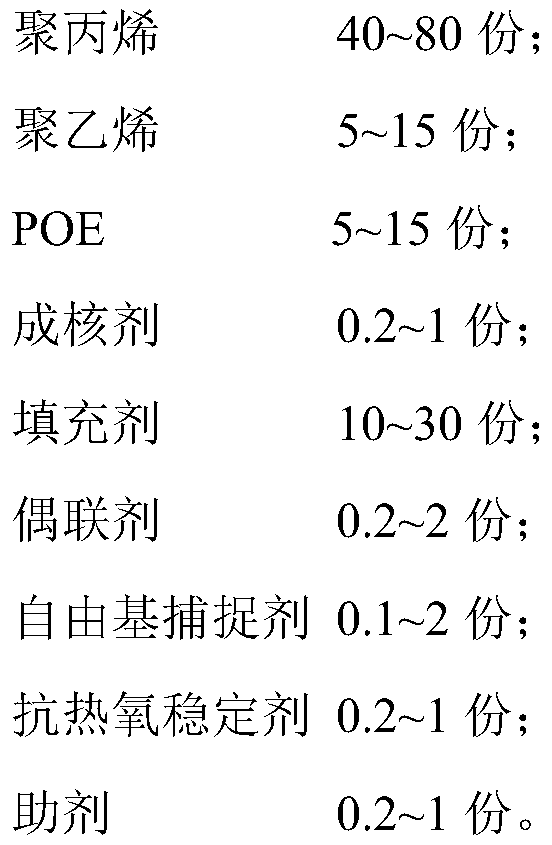

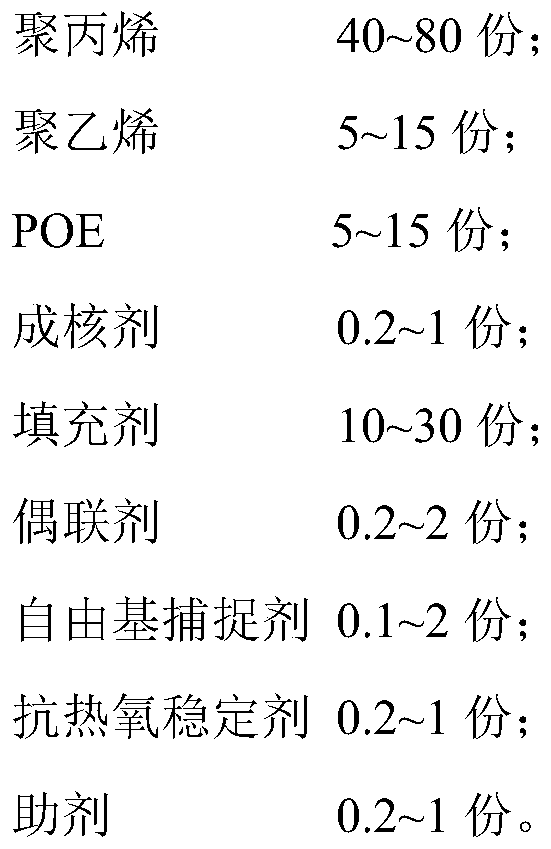

Method used

Image

Examples

preparation example Construction

[0048] The method for preparing a modified filled polypropylene composite material with high fluidity, high modulus and high impact for automobile thinning comprises the following steps:

[0049] 1) Weighing according to the aforementioned composition, first mix polypropylene, polyethylene and POE, then add nucleating agent, coupling agent, free radical scavenger, anti-thermal oxygen stabilizer and auxiliary agent to continue mixing to obtain a mixed material;

[0050] 2) Add the mixed material to the main feeding port of the twin-screw extruder, add the filler to the side feeding port of the twin-screw extruder, melt and mix it under a protective atmosphere, and then extrude it through the twin-screw extruder to produce Granules to obtain high fluidity, high modulus and high impact modified filled polypropylene composite materials for automobile thinning.

[0051] Preferably, in step 1) of the preparation method, the mixing is stirring and mixing in a mixer, specifically: fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com