A flexible red photoelectric injection light-emitting device based on metal halide perovskite light-emitting layer

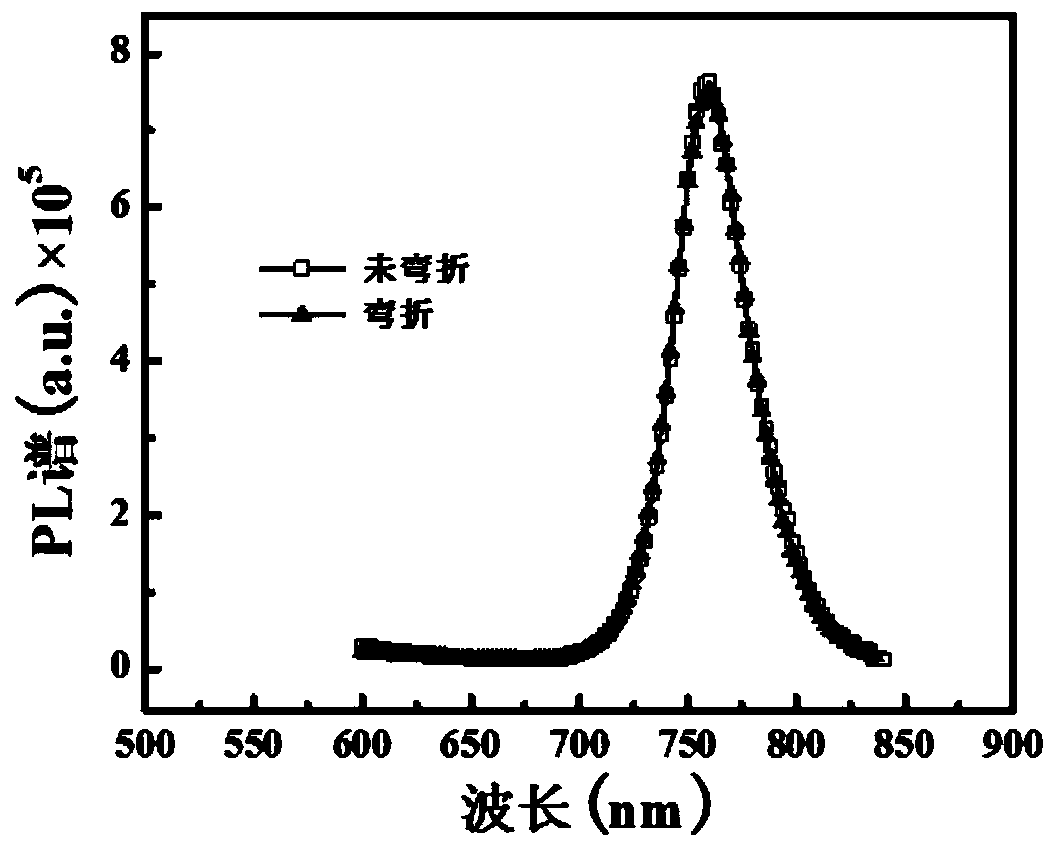

A metal halide and light-emitting device technology, which is applied in the field of flexible red photoelectric injection light-emitting devices, can solve problems such as poor bending stability, achieve good band gap matching, excellent mechanical bending durability, and solve bending stability problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] SnO 2 Preparation of sol-gel: weigh 2.79g SnCl 2 2H 2 O in 25mL of absolute ethanol, refluxed at 78°C for 3h, aged at 30°C for 3h, and then left at room temperature for 2d to obtain a light yellow sol, which is SnO 2 Sol.

[0029] Method of mixed perovskite precursors: The mixed perovskite precursors were prepared by a two-step method. A: First add 507.7mg PbI 2 , 80.7mg PbBr 2 , 172mg HC (NH 2 ) 2 I(FAI) and 22mg CH 3 NH 3 Br(MABr) was mixed with DMF (N,N dimethylformamide) and DMSO (dimethyl sulfoxide) (4:1, volume ratio) and dissolved in 1 mL of solvent. B: Dissolve 194.9 mg CsI in 500 uL DMSO. Both solutions were stirred at 60 °C for 1 h, and then Precursor B was added to Precursor A with a volume ratio of 1:19. The mixed precursor was stirred at 60 °C for 1 h.

[0030] Spiro-OMeTAD solution preparation method: Weigh 80mg of the hole transport material Spiro-OMeTAD (CuPc-DMP), 20uL Li-TFSI (520mg / 1mL acetonitrile), 30uLTBP, 20uL Co salt acetonitrile solu...

Embodiment 2

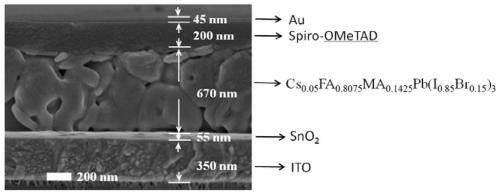

[0032] This embodiment discloses a flexible red photoelectric injection light-emitting device based on a metal halide perovskite light-emitting layer, and its preparation steps are as follows:

[0033] The substrate is flexible and bendable PEN / ITO with a layer of ITO on the surface. Adopt the SnO that embodiment 1 prepares 2 Sol-gel, mixed perovskite precursor and Spiro-OMeTAD solution.

[0034] (1) Before preparing the electron transport layer, first tape the 2.5×2.5cm 2 The flexible and bendable PEN / ITO substrate with a layer of ITO on the surface is selectively covered, etched with zinc powder and 2M dilute hydrochloric acid, and then wiped off the residual zinc powder with cotton. Ultrasonic cleaning with detergent, ultrapure water, acetone, and ethanol for 30 min respectively. After the washed glass is blown dry, treat it with UV-ozone cleaning equipment for 60 minutes, and store it in a dust-free environment for later use.

[0035] (2) Preparation of amorphous disco...

Embodiment 3

[0041] This embodiment discloses a flexible red photoelectric injection light-emitting device based on a metal halide perovskite light-emitting layer, and its preparation steps are as follows:

[0042] The substrate is flexible and bendable PEN / ITO with a layer of ITO on the surface. Adopt the SnO that embodiment 1 prepares 2 Sol-gel, mixed perovskite precursor and Spiro-OMeTAD solution.

[0043] (1) Before preparing the electron transport layer, first tape the 2.5×2.5cm 2 The flexible and bendable PEN / ITO substrate with a layer of ITO on the surface is selectively covered, etched with zinc powder and 2M dilute hydrochloric acid, and then wiped off the residual zinc powder with cotton. Ultrasonic cleaning with detergent, ultrapure water, acetone, and ethanol for 30 min respectively. After the washed glass is blown dry, treat it with UV-ozone cleaning equipment for 60 minutes, and store it in a dust-free environment for later use.

[0044] (2) Preparation of amorphous disco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com