Graphene/ceramics composite dielectric film applied to capacitor and preparation method for graphene/ceramics composite dielectric film

A technology of dielectric film and graphene, which is applied in the direction of fixed capacitor dielectric and fixed capacitor parts, etc., can solve the problems of large dielectric loss, difficult processing of composite materials, high ceramic filling volume, etc., and achieve high dielectric constant, The effect of high energy density and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Preparation of CCTO@GO: Add CCTO to the graphene oxide dispersion, ultrasonically disperse for 30 minutes, stir for 2 hours, add 10% ammonium chloride aqueous solution drop by drop while stirring, continue stirring for 2 hours after the dropwise addition, and then clean , suction filtration, and repeated cleaning 3 times to obtain flocs, put them in an oven and dry at 100°C for 1 hour, and prepare copper calcium titanate (CCTO@GO) coated with graphene oxide on the surface;

[0047] Preparation of CCTO@rGO: Copper calcium titanate (CCTO@GO) coated with graphene oxide was put into a tube furnace and calcined at 600 °C for 3 h under the protection of nitrogen atmosphere to prepare graphene-coated titanium copper calcium oxide (CCTO@rGO).

[0048] Silane-modified CCTO@rGO: Add copper calcium titanate (CCTO@rGO) coated with graphene into the γ-aminopropyltriethoxysilane solution, mix and stir for 3 hours, wash with deionized water and ethanol, Suction filtration, repeated c...

Embodiment 2-5

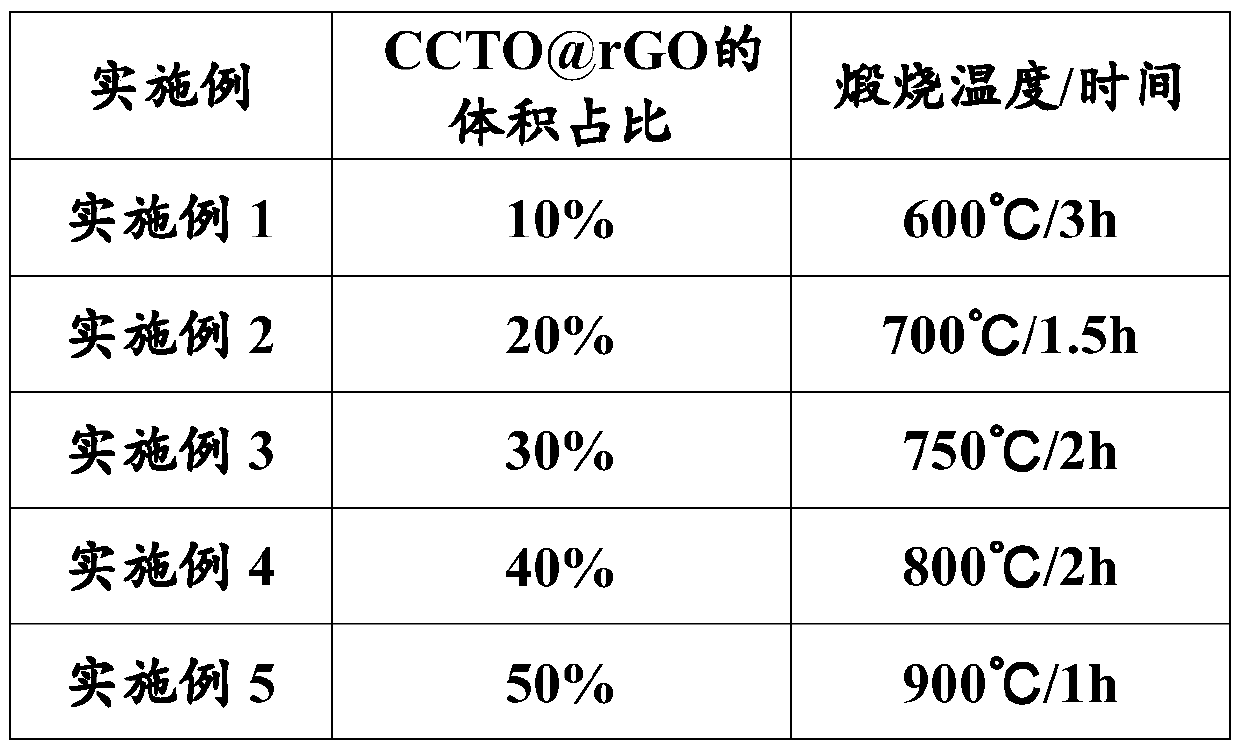

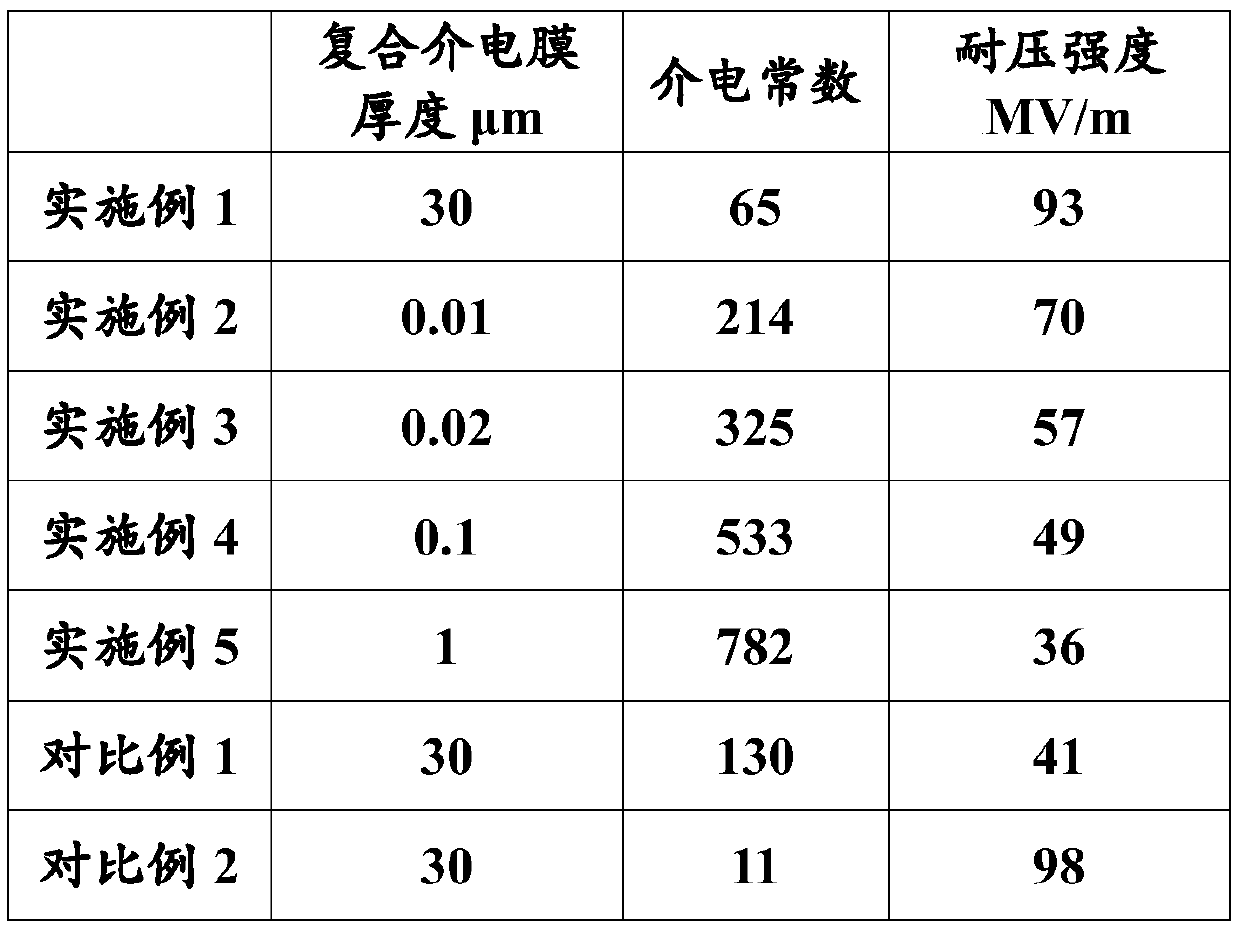

[0052] Its preparation process is the same as that of Example 1, the only difference being the different feed ratio, calcination temperature and calcination time. Specifically, the experimental conditions during the preparation of Examples 1-5 are shown in the table below.

[0053] Table 1 Example 1-5 experimental condition list

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com