Method for regulating thermoplasticity and toughness of redox-modified plant fiber and application of redox-modified plant fiber

A plant fiber, oxidation modification technology, applied in plant fiber, fiber treatment, fiber raw materials, etc., can solve the problems of high processing temperature, poor toughness, narrow processing temperature window, etc., to improve thermoplasticity and toughness, and good processing fluidity , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for regulating the thermoplasticity and toughness of redox modified plant fibers and a method for preparing materials, the specific steps are as follows:

[0041] (1) The sisal fiber is cut to 5 to 10 mm by a fiber cutter.

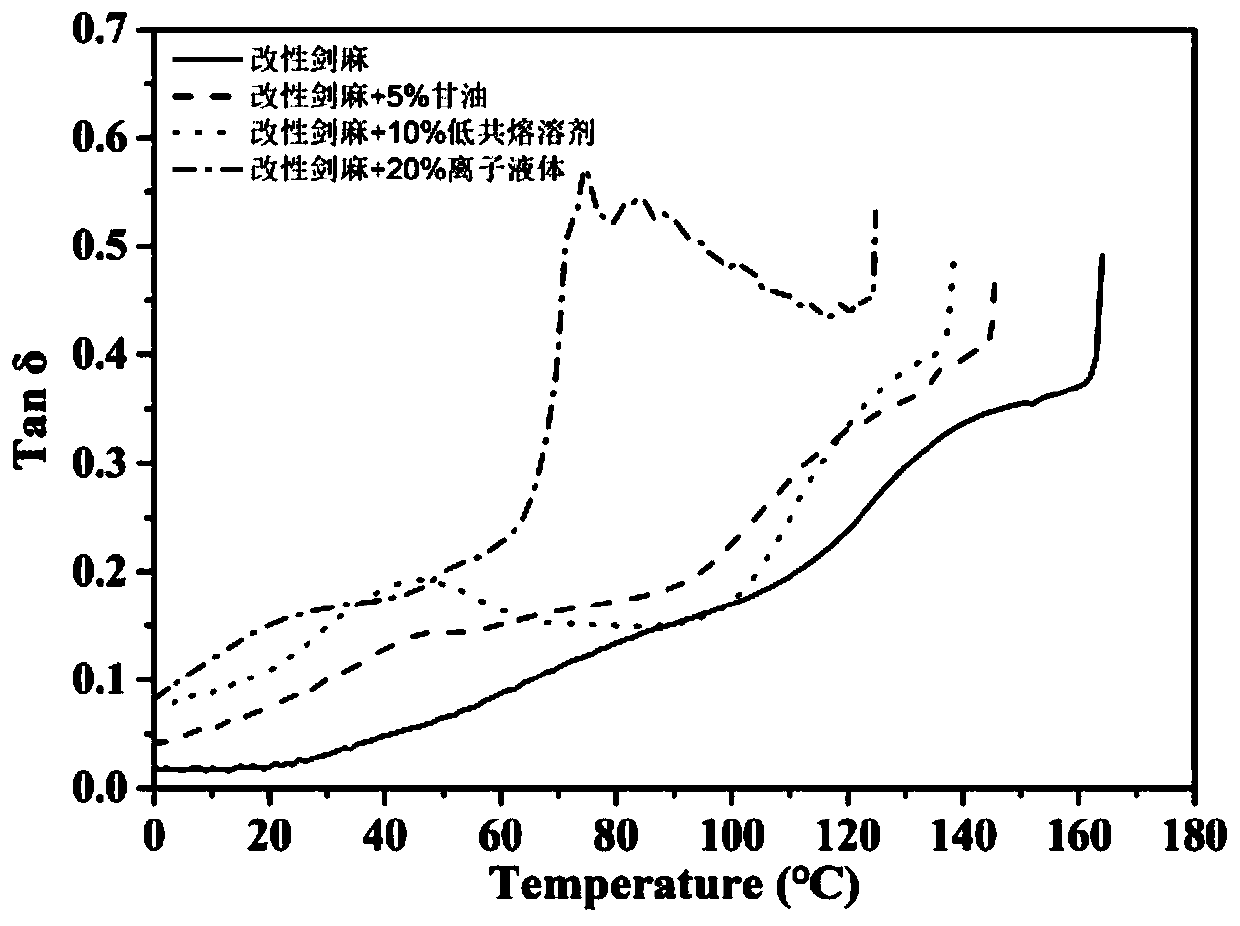

[0042] (2) Add sodium periodate and the cut sisal fiber described in step (1) in the aqueous solution at a weight ratio of 2:1, and configure a suspension with a sodium periodate concentration of 20g / L. Then, it was stirred and reacted at 60° C. in the dark for 4 hours, filtered and washed to obtain oxidatively modified sisal fibers.

[0043] (3) Sodium borohydride and the oxidation-modified sisal fiber described in step (2) are added into the aqueous solution at a weight ratio of 0.5:1, and configured into a suspension with a sodium borohydride concentration of 5 g / L. Stir the reaction at room temperature for 4 hours, filter and wash to obtain redox-modified sisal fiber.

[0044] (4) Glycerin is mixed with the oxidation-reduction modifie...

Embodiment 2

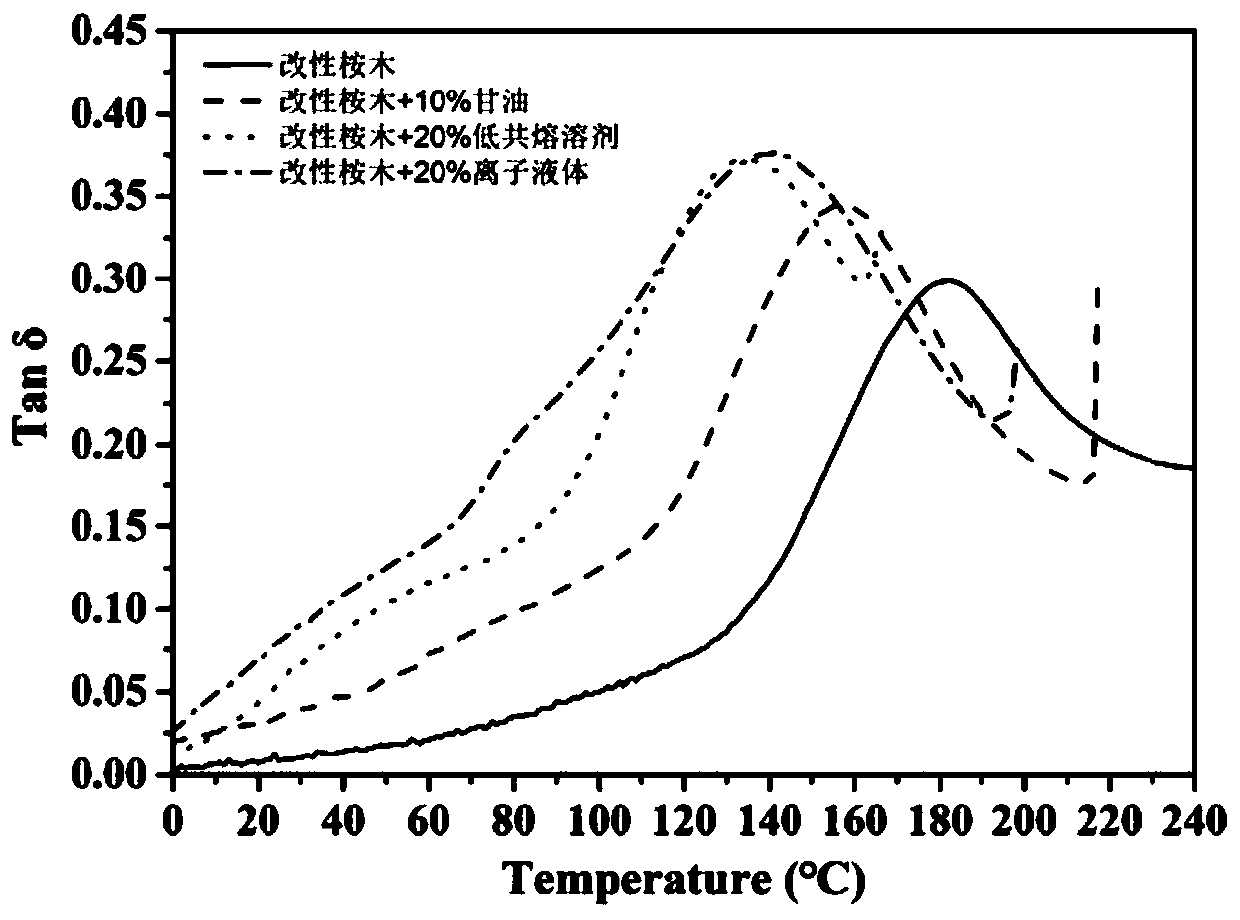

[0048] A method for regulating the thermoplasticity and toughness of redox modified plant fibers and a method for preparing materials, the specific steps are as follows:

[0049] (1) Cut the sisal fiber to 5-10 mm by a fiber cutting machine, and perform steam explosion pretreatment.

[0050] (2) the sisal fiber after the steam explosion pretreatment described in sodium periodate and step (1) is added in the aqueous solution with the weight ratio of 2:1, is configured into the suspension that sodium periodate concentration is 20g / L . Then, it was stirred and reacted at 60° C. in the dark for 4 hours, filtered and washed to obtain oxidation-modified steam-exploded sisal fibers.

[0051] (3) Sodium borohydride and the oxidation-modified steam-exploded sisal fiber described in step (2) were added into the aqueous solution in a weight ratio of 0.5:1, and a suspension with a sodium borohydride concentration of 5 g / L was configured. Stir the reaction at room temperature for 4 hours...

Embodiment 3

[0056] A method for regulating the thermoplasticity and toughness of redox modified plant fibers and a method for preparing materials, the specific steps are as follows:

[0057] (1) Cut the sisal fiber to 5-10 mm by a fiber cutting machine, and perform steam explosion pretreatment.

[0058] (2) the sisal fiber after the steam explosion pretreatment described in sodium periodate and step (1) is added in the aqueous solution with the weight ratio of 2:1, is configured into the suspension that sodium periodate concentration is 20g / L . Then, it was stirred and reacted at 60° C. in the dark for 4 hours, filtered and washed to obtain oxidation-modified steam-exploded sisal fibers.

[0059] (3) Sodium borohydride and the oxidation-modified steam-exploded sisal fiber described in step (2) were added into the aqueous solution in a weight ratio of 0.5:1, and a suspension with a sodium borohydride concentration of 5 g / L was configured. Stir the reaction at room temperature for 4 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com