Novel electrode slice and preparation method thereof, and solid-state battery equipped with the same

An electrode sheet, a new type of technology, applied in the direction of electrode manufacturing, battery electrodes, secondary batteries, etc., can solve problems such as easy to break, cannot change the diaphragm, and has no protective effect, so as to reduce the probability of spontaneous combustion and improve safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

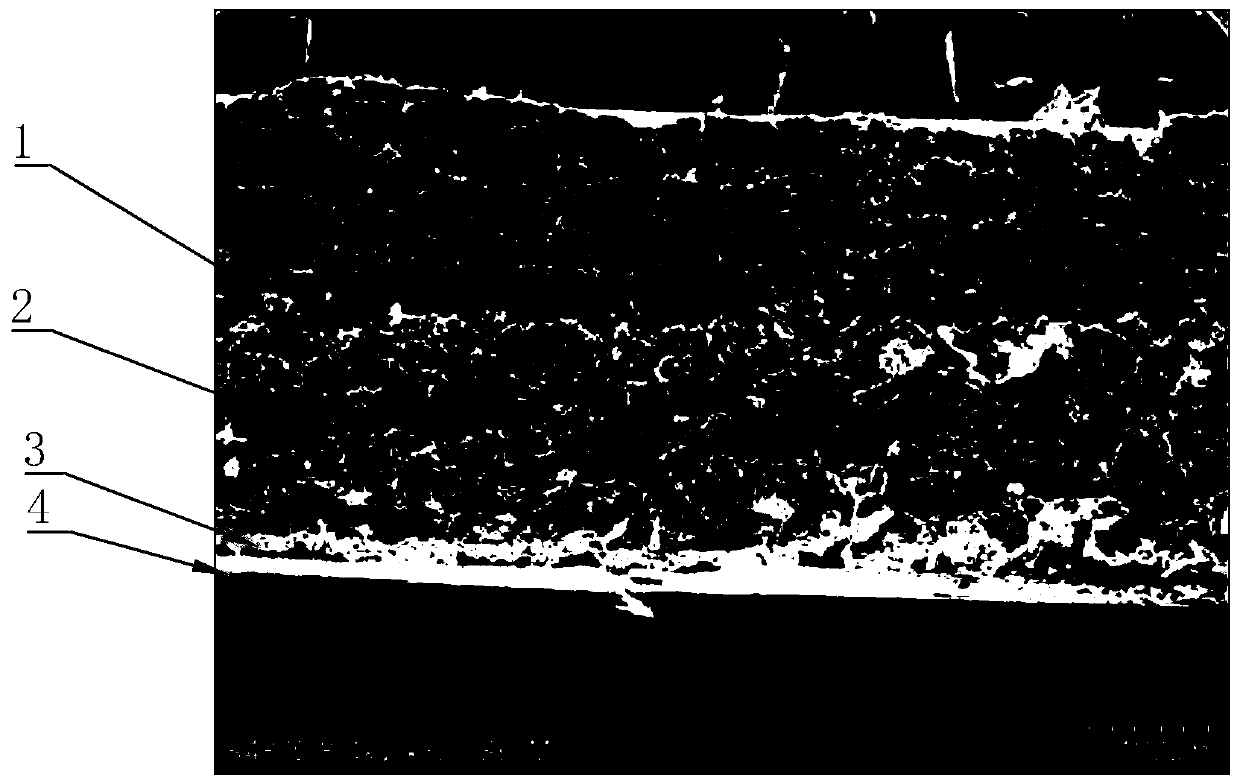

Image

Examples

Embodiment 1

[0034] A preparation method of a novel negative plate, comprising the following steps:

[0035] Step 1, preparation of coating 1 and 2 slurry:

[0036]Weigh the powder CMC and SBR of negative electrode active material natural graphite, conductivity agent SuperP, binder, wherein, mass ratio natural graphite: SP: CMC: SBR=94: 1: 1: 1, first dissolve CMC with deionized water, Then add natural graphite and SP respectively, and finally add SBR. When these components are completely dispersed, add deionized water to adjust the solid content of the slurry to 40%, and finally carry out vacuum degassing for 4 hours to complete the coating-2 slurry preparation of

[0037] Step 2, preparation of coating 2 and 3 slurry:

[0038] a. mix NMP and DMP with mass ratio m(NMP):m(DMF)=1:1, thereby complete the preparation of mixed solvent one;

[0039] b. Stir the mixed solvent 1 at a speed of 500-1000rpm, and add PVDF powder at a constant speed according to the mass ratio m(mixed solvent 1):m(...

Embodiment 2

[0055] A method for preparing a novel positive electrode sheet, comprising the following steps:

[0056] Step 1, preparation of coating-slurry:

[0057] Weigh the powder cellulose acetate butyrate and cyanoethyl sucrose of positive electrode active material NCM, conductivity agent KS-15, binding agent, wherein, mass ratio NCM: KS-15: cellulose acetate butyrate: cyanoethyl sucrose= 48:1:1:1, first dissolve cyanoethyl sucrose with deionized water, then add NCM and KS-15 respectively, and finally add cellulose acetate butyrate, when these components are completely dispersed, add deionized water, Adjust the solid content of the slurry to 50%, and finally perform vacuum degassing for 4 hours, thereby completing the preparation of the coating-slurry;

[0058] Step 2, preparation of coating 2 slurry:

[0059] a. mix DMAc and acetone with mass ratio m (DMAc): m (acetone)=1: 1, thereby complete the preparation of mixed solvent one;

[0060] b. Stir the mixed solvent 1 at a speed of ...

Embodiment 3

[0066] A preparation method of a novel negative plate, comprising the following steps:

[0067] Step 1, preparation of coating-slurry:

[0068] Weigh the powder PMMA and PVA of silicon-carbon material, conductivity agent Ketjen black, binder, wherein, mass ratio silicon-carbon material: Ketjen black: PMMA: PVA=95: 1.5: 1.5: 1.5, first use Dissolve PVA in deionized water, then add silicon carbon material and Ketjen black respectively, and finally add PMMA, when these components are completely dispersed, add deionized water, adjust the solid content of the slurry to 45%, and finally perform vacuum degassing for 4 hours , thereby completing the preparation of the coating-slurry;

[0069] Step 2, preparation of coating 3 slurry:

[0070] (1), in an environment with a dew point less than -20°C, mix DMAc and tetrahydrofuran with a mass ratio of m(tetrahydrofuran):m(DMAc)=1:1, thereby completing the preparation of the mixed solvent two;

[0071] (2), according to the mass ratio m ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com