Recipe design for enabling aluminum alloy spraying oil removal groove and chromate-free passivation groove chemical to be compatible

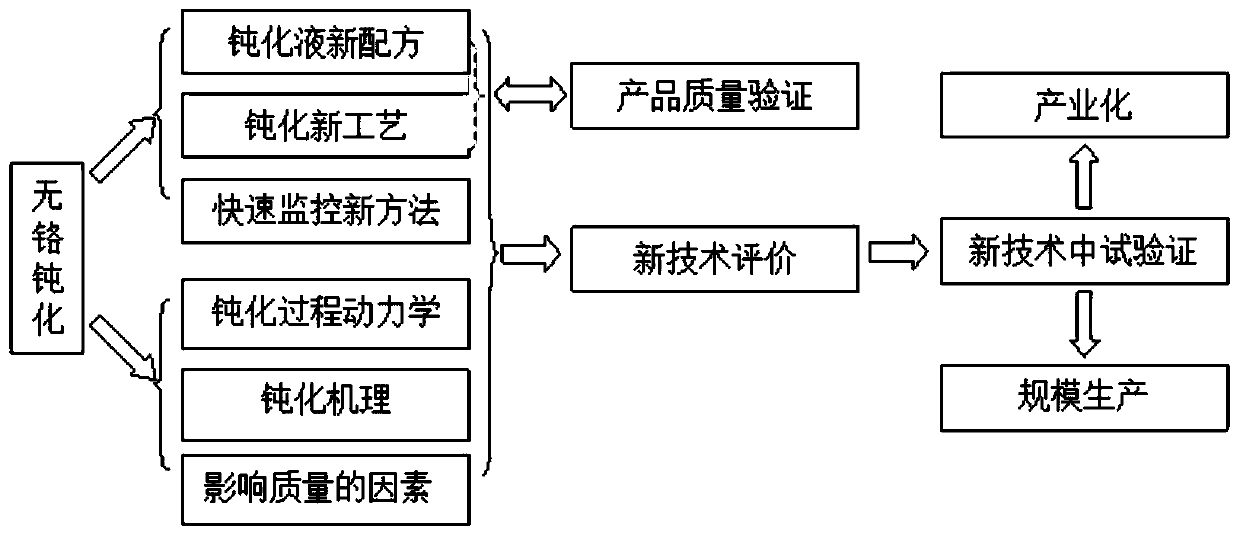

A chromium-free passivation agent and chromium-free passivation technology, applied in the direction of metal material coating process, can solve the problems of the toxic environment of rare earth inorganic salts, which cannot be effectively solved, volatilization pollution, etc., and achieve stable operation and increase stability. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0180] 2# flowing water washing tank, 3# flowing water washing tank, 5# flowing water washing tank, and 6# tank flowing water washing tank are washed with tap water for 60 seconds and dripped for 30 seconds for production.

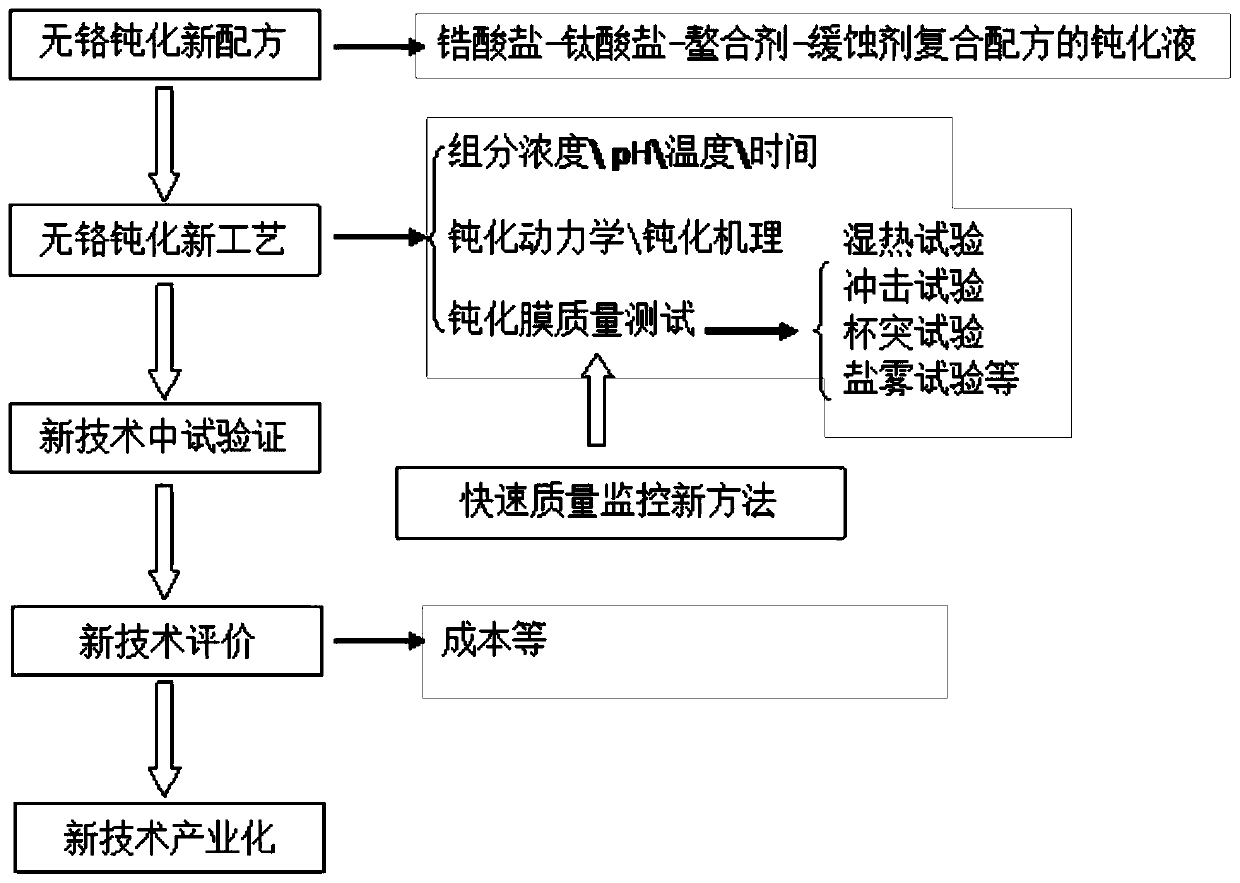

[0181] The aluminum alloy spraying degreasing tank of the present invention is designed to be compatible with chromium-free passivation tank agents, including 1# degreasing tank and 4# chrome-free passivating tank, and the aluminum alloy enters 4# chrome-free passivation after degreasing in 1# degreasing tank The tank is passivated, the 1# degreasing tank contains a degreasing agent, and the 4# chromium-free passivation tank contains a chromium-free passivating agent. 2# flowing water washing tank and 3# flowing water washing tank are located before 4# chrome-free passivation tank, 5# flowing water washing tank and 6# flowing water washing tank are located after 4# chrome-free passivation tank. The cleaning water in the cleaning tank is tap water.

[0182...

Embodiment 2

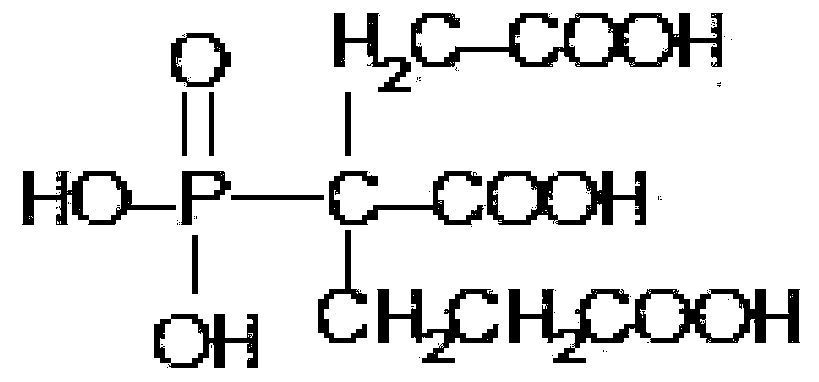

[0187] The aluminum alloy spray degreasing tank of the present embodiment is the same as embodiment 1 to the passivation line compatible with the chromium-free passivation tank medicament, and the difference is that the PBTCA concentration of 4# chromium-free passivation tank is increased to 4.5g / L, 4# , 5#, and 6# grooves are clearer, and the national standard inspection of spraying materials is qualified; reduce the PBTCA concentration of 4# chromium-free passivation tank to 2.0g / L, and the national standard inspection of spraying materials is qualified, 4# grooves are clear, and 5#, 6# grooves are slightly Turbid, with a small amount of fluoride separated out. It can not only meet the requirements of the national standard, reduce the cost, but also block the precipitation of fluoride in the 4# chromium-free passivation tank, 5#, and 6# washing tanks. %)): PBTCA (50wt.%)=1:1 (weight ratio, wherein the weight ratio of fluotitanic acid to fluozirconic acid is also 1:1); consid...

Embodiment 3

[0190] The passivation line compatible with the chromium-free passivation tank agent of the aluminum alloy spraying degreasing tank of this embodiment is the same as that of embodiment 1, the difference is that the passivation time of 4# chromium-free passivation tank is increased to 240 seconds, and the national standard test is qualified ;Reduce the passivation time of 4# chrome-free passivation tank to 20 seconds, and the national standard test occasionally fails; the passivation time can be shortened appropriately at room temperature, but not less than 30 seconds; the passivation time can be extended appropriately at low temperature, but not more than 240 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com