Pre-hardening type plastic die steel and preparation method thereof

A plastic mold steel, pre-hardened technology, applied in the field of metallurgical materials, can solve the problems of high pressure and corrosion, low transverse impact toughness, poor wear resistance, etc., achieve uniform and dense structure, improve transverse impact toughness, and improve hardenability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

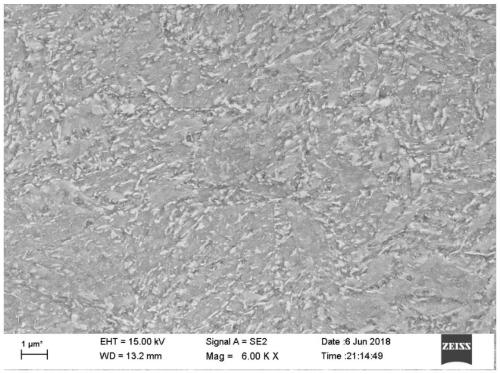

Embodiment 1

[0032] The molten steel is smelted by vacuum induction smelting, and then cast into a cylindrical steel ingot with a size of Φ100×200mm. The composition contains C 0.35%, Si 0.34%, Mn 1.30%, Cr 1.96%, Ni 0.91%, P0 .004%, S 0.003%, V 0.10%, the balance is Fe;

[0033] Preheat the steel ingot to 650°C for 3 hours, then heat it to 1250°C at a rate of 80°C / h for a holding time of 5 hours to obtain a heat-treated steel ingot;

[0034] The heat-treated steel ingot is forged, the initial forging temperature is 1200°C, the final forging temperature is 830°C, and then cooled to room temperature with the furnace to obtain the forged steel ingot; when forging, the upsetting ratio is 2.0, the elongation ratio is 2.2, and the total number of forging steps is 5 step;

[0035] Normalize the forged steel ingot first, the normalizing temperature is 880±10°C, and the time is 2h, to obtain the normalized steel ingot;

[0036] The normalized steel ingot is directly subjected to quenching treatm...

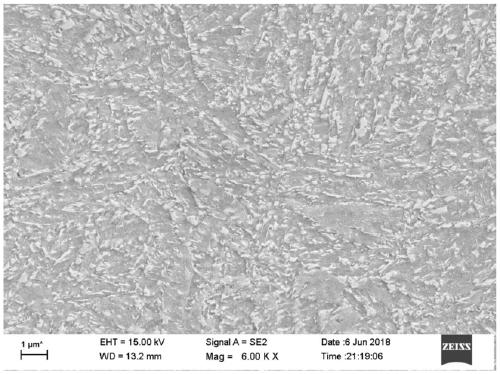

Embodiment 2

[0040] Method is with embodiment 1, and difference is:

[0041] (1) The size of the steel ingot is Φ102×195mm, and the composition contains C 0.32%, Si 0.32%, Mn 1.50%, Cr 2.03%, Ni 0.924%, P 0.005%, S 0.003%, V 0.33% by mass percentage;

[0042] (2) The steel ingot is heated to 700°C for 3 hours, then heated to 1200°C at a rate of 70°C / h, and the holding time is 8 hours;

[0043] (3) The initial forging temperature is 1180°C, and the final forging temperature is 810°C; the upsetting ratio during forging is 2.2, the drawing ratio is 4.0, and the total number of forging steps is 8;

[0044] (4) The normalizing temperature is 880±10°C, and the time is 2.5h;

[0045] (5) Heating to 940°C for 2 hours during quenching treatment;

[0046] (6) Tempering treatment at 550°C for 3 hours; the transverse impact energy of the center of the pre-hardened plastic mold steel is 14.0J, the transverse impact energy of the edge is 16.0J, the longitudinal impact energy of the center is 16.6J, an...

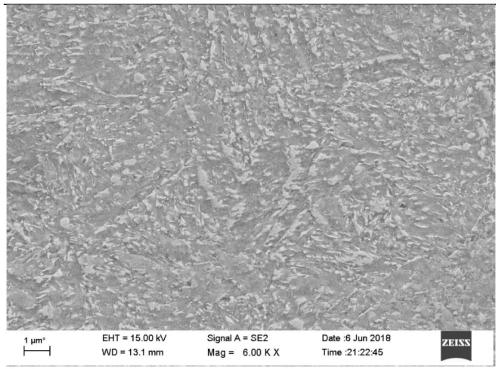

Embodiment 3

[0048] Method is with embodiment 1, and difference is:

[0049] (1) The size of the ingot is Φ95×195mm, and the composition contains C 0.36%, Si 0.28%, Mn 1.56%, Cr 2.07%, Ni 0.98%, P 0.004%, S 0.002%, V 0.24% by mass percentage;

[0050] (2) Preheat the steel ingot to 600°C for 4 hours, then heat it to 1230°C at a rate of 90°C / h, and hold for 6 hours;

[0051] (3) The initial forging temperature is 1190°C, and the final forging temperature is 820°C; when forging, the upsetting ratio is 1.8, the drawing ratio is 2.0, and the total number of forging steps is 10;

[0052] (4) The normalizing temperature is 880±10℃, and the time is 3h;

[0053] (5) Heating to 920°C for 2.5 hours during quenching treatment;

[0054] (6) Heat preservation at 510°C for 2 hours during tempering treatment; the transverse impact energy of the center of the pre-hardened plastic mold steel is 16.3J, the transverse impact energy of the edge is 18.1J, the longitudinal impact energy of the center is 19.4J...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average hardness | aaaaa | aaaaa |

| Average hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com