Silicone rubber composition, silicone rubber and preparation method of silicone rubber

A silicone rubber composition and raw rubber technology, applied in the field of silicone rubber, can solve the problems of increased curing time, long operating time, and poor controllability of silicone rubber compositions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

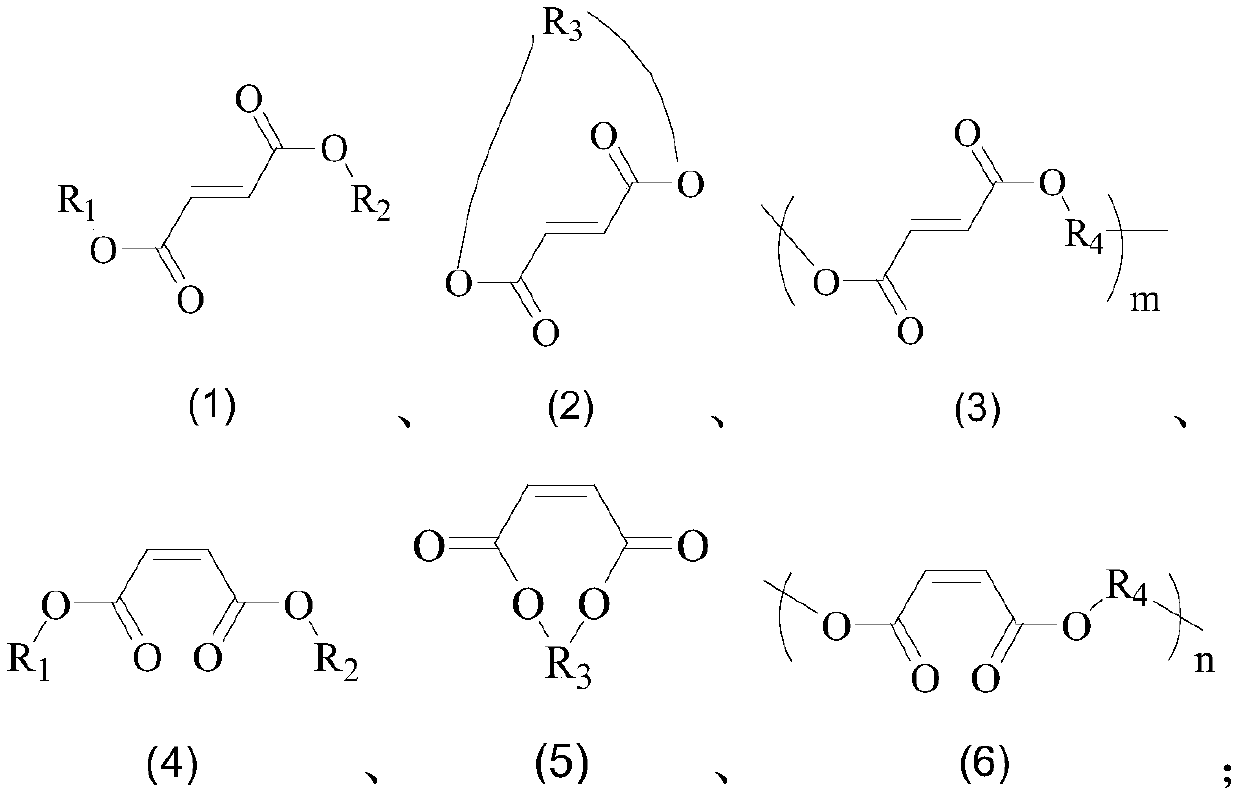

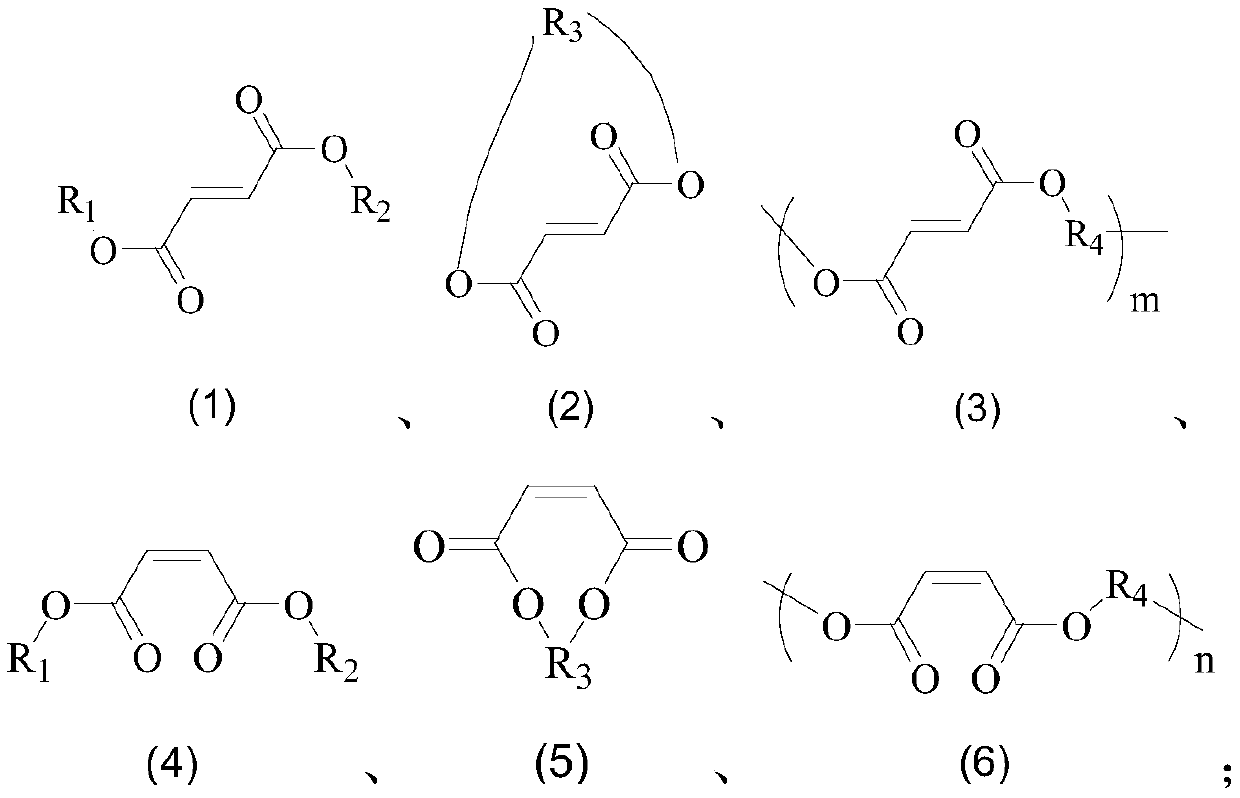

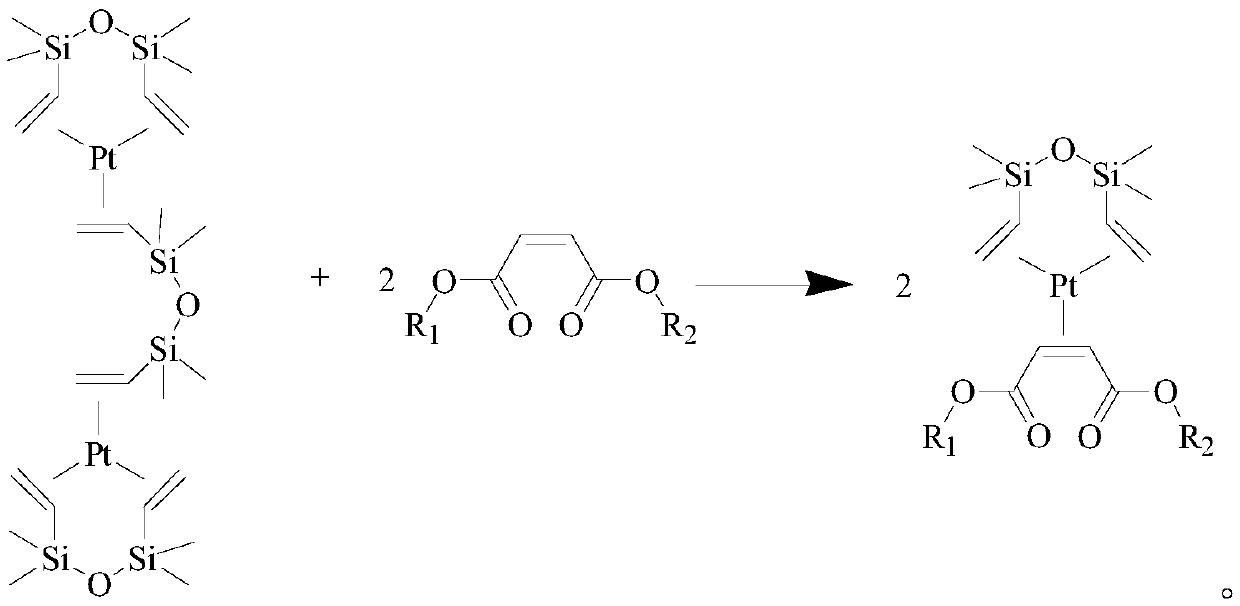

Method used

Image

Examples

preparation example Construction

[0069] The present invention also provides a preparation method of silicone rubber, comprising the following steps:

[0070] (1) provide the above-mentioned silicone rubber composition;

[0071] (2) heating the silicone rubber composition, under the catalysis of the noble metal catalyst, the raw rubber and the crosslinking agent undergo a curing reaction to obtain silicone rubber.

[0072] Specifically, the heating temperature in step (2) is greater than or equal to 50°C, preferably, the heating temperature is 50°C to 150°C, more preferably 60°C to 150°C.

[0073] The present invention also provides a silicone rubber obtained by the above preparation method, wherein the silicone rubber has a network structure.

[0074] The silicone rubber of the present invention has properties such as heat resistance, cold resistance, dielectric property, ozone resistance and atmospheric aging resistance, and can be used for a long time at -60°C to 250°C. Therefore, it can be widely used in ...

Embodiment 1

[0077] Preparation of long-chain branched fumarate (taking di-n-octyl fumarate as an example).

[0078] Dissolve 260g of n-octanol in 1000g of cyclohexane, add 110g of sodium carbonate and stir, place in a 2L three-necked glass flask, slowly add 160g of fumaric acid chloride dropwise, complete the dropwise addition in 30 minutes, slowly heat up to 50°C, and stir overnight . The precipitate was removed by filtration. The filtrate was washed three times with 200 mL and 5% aqueous sodium carbonate solution, three times with 200 mL water, and 200 mL saturated NaCl solution, dried over anhydrous magnesium sulfate, filtered, and the solvent was distilled off to obtain a crude product. Under reduced pressure distillation, 310 g of di-n-octyl fumarate was obtained, and the yield was 90%.

[0079] By this method, the corresponding long-chain branched fumaric acid diesters can be obtained by reacting different alcohols with fumaric acid chlorides.

[0080] For the reaction of fatty a...

Embodiment 2

[0082] Preparation of cyclic fumarate (take cyclic dodecyl fumarate as an example).

[0083]Dissolve 20 g of dodecyl glycol in 500 mL of cyclohexane, and dissolve 15.3 g of fumaric acid chloride in 500 mL of cyclohexane, respectively, place them in two 1000 mL round-bottomed flasks, mix 12 g of anhydrous sodium carbonate and 500 mL of cyclohexane. Placed in a 2L three-necked flask. At the same time, dodecyl glycol and fumaric acid chloride cyclohexane solution were added dropwise to the 2L round-bottomed flask, and the dropping rate was controlled at about 1 mL / min, and the dropping was completed in 8 hours. Continue stirring overnight. The precipitate was removed by filtration. The filtrate was washed three times with 200 mL and 5% aqueous sodium carbonate solution, three times with 200 mL water, and 200 mL saturated NaCl solution, dried over anhydrous magnesium sulfate, filtered, and the solvent was distilled off to obtain a crude product. Under reduced pressure distillat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com