Composition for preparing three-dimensional greening cultivation container and preparation method

A cultivation container and three-dimensional greening technology, applied in botany equipment and methods, container cultivation, horticulture, etc., can solve problems such as insufficient flexural and compressive strength, poor thermal insulation performance, and insufficient ornamental value, and achieve good physical and chemical properties, Solve the effects of poor thermal insulation performance, energy saving and simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

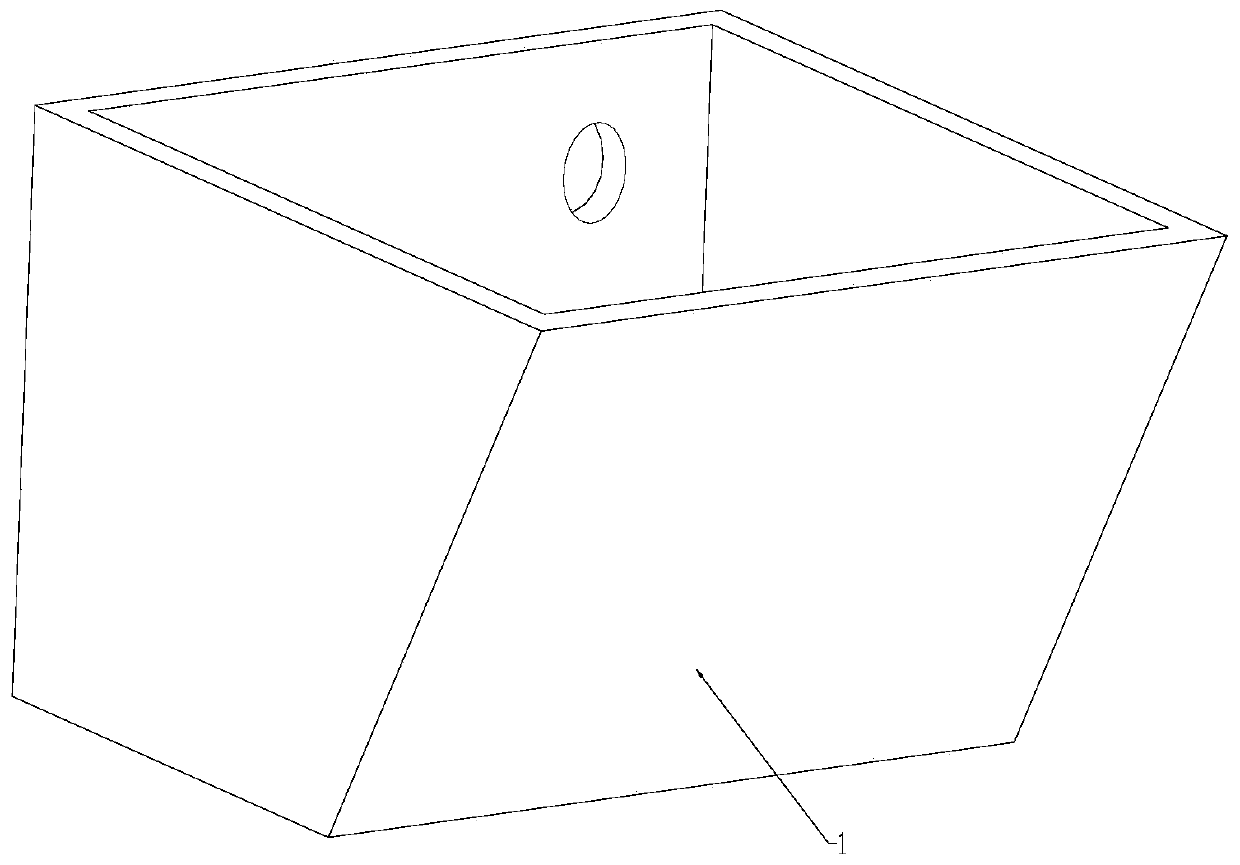

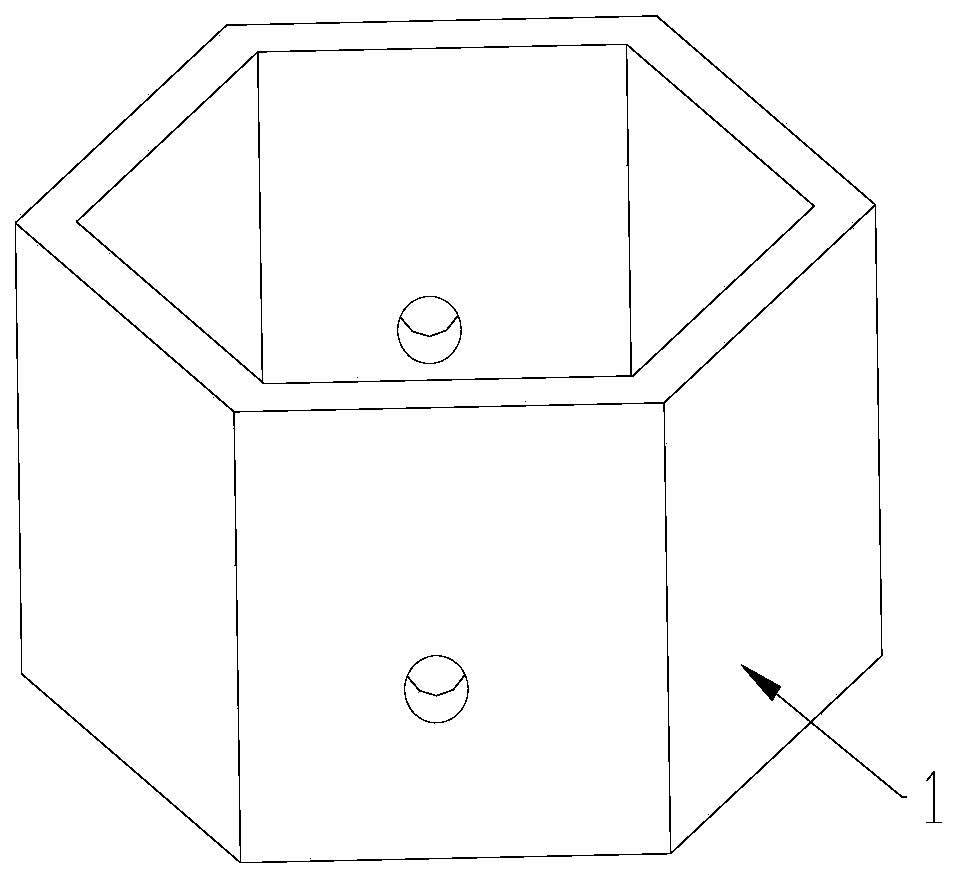

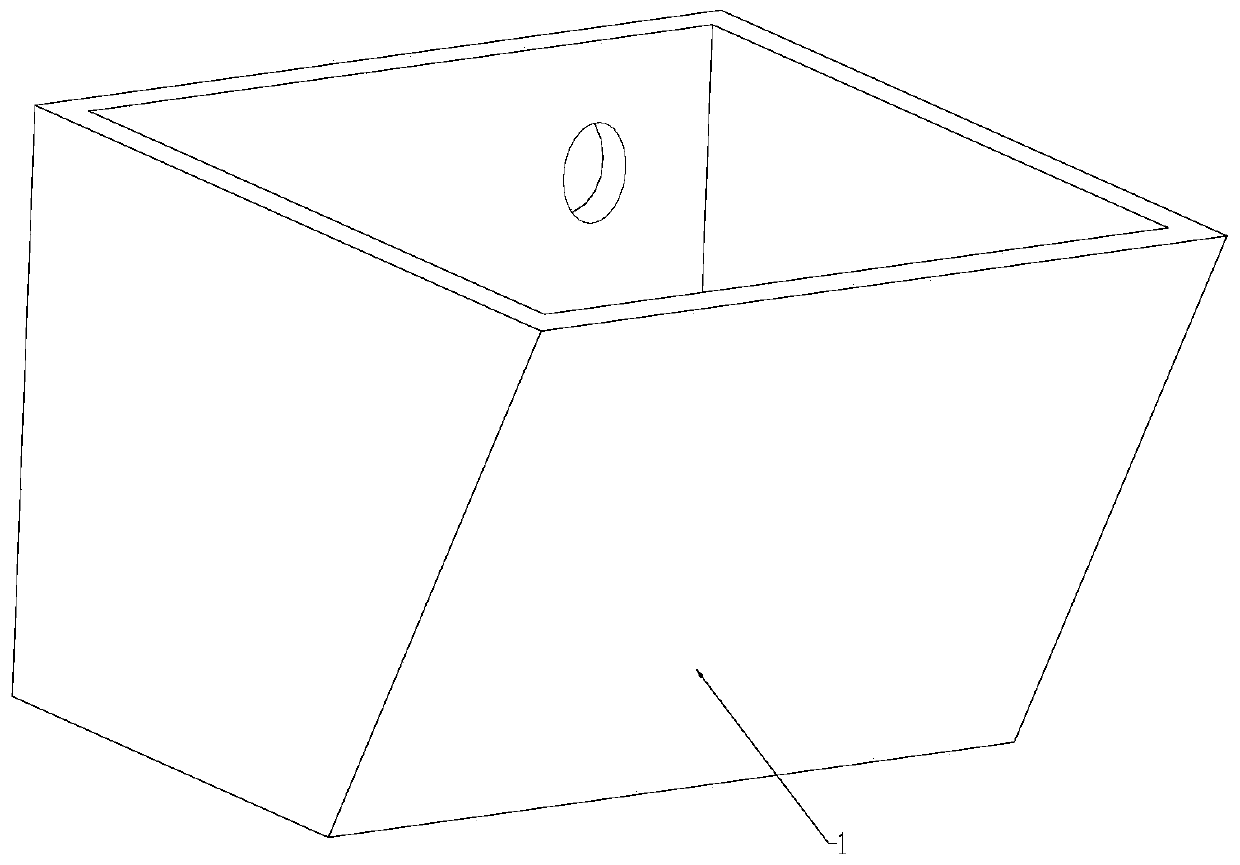

Image

Examples

Embodiment 1

[0033] A composition for preparing a three-dimensional greening cultivation container, comprising the following components in parts by weight: 850g of aluminate gelling material, 60g of fly ash, 30g of silica fume, 30g of mineral powder, 80g of organic material, and admixture 10g, fiber 5g and water 200g. The organic material is one or more of emulsion or resin, the emulsion is one or more of polyacrylate emulsion, styrene-acrylic emulsion, polyvinyl acetate emulsion, and the additive is water reducer, primer One or more of air agent and retarder, said fiber is polyvinyl alcohol fiber, polyvinyl chloride fiber, asbestos, polyester fiber, polyamide fiber, polyacrylonitrile fiber, polypropylene fiber, carbon fiber and glass fiber one or more of them.

[0034] The method for preparing a cultivation container by using the above-mentioned composition specifically comprises the following steps:

[0035] 1) Take aluminate cementitious material, fly ash, silica fume, mineral powder,...

Embodiment 2

[0041]A composition for preparing a three-dimensional greening cultivation container, comprising the following components in parts by weight: 900g of salt gelling material, 100g of fly ash, 50g of silica fume, 50g of mineral powder, 150g of organic material, 15g of additive, Fiber 15g and water 320g. The organic material is one or more of emulsion or resin, the emulsion is one or more of polyacrylate emulsion, styrene-acrylic emulsion, polyvinyl acetate emulsion, and the additive is water reducer, primer One or more of air agent and retarder, said fiber is polyvinyl alcohol fiber, polyvinyl chloride fiber, asbestos, polyester fiber, polyamide fiber, polyacrylonitrile fiber, polypropylene fiber, carbon fiber and glass fiber one or more of them.

[0042] The method for preparing a cultivation container by using the above-mentioned composition specifically comprises the following steps:

[0043] 1) Take aluminate cementitious material, fly ash, silica fume, mineral powder, orga...

Embodiment 3

[0049] A composition for preparing a three-dimensional greening cultivation container, comprising the following components in parts by weight: 1700g of aluminate gelling material, 200g of fly ash, 100g of silica fume, 200g of organic material, 25g of fiber, and 10g of water reducing agent and water 400g. The organic material is one or more of emulsion or resin, the emulsion is one or more of polyacrylate emulsion, styrene-acrylic emulsion, polyvinyl acetate emulsion, and the additive is water reducer, primer One or more of air agent and retarder, said fiber is polyvinyl alcohol fiber, polyvinyl chloride fiber, asbestos, polyester fiber, polyamide fiber, polyacrylonitrile fiber, polypropylene fiber, carbon fiber and glass fiber one or more of them.

[0050] The method for preparing a cultivation container by using the above-mentioned composition specifically comprises the following steps:

[0051] 1) Weigh 1700g of aluminate gelling material, 200g of fly ash, 100g of silica f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com